In-Cab Winch Controls and Winch Power Disconnect

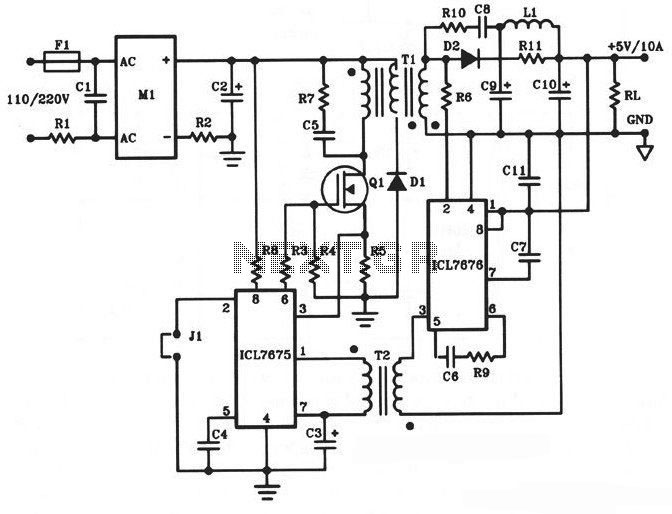

This project has been on the agenda for some time. The primary concern is that the winch on the Jeep is permanently connected to the battery, allowing unauthorized individuals in parking lots to potentially misuse the winch remote. To mitigate this risk, a power disconnect mechanism was desired to ensure the winch cannot be operated when not in use. Additionally, in case the winch solenoid becomes stuck, the ability to cut power serves as an emergency stop. Moreover, controlling the winch from inside the cab is more convenient, especially when assisting others with a winch pull. The power disconnect can be achieved using a relay or solenoid capable of handling the load. The winch's peak amperage draw varies by brand and type; for instance, a Superwinch is rated for a maximum current draw of 350 A at 9,000 lbs and 55 A at no load. To prevent potential hazards, such as a short circuit leading to battery failure or fire, a fuse rated at 500 A was added, despite 450 A being sufficient for the winch. The in-cab control includes a switch to actuate the relay supplying power to the winch, as well as a toggle switch for spooling the line in or out. To prevent simultaneous operation of the in-cab control and the remote pendant, circuitry was incorporated to disconnect the remote control when the in-cab switch is activated. The remote control plug consists of three wires, one providing 12 V and the others toggled by a switch for the spool-in and spool-out functions. A small 4 A fuse is included in this control line to protect against potential shorts, ensuring that any misuse does not compromise the more expensive 500 A fuse.

