heater with ckm005 microcontroller

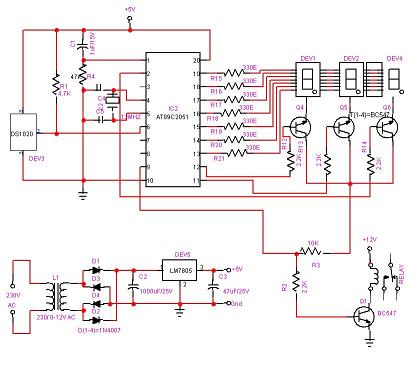

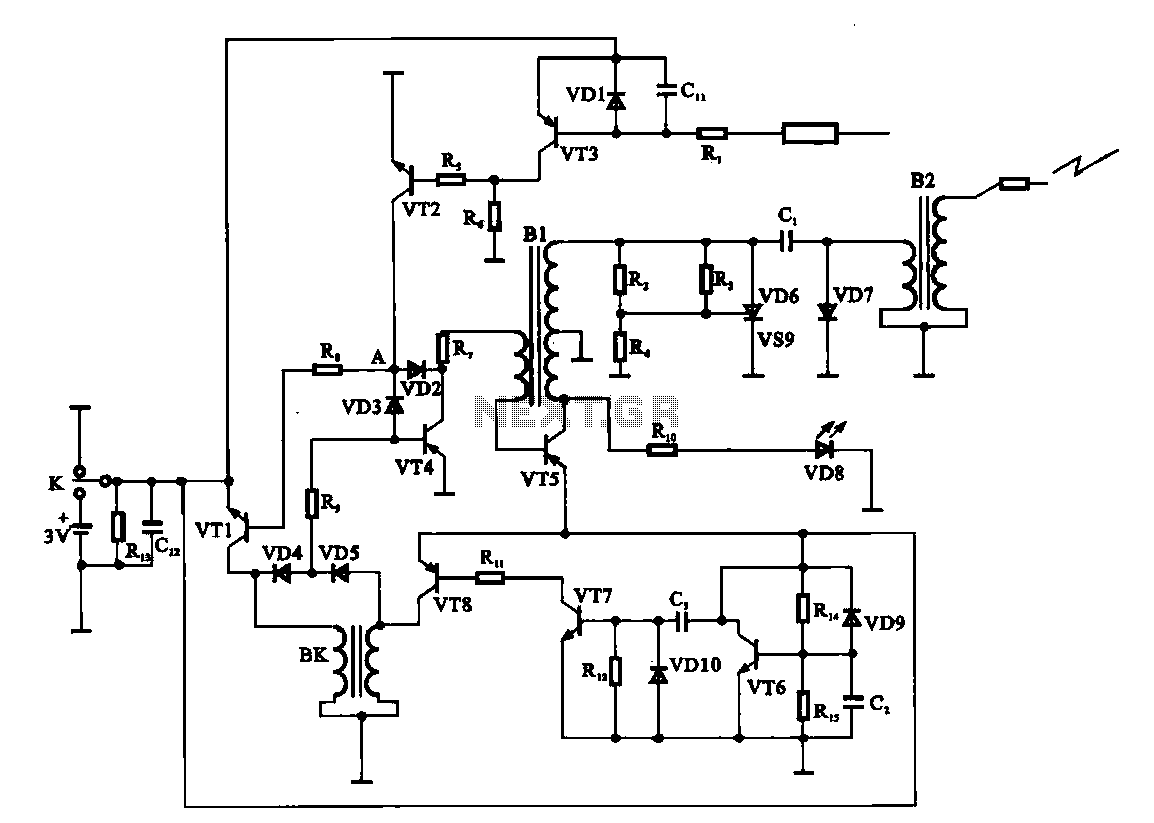

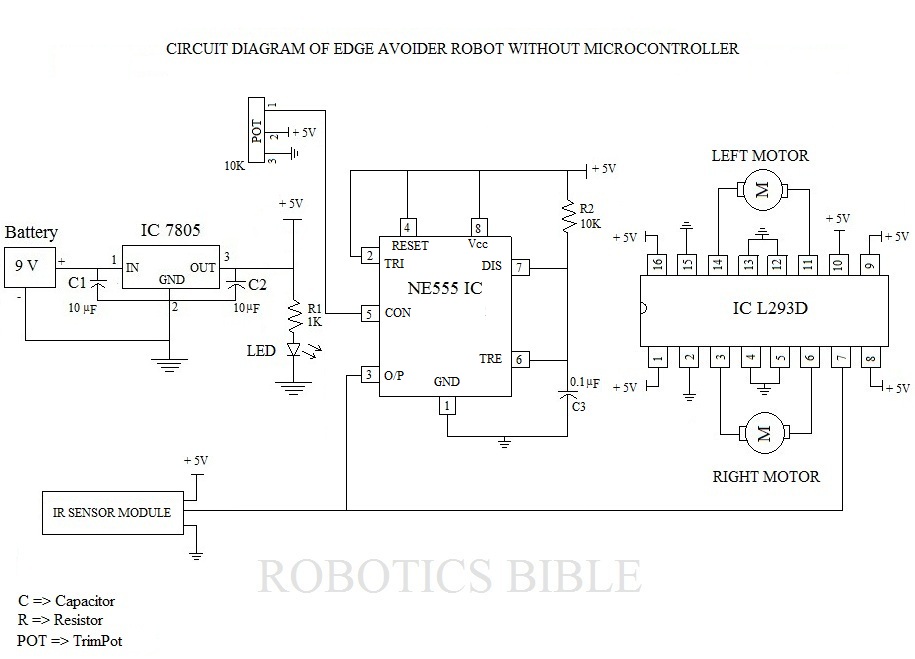

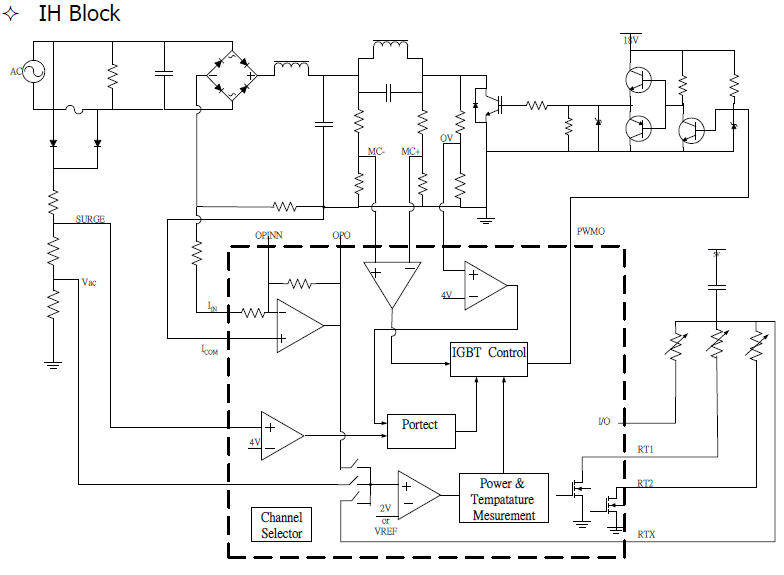

The control board features a 7-segment LED display for temperature and power readouts at the front. A fan is mounted at the base of the unit alongside an induction coil, which appears to use a similar gauge of Litz wire as the Burton unit but has a more aesthetically pleasing coil former. It is hoped that the coil is not glued together in a solid shellac mass like the Burton, allowing for disassembly and re-winding into a cylinder. Aside from some melted black plastic formers, there seems to be nothing overly problematic holding the coil in place, which is encouraging. The power stage board presents a clean and simplified design, with an input filter/current feeding inductor located in the upper left, robust blue capacitors for the resonant tank and feed tank, and significantly fewer components compared to the Burton unit. This compact design likely reduces production costs. The power stage is driven by a single 25N120 IGBT, capable of handling 25A and 1200V. While it may be slower for chopper-based converters, it excels in high-current soft-switching applications. It is noteworthy that this induction cooker operates with only one IGBT, which raises questions about whether it is lower powered than the Burton or if only one IGBT suffices to deliver adequate power in a 230V environment. The layout is cleaner and more compact, with clear white silkscreen diagramming for easier circuit tracing. Some power stage components have been labeled in red with their values. The heatsink is