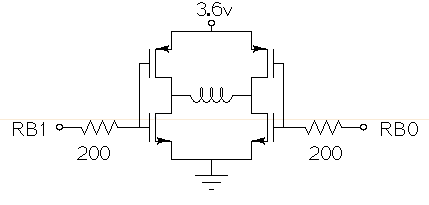

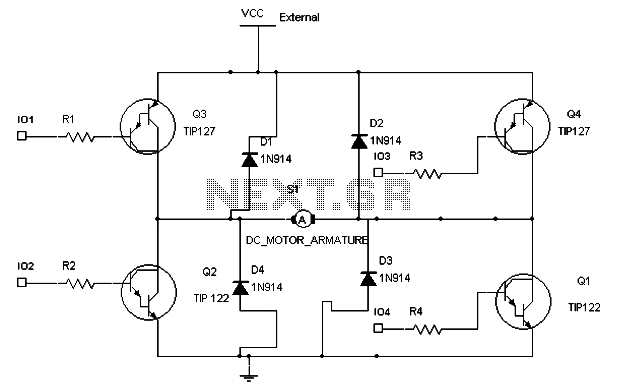

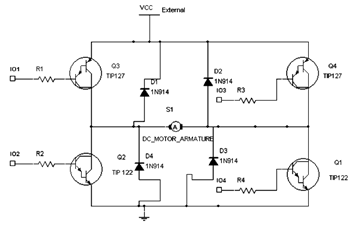

H-Bridge

The HandyBoard operates both pads using the positive supply from the battery. When one of the motors is intended to turn, the HandyBoard activates the corresponding pin to 0V. The voltage difference between the two pads causes the motor to rotate. The transistors used are TIP 120 and TIP 125, although they can be replaced with more modern alternatives. These transistors are designed to handle a continuous current of 5 mA with the appropriate heatsink. They must be soldered in a top-down orientation to allow for heatsink attachment. The infrared (IR) LED and the IR resistor need to be shielded from ambient light. When the fuse is intact, the IR LED illuminates the IR resistor, which the HandyBoard can detect through any analog input port. If the fuse is blown, the IR LED will not operate, leading to an increase in the resistance of the IR resistor, which can also be detected by the HandyBoard.

The HandyBoard circuit utilizes a straightforward control mechanism for motor operation, leveraging the difference in voltage across two pads to facilitate rotation. The circuit includes a pair of TIP120 and TIP125 transistors that function as switches to control the motor's direction by toggling the voltage levels on the pads. When a motor is commanded to turn, the HandyBoard drives the appropriate control pin low (0V), creating a potential difference that energizes the motor.

The transistors are capable of managing a continuous current of 5 mA, necessitating the use of heatsinks to dissipate heat generated during operation. These components must be installed in a top-down configuration to ensure proper attachment of the heatsink, which is critical for maintaining operational efficiency and preventing thermal overload.

Incorporating an IR LED and an IR resistor into the circuit allows for monitoring the status of the fuse. The IR LED emits light that illuminates the IR resistor; when the fuse is functional, the HandyBoard can detect the resulting signal through its analog input. Conversely, a blown fuse results in the IR LED not functioning, causing the IR resistor's resistance to increase significantly. This change in resistance can also be monitored by the HandyBoard, providing an effective means of fuse status detection.

To enhance the performance of the IR components, it is essential to shield them from ambient light, which could interfere with the circuit's operation. This can be achieved through the use of enclosures or strategic placement within the overall design. Proper attention to these details ensures reliable motor control and effective fuse monitoring within the HandyBoard circuit.The HandyBoard drives both pads at the positive supply of the battery. When one of the motor is supposed to turn, the handyboard drives the appropriate pin at 0V. The difference between two pads makes the motor turn. The Transistors are TIP 120 and TIP 125 but could be changed for more recents ones. They are supposed to drive 5 mA continous with a ppropriate HeatSink. They must be soldered TOP DOWN in order to be able to connect a heatsink. The IR Led and IR Resistor should be protected from the ambiant light. When the fuse is OK, the IR Led is illuminating the IR Resistor and the HandyBoard can detect it throught any analog input port. If the fuse is blowed, the IR Led isn`t working and the IR Resistor increases it`s resistance and this can be detected by the HandyBoard.

🔗 External reference

The HandyBoard circuit utilizes a straightforward control mechanism for motor operation, leveraging the difference in voltage across two pads to facilitate rotation. The circuit includes a pair of TIP120 and TIP125 transistors that function as switches to control the motor's direction by toggling the voltage levels on the pads. When a motor is commanded to turn, the HandyBoard drives the appropriate control pin low (0V), creating a potential difference that energizes the motor.

The transistors are capable of managing a continuous current of 5 mA, necessitating the use of heatsinks to dissipate heat generated during operation. These components must be installed in a top-down configuration to ensure proper attachment of the heatsink, which is critical for maintaining operational efficiency and preventing thermal overload.

Incorporating an IR LED and an IR resistor into the circuit allows for monitoring the status of the fuse. The IR LED emits light that illuminates the IR resistor; when the fuse is functional, the HandyBoard can detect the resulting signal through its analog input. Conversely, a blown fuse results in the IR LED not functioning, causing the IR resistor's resistance to increase significantly. This change in resistance can also be monitored by the HandyBoard, providing an effective means of fuse status detection.

To enhance the performance of the IR components, it is essential to shield them from ambient light, which could interfere with the circuit's operation. This can be achieved through the use of enclosures or strategic placement within the overall design. Proper attention to these details ensures reliable motor control and effective fuse monitoring within the HandyBoard circuit.The HandyBoard drives both pads at the positive supply of the battery. When one of the motor is supposed to turn, the handyboard drives the appropriate pin at 0V. The difference between two pads makes the motor turn. The Transistors are TIP 120 and TIP 125 but could be changed for more recents ones. They are supposed to drive 5 mA continous with a ppropriate HeatSink. They must be soldered TOP DOWN in order to be able to connect a heatsink. The IR Led and IR Resistor should be protected from the ambiant light. When the fuse is OK, the IR Led is illuminating the IR Resistor and the HandyBoard can detect it throught any analog input port. If the fuse is blowed, the IR Led isn`t working and the IR Resistor increases it`s resistance and this can be detected by the HandyBoard.

🔗 External reference