frequency counter PIC-Based Digital

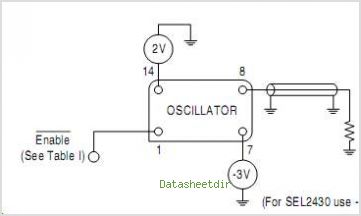

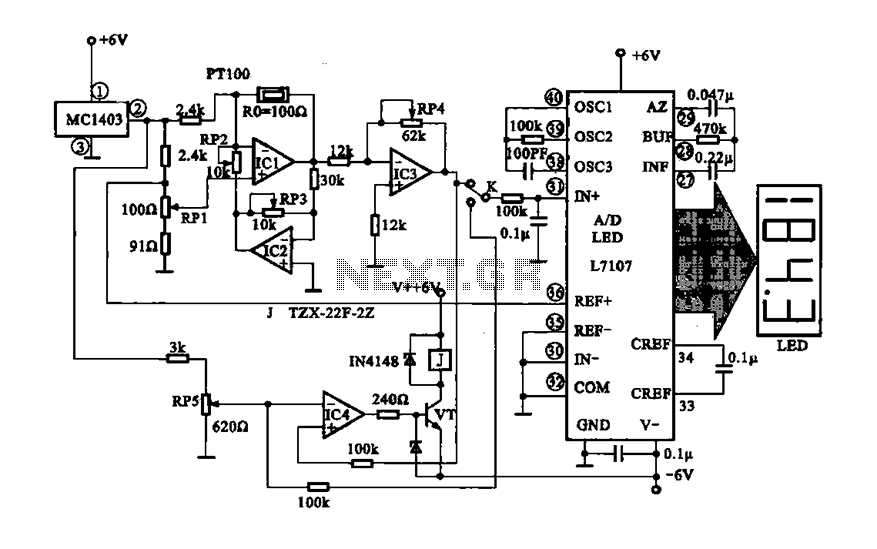

Power the frequency counter and adjust the coarse (top pot) and fine (bottom pot) controls to display zero frequency. Turn the pots counter-clockwise to achieve a zero reading. Occasionally, the counter may show only squares without digits. If this occurs, disconnect and reconnect the power supply to restore the display. Additionally, adjust the viewing angle of the display for optimal visibility. Install a 74HC4046 in the middle socket to allow VFO energy to reach the counter. Alternatively, remove the short on the VFO cable while keeping the HFO cable shorted. Caution is advised regarding reverse polarity connections, as connecting the frequency counter with reverse polarity can damage the voltage regulator (78LO5). To prevent this, a diode should be placed at the B+ input to the frequency counter, with the band side of the diode connected to the external power source. Set the 2/8 ceramic trim pot (labeled 14.068) to its midpoint, aligning the adjustment screw's slot with the capacitor pins, ensuring the rotor plate is positioned at the end with the arrow. If the frequency reading is excessively high, add a turn to the toroid, which may necessitate rewinding the toroid for a neat appearance, although a frequency reading above 15 MHz is generally uncommon. Secure the VFO toroid using any preferred method, such as plastic wrap, a 4-40 screw/nut with a rubber grommet, or candle wax (allow wax to cool before proceeding). Set the receiver to 40 Meters, with the bandpass switch on the 40/30 side and the crystal filter switch on the 40/20 side. One LED should illuminate next to the 10.545 relay. The offsets and adjustments are managed at Pins 12 and 13 of the PIC16C71, which are accessed via a four-pin set on the counter's rear. The chip includes 100K internal resistors that bias these pins to 5 volts, with two pins designated as grounds. Offsets are typically set by grounding the necessary pins using a jumper. For this receiver, wires are soldered to the left side pins (when viewed from the back), while the right side pins serve as grounds. The left side pins are marked as "upper jumper" and "lower jumper" in the instructions. There are two methods to connect the frequency counter to the receiver for automatic band switching: one involves a small interface unit utilizing diodes and two NPN transistors connected to the switches on Board 1 of the receiver, while the other uses a rotary switch. The two-section rotary switch is the simplest to wire, whether it consists of one wafer with two sections or two separate wafers. Although a single-wafer rotary switch can be used, it is more complex to wire. Note that the "Frequency Counter" output between the VFO amplifiers should not be used to drive the frequency counter, as this connection can overdrive the counter and introduce unwanted birdies into the receiver. Extensive research has been conducted to eliminate these birdies from the receiver. A recent discovery revealed that mounting the frequency counter in a specific manner minimizes birdies. Most noise from the counter originates from the LCD updating circuit, which is radiated by the display bezel and the display itself. Typically, good grounding techniques would mitigate this noise; however, an instance of insulating the display from ground resulted in a significant reduction of display noise in the receiver. It appears that a ground loop involving the display may cause noise to float within the receiver's ground circuit. Consequently, when mounting the frequency counter, it is imperative not to ground the display, allowing it to float instead. The only ground connection for the display should be at the PIC PCB ground connection located on the back of the counter. Notably, #12 solid copper wire, salvaged from residential wiring, fits conveniently within the mounting holes of the display.