likely cooling the bridge rectifier and IGBTs, along with the large resonant capacitors. An 8-pin flyback IC is present near a small yellow transformer, likely generating an 18V (or 12V) main rail for the IGBT gate driver. A 7805 linear regulator is also present, providing a 5V rail for the control circuitry. Notably, there is no LM339 or a chaotic arrangement of discrete components for voltage sensing, current sensing, PWM, and fault protection. Instead, these functions appear to be integrated into a 20-pin mystery IC labeled 200D-BUP, which likely denotes the model number (200W or 230V) and revision code for the cooker. Further investigation reveals a CKM005ND20J component, with "20J" probably indicating the package code and "ND" possibly representing a product option. Initial searches suggest that CKM005 may be a microcontroller, with limited information available but some references indicating it is designed for induction cooker applications.

The control board of the induction cooker integrates a 7-segment LED display, which serves as an interface for real-time temperature and power monitoring. The presence of a fan at the base of the unit is critical for thermal management, ensuring efficient operation of the induction coil, which is constructed using Litz wire for optimal performance in high-frequency applications. The coil former's design enhances electromagnetic efficiency and minimizes losses, a crucial aspect in induction heating technology.

The power stage board is characterized by its streamlined design, which not only simplifies assembly but also enhances reliability. The inclusion of an input filter/current feeding inductor is essential for smoothing current flow and reducing electromagnetic interference (EMI). The choice of large blue capacitors for the resonant and feed tanks indicates a focus on maintaining stable operation under varying load conditions. The reduced component count compared to previous models suggests advancements in design efficiency, likely contributing to cost-effectiveness in production.

The use of a single 25N120 IGBT is particularly noteworthy, as it demonstrates the ability to achieve high power output with fewer components. This IGBT is well-suited for soft-switching applications, which are critical in induction heating for minimizing switching losses and improving overall efficiency. The design's compactness and clarity, aided by thoughtful silkscreen labeling, facilitate troubleshooting and maintenance.

The thermal management system, including the heatsink, is designed to dissipate heat generated by the bridge rectifier and IGBT, ensuring that the components operate within safe temperature limits. The use of a flyback IC and transformer for generating auxiliary voltages indicates a well-thought-out power supply architecture, crucial for stable operation of the control circuitry.

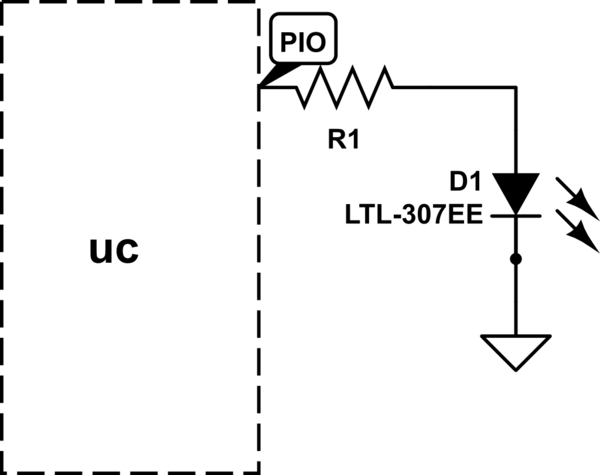

The integration of a microcontroller, likely the CKM005, reflects a shift towards more sophisticated control mechanisms within induction cookers. This microcontroller likely handles various functions such as power regulation, fault detection, and user interface management, streamlining the overall design and improving performance. The absence of traditional discrete components for sensing and control suggests a modern approach to circuit design, emphasizing reliability and efficiency.

