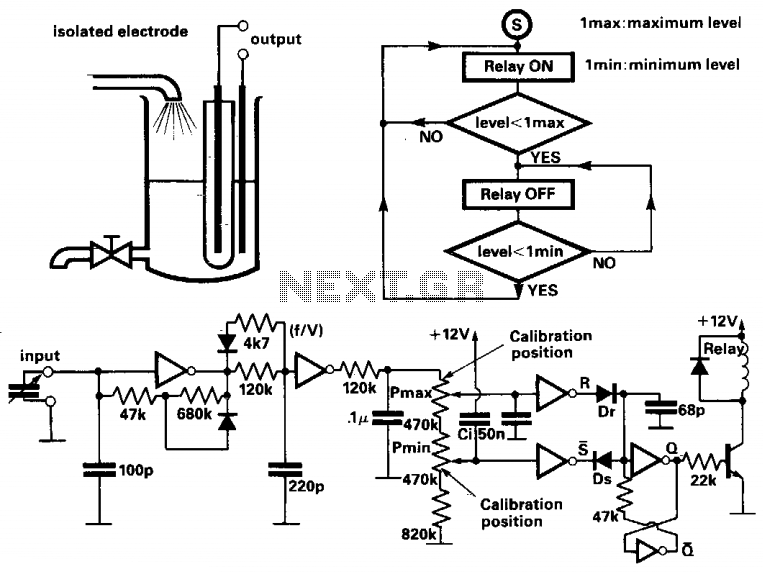

Single chip pump controller

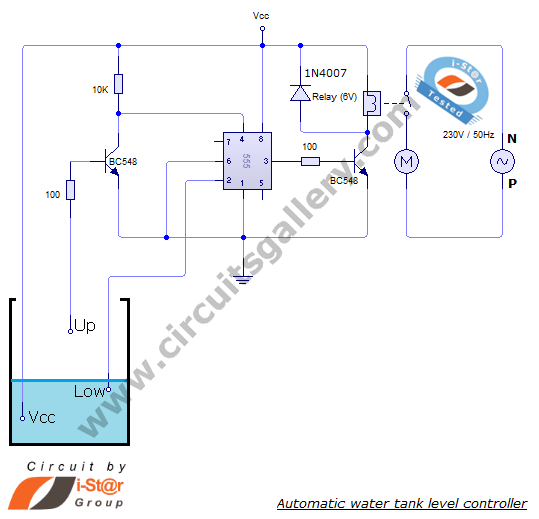

This circuit controls the liquid level in a tank using a bang-bang controlled electrical pump. The liquid level is measured by a capacitive level meter. The first inverter functions as a capacitance-to-frequency converter, operating as a Schmitt oscillator, where its frequency output decreases as the capacitance increases. The second inverter is a monostable device that acts as a frequency-to-voltage converter (f/V). Its output is connected to the inputs of maximum and minimum level comparators. The maximum and minimum liquid levels can be adjusted using potentiometers.

The maximum level (C1 max) can be set within the range of 65 pF to 120 pF, while the minimum level (C1 min) can be adjusted between 0 pF and 25 pF.

This circuit utilizes a bang-bang control mechanism, which is a type of on/off control system that provides rapid response to changes in the measured liquid level. The capacitive level meter detects the liquid level by measuring changes in capacitance caused by the presence of liquid in the tank. The first inverter, configured as a Schmitt oscillator, converts the capacitance measurement into a frequency signal. The frequency output is inversely proportional to the capacitance; thus, as the liquid level rises and capacitance increases, the output frequency decreases.

The second inverter operates as a monostable multivibrator, converting the frequency signal into a corresponding voltage level. This voltage level is then used to compare against preset thresholds for the maximum and minimum liquid levels, which are adjustable via potentiometers. The comparator circuits determine whether the liquid level is within the acceptable range and control the pump accordingly. If the level falls below the minimum threshold, the pump is activated to fill the tank, and if the level exceeds the maximum threshold, the pump is turned off.

The design allows for flexibility in setting the operational limits for the tank, ensuring that the liquid level is maintained within a specific range to prevent overflow or dry running of the pump. The use of capacitive sensing provides a non-contact method for level measurement, enhancing the reliability and longevity of the system.This circuit controls the level of a tank using a bang-bang controlled electrical pump. The actual level of liquid is measured by a capacitive level-meter. The first inverter performs as a capacitance to frequency converter. It is a Schmitt oscillator and its frequency output decreases as the capacitance increases. The second inverter is a monostable which performs as a frequency to voltage converter (f/V). Its output is applied to the maximum and minimum level comparator inputs. Maximum and minimum liquid levels may be set by the potentiometers. The maximum level (1 max) may be preset between the limits: 65 pF less than C (1 max) less than 120 pF. The minimum level is presetable and the limits are: 0 less than C (1 min) less than 25 pF. 🔗 External reference

The maximum level (C1 max) can be set within the range of 65 pF to 120 pF, while the minimum level (C1 min) can be adjusted between 0 pF and 25 pF.

This circuit utilizes a bang-bang control mechanism, which is a type of on/off control system that provides rapid response to changes in the measured liquid level. The capacitive level meter detects the liquid level by measuring changes in capacitance caused by the presence of liquid in the tank. The first inverter, configured as a Schmitt oscillator, converts the capacitance measurement into a frequency signal. The frequency output is inversely proportional to the capacitance; thus, as the liquid level rises and capacitance increases, the output frequency decreases.

The second inverter operates as a monostable multivibrator, converting the frequency signal into a corresponding voltage level. This voltage level is then used to compare against preset thresholds for the maximum and minimum liquid levels, which are adjustable via potentiometers. The comparator circuits determine whether the liquid level is within the acceptable range and control the pump accordingly. If the level falls below the minimum threshold, the pump is activated to fill the tank, and if the level exceeds the maximum threshold, the pump is turned off.

The design allows for flexibility in setting the operational limits for the tank, ensuring that the liquid level is maintained within a specific range to prevent overflow or dry running of the pump. The use of capacitive sensing provides a non-contact method for level measurement, enhancing the reliability and longevity of the system.This circuit controls the level of a tank using a bang-bang controlled electrical pump. The actual level of liquid is measured by a capacitive level-meter. The first inverter performs as a capacitance to frequency converter. It is a Schmitt oscillator and its frequency output decreases as the capacitance increases. The second inverter is a monostable which performs as a frequency to voltage converter (f/V). Its output is applied to the maximum and minimum level comparator inputs. Maximum and minimum liquid levels may be set by the potentiometers. The maximum level (1 max) may be preset between the limits: 65 pF less than C (1 max) less than 120 pF. The minimum level is presetable and the limits are: 0 less than C (1 min) less than 25 pF. 🔗 External reference