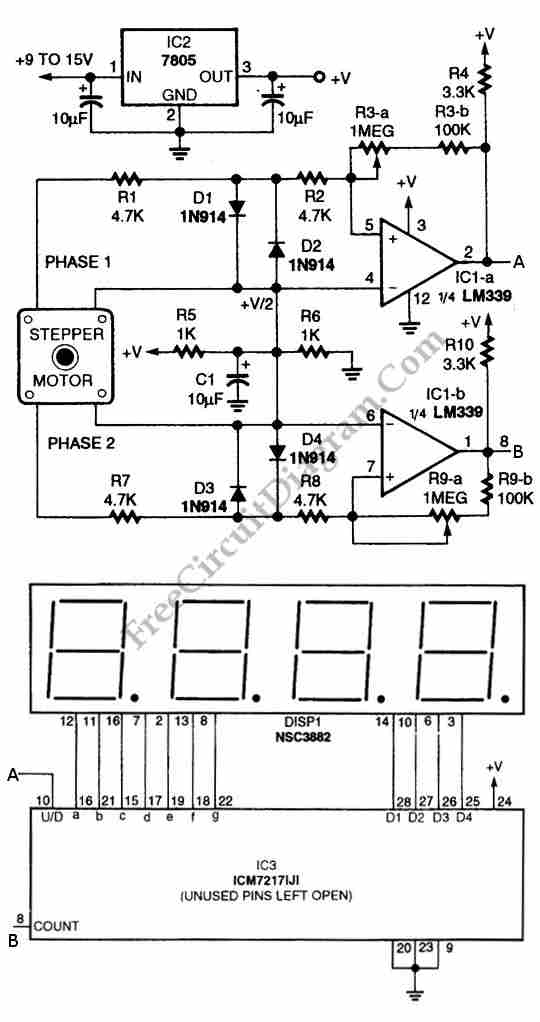

Digital Encoder Circuit Using Stepper Motor

The circuit illustrated in the schematic diagram below allows for the visualization of the direction and shaft rotation of a stepper motor on an LED display. Instead of employing a digital rotation encoder as an input, this circuit utilizes a stepper motor. Here is the schematic diagram of the circuit:

The circuit operates by utilizing a stepper motor, which is a type of motor that divides a full rotation into a number of equal steps. This allows for precise control of the motor's position and speed. The LED display serves as a visual output, indicating the current direction of rotation and the specific position of the motor shaft.

The schematic typically includes a microcontroller that processes input signals and determines the appropriate step sequence for the stepper motor. The microcontroller interfaces with the motor driver, which amplifies the control signals to drive the motor coils. The stepper motor is connected to the driver in a configuration that allows for full-step or half-step operation, depending on the desired resolution.

The LED display is connected to the microcontroller, which sends signals to illuminate specific segments of the display based on the motor's position and direction of rotation. This feedback mechanism is crucial for applications where precise motor control and real-time monitoring are necessary.

In summary, this circuit effectively combines a stepper motor with an LED display to provide a comprehensive solution for visualizing motor position and direction, replacing the need for more complex digital encoders while maintaining accuracy and reliability in motor control applications.Using circuit depicted in the schematic diagram below, the direction and shaft rotation of stepper motor can be seen on the LED display. Alternative to digital rotation encoder as a digital encoder input, this circuit uses a stepper motor.

Here is the schematic diagram of the circuit: 🔗 External reference

The circuit operates by utilizing a stepper motor, which is a type of motor that divides a full rotation into a number of equal steps. This allows for precise control of the motor's position and speed. The LED display serves as a visual output, indicating the current direction of rotation and the specific position of the motor shaft.

The schematic typically includes a microcontroller that processes input signals and determines the appropriate step sequence for the stepper motor. The microcontroller interfaces with the motor driver, which amplifies the control signals to drive the motor coils. The stepper motor is connected to the driver in a configuration that allows for full-step or half-step operation, depending on the desired resolution.

The LED display is connected to the microcontroller, which sends signals to illuminate specific segments of the display based on the motor's position and direction of rotation. This feedback mechanism is crucial for applications where precise motor control and real-time monitoring are necessary.

In summary, this circuit effectively combines a stepper motor with an LED display to provide a comprehensive solution for visualizing motor position and direction, replacing the need for more complex digital encoders while maintaining accuracy and reliability in motor control applications.Using circuit depicted in the schematic diagram below, the direction and shaft rotation of stepper motor can be seen on the LED display. Alternative to digital rotation encoder as a digital encoder input, this circuit uses a stepper motor.

Here is the schematic diagram of the circuit: 🔗 External reference