In summary, this induction cooker exemplifies advancements in electronic design, focusing on efficiency, compactness, and ease of use while maintaining robust performance characteristics suitable for modern cooking applications.We see the control board with 7-segment LED display for temp and power readout up in front. The obligatory fan mounted down in the base of the unit, and a lovely induction coil. Looks like about the same gauge Litz wire as the Burton unit but with a much nicer coil former. We`re hoping it`s not all glued together in a big shellac clump like the Burton, so the coil can be disassembled and re-wound into a cylinder. Aside from the melted black plastic formers, it APPEARS there`s nothing too troublesome holding the coil in place, which is a very encouraging sign. Next comes the power stage board. Again, very clean and simplified design. There`s the input filter/current feeding inductor up there in the upper left, the nice hefty blue caps for the resonant tank and feed tank, and MANY fewer components than the Burton.

Compact, and probably much cheaper to produce. Ahh, the big boy himself. The venerable 25N120 IGBT. 25A and 1200V of pure power switching fury. A little slow for chopper based converters, but for this type of high current soft-switching application this device cannot be beat. It`s interesting that this cooker gets away with only a single IGBT not sure if it`s lower powered than the Burton, or whether only a single IGBT is needed to get enough power over there in 230V land.

Lucky bastards! Again, cleaner and more compact. And nicely diagrammed in white silkscreen to make circuit tracing easier! Excellent! Ad has been kind enough to label a few of the power stage components for us in red, along with their values. So that`s it for the extended tour of the insides of the new device. We`ll continue on with the remainder of the original post from yesterday as we puzzle out the function of the power stage.

But rest assured, we are now opening eBay and looking for this little gem to see for ourselves what treasures it holds. Let`s take a look and see what we can recognize. We can see the heatsink, presumably cooling the bridge rectifier and IGBTs, as well as the big fat resonant caps (light blue).

The same old 8-pin flyback IC appears near the little yellow transformer, probably making the same old 18V (or 12V) main rail for running the gate driver of the IGBT. And is that the good old 7805 linear regulator Must be the same old 5V rail for the control circuitry.

But no LM339 And no ratsnest of discrete components to do the voltage sensing, current sensing, PWM, fault protection, etc Cool! It appears to have all been replaced by a 20-pin mystery IC with the 200D-BUP label. This code is probably the model number (200W or 230V ) and revision code for the cooker. Now What`s beneath this little lady`s skirt Ad obliges to give us a peek in this next pic. CKM005ND20J. Huh 20J is probably the package code, ND may be a product option. So CKM005 is what we start googling. Not much. Guessing it`s a microcontroller gets a few sporadic hits on those junk pages listing every IC in the dictionary for sale.

So some confirmation, but not much info. Some references to EMC corporation, and other chips such as CKM002 tell us that it probably IS a microcontroller and is specifically designed for the induction cooker application. Their verbage is usually something about MCU for IH Cooker , so let`s dig even deeper. Assuming that this device is prod 🔗 External reference

The control board of the induction cooker integrates a 7-segment LED display, which serves as an interface for real-time temperature and power monitoring. The presence of a fan at the base of the unit is critical for thermal management, ensuring efficient operation of the induction coil, which is constructed using Litz wire for optimal performance in high-frequency applications. The coil former's design enhances electromagnetic efficiency and minimizes losses, a crucial aspect in induction heating technology.

The power stage board is characterized by its streamlined design, which not only simplifies assembly but also enhances reliability. The inclusion of an input filter/current feeding inductor is essential for smoothing current flow and reducing electromagnetic interference (EMI). The choice of large blue capacitors for the resonant and feed tanks indicates a focus on maintaining stable operation under varying load conditions. The reduced component count compared to previous models suggests advancements in design efficiency, likely contributing to cost-effectiveness in production.

