how to make capacitive discharge

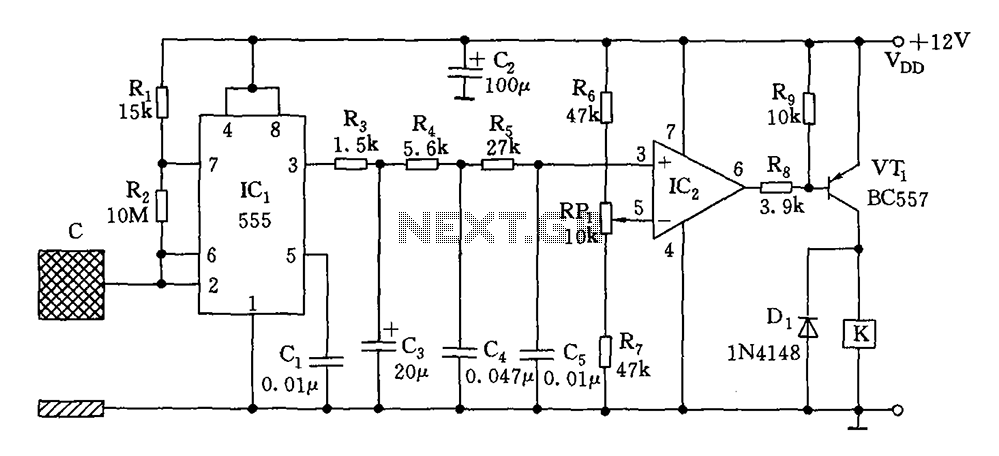

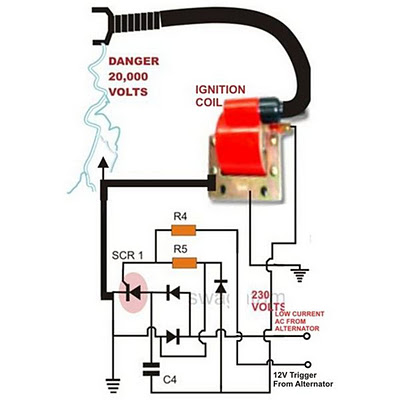

The ignition process in any vehicle is crucial as it is the stage that allows the vehicle to start. Historically, a circuit breaker unit was used to initiate this process. However, modern vehicles utilize a more efficient and durable mechanism known as the capacitor discharge ignition (CDI) system. This system incorporates an electronic circuit that functions similarly to the traditional contact breaker but operates in a solid-state manner. The ignition system in vehicles is responsible for igniting the fuel mixture to initiate the engine and drive mechanisms. The ignition coil, commonly found in vehicles, is designed to step up the input voltage. Since the voltage from the alternator may not provide sufficient current directly to the ignition coil, a CDI unit is employed to collect and release the alternator's power in a compact and high-current manner. The capacitor discharge ignition circuit consists of several diodes, resistors, a silicon-controlled rectifier (SCR), and a high-voltage capacitor. One input source provides a low voltage of around 12 volts, while the other input is derived from a high-voltage tap of the alternator, generating approximately 100 volts. This input is rectified by the diodes and converted to 100 volts DC, which is then stored in the high-voltage capacitor. This action creates magnetic induction within the coil, and the CDI's high current and voltage input are further amplified to extremely high levels at the secondary winding of the coil. The resulting high voltage initiates arcing across the spark plug points, producing the necessary ignition sparks for the ignition process.

The capacitor discharge ignition (CDI) system is a critical component in modern vehicle ignition systems, providing enhanced performance and reliability. The circuit's architecture typically includes a low-voltage input from the vehicle's battery, which serves as a baseline for operation. The alternator's high-voltage output is tapped directly, often utilizing a transformer or a specific winding designed to handle the increased voltage. The diodes in the circuit serve dual purposes: they rectify the alternating current (AC) generated by the alternator into direct current (DC) and protect the circuit from reverse voltage spikes.

The SCR plays a pivotal role in controlling the timing of the discharge from the capacitor to the ignition coil. When the SCR is triggered, it allows the stored energy in the capacitor to flow into the primary winding of the ignition coil. The magnetic field generated in the coil induces a much higher voltage in the secondary winding, which is then directed to the spark plugs. This process is crucial for achieving the rapid ignition needed for efficient engine performance.

The high-voltage capacitor is essential for storing energy quickly and releasing it in a controlled manner. Its ability to handle high voltage and discharge rapidly makes it ideal for this application. The design of the CDI system minimizes energy loss, ensuring that more power is available for ignition, which translates to better engine response and improved fuel efficiency.