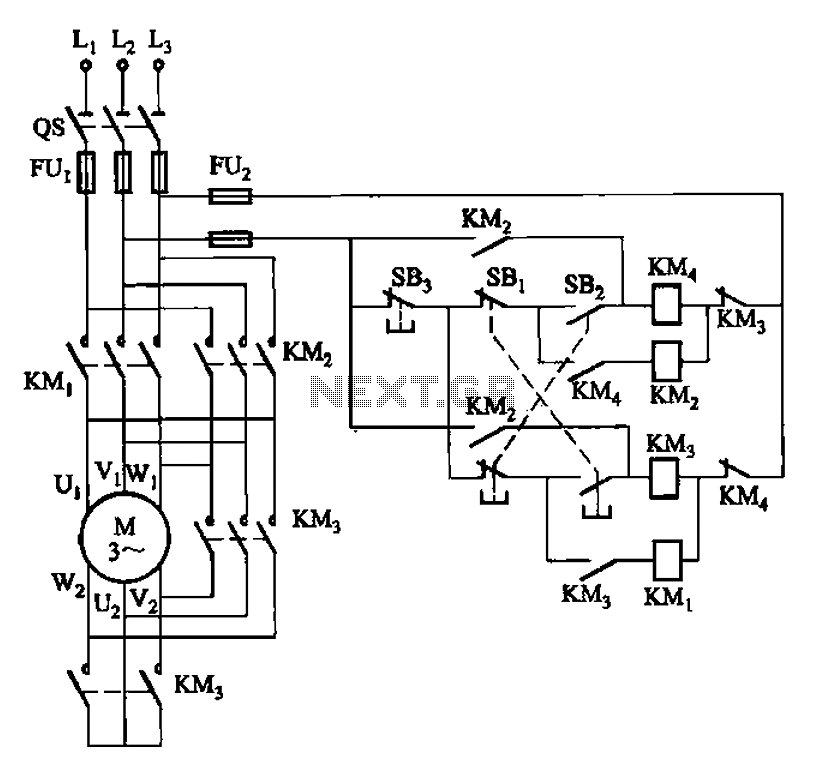

The dual-throw, dual-pole relay plays a crucial role in this circuit design. It is responsible for controlling the power flow to the winch motor based on the input from the cab switches. The relay must be rated for the maximum current draw of the winch to ensure reliable operation without overheating or failure. The relay's coil is activated by the in-cab switch, which closes the contacts and allows current to flow from the battery to the winch.

In terms of safety, the inclusion of a 500 A fuse in the main power line serves as a critical protection mechanism, preventing damage to the wiring and components in the event of a fault. Additionally, the 4 A fuse in the control circuit serves to protect the winch's control lines from accidental shorts, such as when a foreign object is inserted into the remote control port.

The design also considers the physical layout of the components. The relay should be mounted in a location that is easily accessible for maintenance but also protected from environmental factors such as moisture and dirt. Wires should be properly insulated and routed to prevent abrasion and accidental disconnection.

In summary, this winch control system enhances safety and usability by integrating an in-cab control mechanism, a power disconnect feature, and protective fuses, all while ensuring the system can handle the electrical demands of the winch. Proper attention to component ratings, wiring, and layout will contribute to a reliable and safe winching experience.This project was on my list for a while. The main reason was that the winch on the Jeep is permanently connected to the battery. So every nut job in a parking lot could just stick a paper clip into the winch remote and play with the winch, or worse, shorten it out. I wanted to disconnect power when the winch is not in use so no one can play with i t. The second reason is that, should the solenoid in the winch get suck somehow, the winch pull can be stopped by killing power, sorta like an Emergency Off button. I also wanted to control the winch from inside the cab. Most of the time when you winch other people out, you have to stay on the brakes anyway (unless you tied the Jeep up to, say, a tree or such).

So it`s just more convenient to have controls inside. The winch power disconnect was simple. All you need is a relay/solenoid big enough to handle the load. What peak Amperage the winch draws depends on the winch brand and type as well as the pull. More load/strain takes more power. Some winches use more power than others. I think my Superwinch was listed as having a 350 A max current draw at 9000 lbs (55 A at 0 lbs load). 350 A is a low draw compared to other winches, which was one reason I chose that winch. Other winches might be more around 450 A at full load. Since a short in the winch (motor melting or whatever) would mean shortening out the battery, and perhaps cause the power cable to catch fire, I thought it would be a good idea to add a fuse as well.

After all, most everything else in the Jeep is fused, so the winch should be as well. Again, I chose 500 A for the fuse (although 450 A would have been sufficient for my winch. But I`d rather not blow it out due to overload during a pull, and be left without a winch when I need it). Winch power will be controlled from the cab with a switch that actuates the relay that supplies power to the winch.

Also in the cab should be a toggle switch like the one on the winch remote pendant, to spool the line in or out. But what happens if someone is spooling in the line using the winch remote pendant, while someone else is pushing the spool-out switch inside the cab I wasn`t going to leave this "spool-in-and-out-at-the-same-time" problem until it happens to only then find out that the winch would explode in a huge fireball, or at least get damaged somehow.

So I added some circuitry that will disconnect the winch remote control pendant when the in-cab control is actuated. On the top left we see the "plug" of the remote control on the winch. The top right side is "what`s in the winch". The lines between them are normally connected. But we`ll add stuff in between so these lines will be "cut". When I checked out the remote control plug, I saw three wires. I quickly measured them and found one with 12 V. The other two are toggled with switch to provide 12 V power to the spool-in or spool-out lines of the main solenoid in the winch.