The use of a single 25N120 IGBT is particularly noteworthy, as it demonstrates the ability to achieve high power output with fewer components. This IGBT is well-suited for soft-switching applications, which are critical in induction heating for minimizing switching losses and improving overall efficiency. The design's compactness and clarity, aided by thoughtful silkscreen labeling, facilitate troubleshooting and maintenance.

The thermal management system, including the heatsink, is designed to dissipate heat generated by the bridge rectifier and IGBT, ensuring that the components operate within safe temperature limits. The use of a flyback IC and transformer for generating auxiliary voltages indicates a well-thought-out power supply architecture, crucial for stable operation of the control circuitry.

The integration of a microcontroller, likely the CKM005, reflects a shift towards more sophisticated control mechanisms within induction cookers. This microcontroller likely handles various functions such as power regulation, fault detection, and user interface management, streamlining the overall design and improving performance. The absence of traditional discrete components for sensing and control suggests a modern approach to circuit design, emphasizing reliability and efficiency.

In summary, this induction cooker exemplifies advancements in electronic design, focusing on efficiency, compactness, and ease of use while maintaining robust performance characteristics suitable for modern cooking applications.We see the control board with 7-segment LED display for temp and power readout up in front. The obligatory fan mounted down in the base of the unit, and a lovely induction coil. Looks like about the same gauge Litz wire as the Burton unit but with a much nicer coil former. We`re hoping it`s not all glued together in a big shellac clump like the Burton, so the coil can be disassembled and re-wound into a cylinder. Aside from the melted black plastic formers, it APPEARS there`s nothing too troublesome holding the coil in place, which is a very encouraging sign. Next comes the power stage board. Again, very clean and simplified design. There`s the input filter/current feeding inductor up there in the upper left, the nice hefty blue caps for the resonant tank and feed tank, and MANY fewer components than the Burton.

Compact, and probably much cheaper to produce. Ahh, the big boy himself. The venerable 25N120 IGBT. 25A and 1200V of pure power switching fury. A little slow for chopper based converters, but for this type of high current soft-switching application this device cannot be beat. It`s interesting that this cooker gets away with only a single IGBT not sure if it`s lower powered than the Burton, or whether only a single IGBT is needed to get enough power over there in 230V land.

Lucky bastards! Again, cleaner and more compact. And nicely diagrammed in white silkscreen to make circuit tracing easier! Excellent! Ad has been kind enough to label a few of the power stage components for us in red, along with their values. So that`s it for the extended tour of the insides of the new device. We`ll continue on with the remainder of the original post from yesterday as we puzzle out the function of the power stage.

But rest assured, we are now opening eBay and looking for this little gem to see for ourselves what treasures it holds. Let`s take a look and see what we can recognize. We can see the heatsink, presumably cooling the bridge rectifier and IGBTs, as well as the big fat resonant caps (light blue).

The same old 8-pin flyback IC appears near the little yellow transformer, probably making the same old 18V (or 12V) main rail for running the gate driver of the IGBT. And is that the good old 7805 linear regulator Must be the same old 5V rail for the control circuitry.

But no LM339 And no ratsnest of discrete components to do the voltage sensing, current sensing, PWM, fault protection, etc Cool! It appears to have all been replaced by a 20-pin mystery IC with the 200D-BUP label. This code is probably the model number (200W or 230V ) and revision code for the cooker. Now What`s beneath this little lady`s skirt Ad obliges to give us a peek in this next pic. CKM005ND20J. Huh 20J is probably the package code, ND may be a product option. So CKM005 is what we start googling. Not much. Guessing it`s a microcontroller gets a few sporadic hits on those junk pages listing every IC in the dictionary for sale.

So some confirmation, but not much info. Some references to EMC corporation, and other chips such as CKM002 tell us that it probably IS a microcontroller and is specifically designed for the induction cooker application. Their verbage is usually something about MCU for IH Cooker , so let`s dig even deeper. Assuming that this device is prod 🔗 External reference