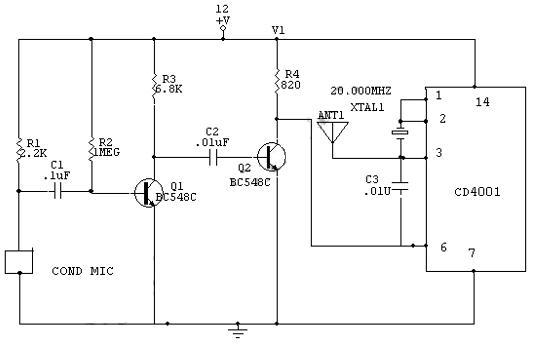

The frequency counter circuit is critical for accurately measuring and displaying frequency signals, particularly in radio frequency applications. The installation of the 74HC4046 phase-locked loop (PLL) is essential for frequency synthesis and demodulation, enabling the counter to process variable frequencies from the VFO. The careful adjustment of the coarse and fine pots ensures precise calibration, allowing for accurate readings that are crucial for tuning and signal analysis.

The use of diodes and NPN transistors in the automatic band switching interface provides a robust solution for integrating the frequency counter with the receiver, simplifying the user experience by automating frequency adjustments based on the selected band. The choice between a rotary switch or an interface unit offers flexibility in design, accommodating various user preferences and installation scenarios.

To mitigate noise issues, the frequency counter's mounting position and grounding scheme are paramount. The decision to allow the display to float rather than grounding it directly is a critical design consideration that addresses the interference caused by LCD circuits. This innovative approach demonstrates a practical understanding of electromagnetic interference (EMI) and grounding techniques in electronic designs.

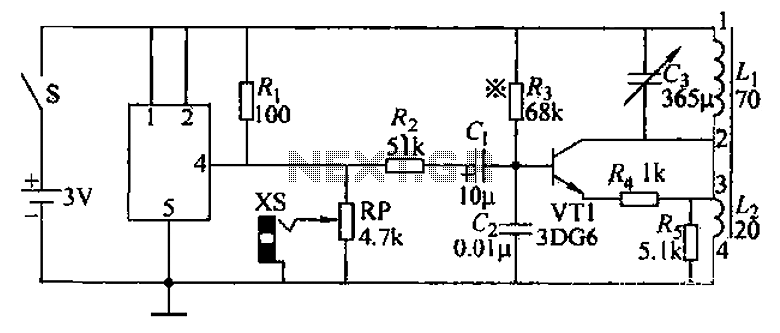

In summary, the integration of the frequency counter into the receiver system involves careful consideration of component selection, circuit design, and mechanical installation to ensure optimal performance and minimal noise interference. The outlined procedures and precautions are essential for achieving reliable operation and accurate frequency measurements in the field.Apply power to the frequency counter and set the coarse (top pot) and fine (bottom pot) adjustments to show zero frequency on the display. Turn the pots counter-clockwise to set to zero. Sometimes the counter will show all squares and no digits. Disconnect and re-apply power and the digits should show. Also, turn the viewing angle of the display to make sure they are visible. _Install a 74HC4046 in the middle socket. This will allow VFO energy to reach the counter. (Or remove the short on the VFO cable, leave the HFO cable shorted. ) Be very careful of reverse polarity connections. A reverse polarity connection to the frequency counter will blow the voltage regulator (78LO5). Use a diode at the B+ input to the Frequency Counter if you think you might make a mistake. Band side of the diode goes to the outside where you will be attaching power. _Set the 2/8 ceramic trim pot (labeled 14. 068) to its middle position. Line up the slot in the adjustment screw with the capacitor pins, with the rotor plate on the end with the arrow. The rotor plate is the part of the top with the metallic color. If the frequency is too high, add a turn to the toroid. (This may require rewinding the toroid for a clean appearance, but having the frequency read too high, >15MHz, is unlikely.