In summary, the capacitor discharge ignition system represents a significant advancement over traditional ignition methods, combining solid-state technology with efficient energy management to enhance vehicle performance. The integration of various electronic components allows for precise control over the ignition timing and energy delivery, ultimately leading to more reliable engine operation.The ignition process in any vehicle becomes the heart of the entire system as without this stage the vehicle just won`t start. To initiate the process, earlier we use to have the circuit breaker unit for the required actions. Nowadays a more efficient and long lasting mechanism has been developed for the ignitions in vehicles, called the capac

itor discharge ignition system. It incorporate an electronic circuit precisely functions like the old contact breaker, but in a solid-state electronic manner. Basically as the name suggest, ignition system in vehicles refers to the process in which the fuel mixture is ignited for initiating the engine and the drive mechanisms.

The ignition coil, which is very popular and we all have seen them in our vehicles is especially designed for the above stepping up of the input source voltage However the voltage from the alternator cannot be directly fed to the ignition coil because the source may be low in current, therefore we employ a CDI unit or a capacitive discharge unit for collecting and releasing the alternator power in succession in order to make the output compact and high with current. Referring to the above capacitor discharge ignitioncircuit diagram, we see a simple configuration consisting of a few diodes, resistors, a SCR and a single high voltage capacitor.

One source is a low voltage around 12 volts while the other input is taken from the relatively high voltage tap of the alternator, generating around a 100 volts. The 100 volts input is suitably rectified by the diodes and converted to 100 volts DC. This voltage is stored inside the high voltage capacitor instantaneously. The action generates a magnetic induction inside the coil and the input from the CDI which is high in current and voltage is further enhanced to extremely high levels at the secondary winding of the coil.

The voltage being very high in potential starts arcing across the points of the spark plug, generating the required ignition sparks for the ignition process. 🔗 External reference

The capacitor discharge ignition (CDI) system is a critical component in modern vehicle ignition systems, providing enhanced performance and reliability. The circuit's architecture typically includes a low-voltage input from the vehicle's battery, which serves as a baseline for operation. The alternator's high-voltage output is tapped directly, often utilizing a transformer or a specific winding designed to handle the increased voltage. The diodes in the circuit serve dual purposes: they rectify the alternating current (AC) generated by the alternator into direct current (DC) and protect the circuit from reverse voltage spikes.

The SCR plays a pivotal role in controlling the timing of the discharge from the capacitor to the ignition coil. When the SCR is triggered, it allows the stored energy in the capacitor to flow into the primary winding of the ignition coil. The magnetic field generated in the coil induces a much higher voltage in the secondary winding, which is then directed to the spark plugs. This process is crucial for achieving the rapid ignition needed for efficient engine performance.

The high-voltage capacitor is essential for storing energy quickly and releasing it in a controlled manner. Its ability to handle high voltage and discharge rapidly makes it ideal for this application. The design of the CDI system minimizes energy loss, ensuring that more power is available for ignition, which translates to better engine response and improved fuel efficiency.

In summary, the capacitor discharge ignition system represents a significant advancement over traditional ignition methods, combining solid-state technology with efficient energy management to enhance vehicle performance. The integration of various electronic components allows for precise control over the ignition timing and energy delivery, ultimately leading to more reliable engine operation.The ignition process in any vehicle becomes the heart of the entire system as without this stage the vehicle just won`t start. To initiate the process, earlier we use to have the circuit breaker unit for the required actions. Nowadays a more efficient and long lasting mechanism has been developed for the ignitions in vehicles, called the capac

itor discharge ignition system. It incorporate an electronic circuit precisely functions like the old contact breaker, but in a solid-state electronic manner. Basically as the name suggest, ignition system in vehicles refers to the process in which the fuel mixture is ignited for initiating the engine and the drive mechanisms.

The ignition coil, which is very popular and we all have seen them in our vehicles is especially designed for the above stepping up of the input source voltage However the voltage from the alternator cannot be directly fed to the ignition coil because the source may be low in current, therefore we employ a CDI unit or a capacitive discharge unit for collecting and releasing the alternator power in succession in order to make the output compact and high with current. Referring to the above capacitor discharge ignitioncircuit diagram, we see a simple configuration consisting of a few diodes, resistors, a SCR and a single high voltage capacitor.

One source is a low voltage around 12 volts while the other input is taken from the relatively high voltage tap of the alternator, generating around a 100 volts. The 100 volts input is suitably rectified by the diodes and converted to 100 volts DC. This voltage is stored inside the high voltage capacitor instantaneously. The action generates a magnetic induction inside the coil and the input from the CDI which is high in current and voltage is further enhanced to extremely high levels at the secondary winding of the coil.

The voltage being very high in potential starts arcing across the points of the spark plug, generating the required ignition sparks for the ignition process. 🔗 External reference