IC Encoder Chip

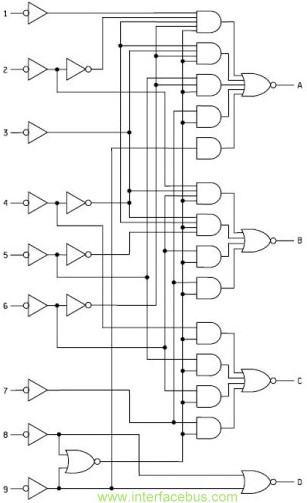

This function is not complex and can be easily implemented in a Programmable Logic Device (PLD) or Field Programmable Gate Array (FPGA). However, implementing this function in a small PLD may consume most of the device's I/O pins, which could undermine the advantages of using a PLD. The cost of the PLD may exceed the benefits if most of its resources are utilized for this simple function rather than opting for a more economical solution. Nevertheless, it is feasible to implement this function in a PLD while retaining sufficient space and I/O pins for additional functionalities, thereby allowing the PLD to serve as a replacement for multiple glue logic integrated circuits (ICs).

The implementation of a simple function in a PLD or FPGA offers flexibility and adaptability in electronic design. The choice of using a PLD or FPGA depends on the complexity of the function, the available resources, and the overall design requirements. When considering a small PLD, careful analysis is necessary to ensure that the I/O pin allocation does not become a limiting factor. Each I/O pin consumed reduces the capability to add further functionalities, which could lead to inefficiencies in the design process.

In cases where the function is straightforward, utilizing a less expensive alternative may be more beneficial, provided it meets the performance criteria. However, if the design anticipates future expansions or modifications, a PLD can be a strategic choice. It allows for reprogramming and adjustments without the need to redesign the entire circuit, thus offering long-term value.

When designing with PLDs, it is essential to create a schematic that clearly outlines the connections between the PLD and other components in the circuit. This includes defining the power supply connections, ground connections, and the routing of I/O pins to external devices. Additionally, the schematic should illustrate any necessary logic gates, flip-flops, or multiplexers that may be required to implement the function effectively.

In conclusion, while the initial implementation of a simple function in a PLD may seem straightforward, careful consideration must be given to resource management, cost implications, and future scalability. The ability to replace multiple glue logic ICs with a single PLD can lead to a more streamlined and efficient design, making it a valuable tool in modern electronic engineering.This is not a complex function and could be easily coded into a PLD or FPGA. However implementing this function into a small PLD might just use up most of the chip`s I/O pins and defeat the purpose of the PLD. That is; spending more for the PLD, than using most of it up implementing a much cheaper part. However it could be possible to implement th is function in a PLD and have space and I/O pins left over to implement additions functions, and using a PLD to replace one than one glue logic IC. 🔗 External reference

The implementation of a simple function in a PLD or FPGA offers flexibility and adaptability in electronic design. The choice of using a PLD or FPGA depends on the complexity of the function, the available resources, and the overall design requirements. When considering a small PLD, careful analysis is necessary to ensure that the I/O pin allocation does not become a limiting factor. Each I/O pin consumed reduces the capability to add further functionalities, which could lead to inefficiencies in the design process.

In cases where the function is straightforward, utilizing a less expensive alternative may be more beneficial, provided it meets the performance criteria. However, if the design anticipates future expansions or modifications, a PLD can be a strategic choice. It allows for reprogramming and adjustments without the need to redesign the entire circuit, thus offering long-term value.

When designing with PLDs, it is essential to create a schematic that clearly outlines the connections between the PLD and other components in the circuit. This includes defining the power supply connections, ground connections, and the routing of I/O pins to external devices. Additionally, the schematic should illustrate any necessary logic gates, flip-flops, or multiplexers that may be required to implement the function effectively.

In conclusion, while the initial implementation of a simple function in a PLD may seem straightforward, careful consideration must be given to resource management, cost implications, and future scalability. The ability to replace multiple glue logic ICs with a single PLD can lead to a more streamlined and efficient design, making it a valuable tool in modern electronic engineering.This is not a complex function and could be easily coded into a PLD or FPGA. However implementing this function into a small PLD might just use up most of the chip`s I/O pins and defeat the purpose of the PLD. That is; spending more for the PLD, than using most of it up implementing a much cheaper part. However it could be possible to implement th is function in a PLD and have space and I/O pins left over to implement additions functions, and using a PLD to replace one than one glue logic IC. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713