) _Secure the VFO toroid by whatever means you have decided. Some options are a small plastic wrap, a 4-40 screw/nut and 3/16" rubber grommet (cut to fit into the center of the toroid), or pour wax from a candle (let wax cool before proceeding). Picture _Set the receiver to 40 Meters. Bandpass switch to the 40/30 side and the Crystal Filter switch to the 40/20 side. One LED should be on next to the 10. 545 relay. The offsets and the adding/subtracting are done at Pins 12 and 13 of the PIC16C71. Pins 12 and 13 are brought out to a four pin set on the back of the counter. The chip has 100K internal resistors that bias the pins to 5 volts. Two of the pins are grounds and the offsets are normally set by using a jumper to ground the necessary pins.

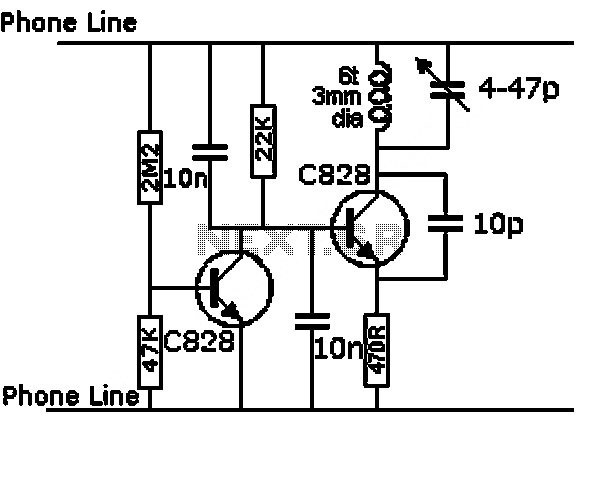

With this receiver, wires are soldered to the left side pins (looking at the back). The right side pins are grounds. The left side pins are labeled "upper jumper" and "lower jumper" in these instructions. There are two ways to connect the Frequency Counter to the receiver to achieve automatic switching of the bands on the counter. One is by using a small interface unit that uses diodes and two NPN transistors that connect to the switches on Board 1 of the receiver.

The second one is by using a rotary switch. The easiest one to wire is a two section rotary, either one wafer with two sections or two wafers. A rotary switch with one wafer can be used but is a little more complex to wire. Note: The "Frequency Counter" output between the VFO amplifiers will not be used to drive the Frequency Counter. This connection overdrives the Frequency Counter and causes birdies in the receiver. Getting the birdies of the counter out of the receiver has been researched for many hours. Just recently an accidental discovery showed the best way to mount the frequency counter for minimum birdies into the receiver.

Almost all the noise from the counter comes from the LCD updating circuit and is radiated by the display bezel and the display itself. Normally one would think that using good grounding techniques would eliminate that noise. However, when adjusting the counter frequencies one day, the display was insulated from ground and there was no display noise in the receiver!

A ground loop with the display must make the noise float in the ground circuit of the receiver. Therefore, when mounting the frequency counter, DO NOT ground the display, let it float! The only ground to the display should be at the back of the PIC PCB ground connection on the back of the counter. Turns out #12 solid copper wire scrapped from house wiring fits very nicely inside the mounting holes of the display.

🔗 External reference

The frequency counter circuit is critical for accurately measuring and displaying frequency signals, particularly in radio frequency applications. The installation of the 74HC4046 phase-locked loop (PLL) is essential for frequency synthesis and demodulation, enabling the counter to process variable frequencies from the VFO. The careful adjustment of the coarse and fine pots ensures precise calibration, allowing for accurate readings that are crucial for tuning and signal analysis.

The use of diodes and NPN transistors in the automatic band switching interface provides a robust solution for integrating the frequency counter with the receiver, simplifying the user experience by automating frequency adjustments based on the selected band. The choice between a rotary switch or an interface unit offers flexibility in design, accommodating various user preferences and installation scenarios.

To mitigate noise issues, the frequency counter's mounting position and grounding scheme are paramount. The decision to allow the display to float rather than grounding it directly is a critical design consideration that addresses the interference caused by LCD circuits. This innovative approach demonstrates a practical understanding of electromagnetic interference (EMI) and grounding techniques in electronic designs.

In summary, the integration of the frequency counter into the receiver system involves careful consideration of component selection, circuit design, and mechanical installation to ensure optimal performance and minimal noise interference. The outlined procedures and precautions are essential for achieving reliable operation and accurate frequency measurements in the field.Apply power to the frequency counter and set the coarse (top pot) and fine (bottom pot) adjustments to show zero frequency on the display. Turn the pots counter-clockwise to set to zero. Sometimes the counter will show all squares and no digits. Disconnect and re-apply power and the digits should show. Also, turn the viewing angle of the display to make sure they are visible. _Install a 74HC4046 in the middle socket. This will allow VFO energy to reach the counter. (Or remove the short on the VFO cable, leave the HFO cable shorted. ) Be very careful of reverse polarity connections. A reverse polarity connection to the frequency counter will blow the voltage regulator (78LO5). Use a diode at the B+ input to the Frequency Counter if you think you might make a mistake. Band side of the diode goes to the outside where you will be attaching power. _Set the 2/8 ceramic trim pot (labeled 14. 068) to its middle position. Line up the slot in the adjustment screw with the capacitor pins, with the rotor plate on the end with the arrow. The rotor plate is the part of the top with the metallic color. If the frequency is too high, add a turn to the toroid. (This may require rewinding the toroid for a clean appearance, but having the frequency read too high, >15MHz, is unlikely.

) _Secure the VFO toroid by whatever means you have decided. Some options are a small plastic wrap, a 4-40 screw/nut and 3/16" rubber grommet (cut to fit into the center of the toroid), or pour wax from a candle (let wax cool before proceeding). Picture _Set the receiver to 40 Meters. Bandpass switch to the 40/30 side and the Crystal Filter switch to the 40/20 side. One LED should be on next to the 10. 545 relay. The offsets and the adding/subtracting are done at Pins 12 and 13 of the PIC16C71. Pins 12 and 13 are brought out to a four pin set on the back of the counter. The chip has 100K internal resistors that bias the pins to 5 volts. Two of the pins are grounds and the offsets are normally set by using a jumper to ground the necessary pins.

With this receiver, wires are soldered to the left side pins (looking at the back). The right side pins are grounds. The left side pins are labeled "upper jumper" and "lower jumper" in these instructions. There are two ways to connect the Frequency Counter to the receiver to achieve automatic switching of the bands on the counter. One is by using a small interface unit that uses diodes and two NPN transistors that connect to the switches on Board 1 of the receiver.

The second one is by using a rotary switch. The easiest one to wire is a two section rotary, either one wafer with two sections or two wafers. A rotary switch with one wafer can be used but is a little more complex to wire. Note: The "Frequency Counter" output between the VFO amplifiers will not be used to drive the Frequency Counter. This connection overdrives the Frequency Counter and causes birdies in the receiver. Getting the birdies of the counter out of the receiver has been researched for many hours. Just recently an accidental discovery showed the best way to mount the frequency counter for minimum birdies into the receiver.

Almost all the noise from the counter comes from the LCD updating circuit and is radiated by the display bezel and the display itself. Normally one would think that using good grounding techniques would eliminate that noise. However, when adjusting the counter frequencies one day, the display was insulated from ground and there was no display noise in the receiver!

A ground loop with the display must make the noise float in the ground circuit of the receiver. Therefore, when mounting the frequency counter, DO NOT ground the display, let it float! The only ground to the display should be at the back of the PIC PCB ground connection on the back of the counter. Turns out #12 solid copper wire scrapped from house wiring fits very nicely inside the mounting holes of the display.

🔗 External reference