And since there really isn`t any electronics in the winch, it was obvious that this 12 V wasn`t fused either. When I measured current draw on the remote pendant, it was somewhere around 500 mA if I recall correctly.

That`s the current flowing into the main solenoid with will engage the contacts for switching power to the winch motor (and wound coil in case the winch doesn`t have a permanent magnet). *That* current is much higher or course (see above), but the control line only uses about 500 mA in my case.

So my drawing includes a small 4 A fuse on this link. That way, if someone does stick a paper clip in the winch control port, it doesn`t explode or shorten out the expensive 500 A fuse. Instead, it just blows a cheap 4 A fuse. Aside from this paper-clip silliness, remember that the winch control wires are run into the cab. So should those wires somewhere somehow shorten out, it`s best to just blow the quick, cheap 4 A fuse.

Let`s turn our attention to the dual-throw, dual-pole relay you see there 🔗 External reference

The dual-throw, dual-pole relay plays a crucial role in this circuit design. It is responsible for controlling the power flow to the winch motor based on the input from the cab switches. The relay must be rated for the maximum current draw of the winch to ensure reliable operation without overheating or failure. The relay's coil is activated by the in-cab switch, which closes the contacts and allows current to flow from the battery to the winch.

In terms of safety, the inclusion of a 500 A fuse in the main power line serves as a critical protection mechanism, preventing damage to the wiring and components in the event of a fault. Additionally, the 4 A fuse in the control circuit serves to protect the winch's control lines from accidental shorts, such as when a foreign object is inserted into the remote control port.

The design also considers the physical layout of the components. The relay should be mounted in a location that is easily accessible for maintenance but also protected from environmental factors such as moisture and dirt. Wires should be properly insulated and routed to prevent abrasion and accidental disconnection.

In summary, this winch control system enhances safety and usability by integrating an in-cab control mechanism, a power disconnect feature, and protective fuses, all while ensuring the system can handle the electrical demands of the winch. Proper attention to component ratings, wiring, and layout will contribute to a reliable and safe winching experience.This project was on my list for a while. The main reason was that the winch on the Jeep is permanently connected to the battery. So every nut job in a parking lot could just stick a paper clip into the winch remote and play with the winch, or worse, shorten it out. I wanted to disconnect power when the winch is not in use so no one can play with i t. The second reason is that, should the solenoid in the winch get suck somehow, the winch pull can be stopped by killing power, sorta like an Emergency Off button. I also wanted to control the winch from inside the cab. Most of the time when you winch other people out, you have to stay on the brakes anyway (unless you tied the Jeep up to, say, a tree or such).

So it`s just more convenient to have controls inside. The winch power disconnect was simple. All you need is a relay/solenoid big enough to handle the load. What peak Amperage the winch draws depends on the winch brand and type as well as the pull. More load/strain takes more power. Some winches use more power than others. I think my Superwinch was listed as having a 350 A max current draw at 9000 lbs (55 A at 0 lbs load). 350 A is a low draw compared to other winches, which was one reason I chose that winch. Other winches might be more around 450 A at full load. Since a short in the winch (motor melting or whatever) would mean shortening out the battery, and perhaps cause the power cable to catch fire, I thought it would be a good idea to add a fuse as well.

After all, most everything else in the Jeep is fused, so the winch should be as well. Again, I chose 500 A for the fuse (although 450 A would have been sufficient for my winch. But I`d rather not blow it out due to overload during a pull, and be left without a winch when I need it). Winch power will be controlled from the cab with a switch that actuates the relay that supplies power to the winch.

Also in the cab should be a toggle switch like the one on the winch remote pendant, to spool the line in or out. But what happens if someone is spooling in the line using the winch remote pendant, while someone else is pushing the spool-out switch inside the cab I wasn`t going to leave this "spool-in-and-out-at-the-same-time" problem until it happens to only then find out that the winch would explode in a huge fireball, or at least get damaged somehow.

So I added some circuitry that will disconnect the winch remote control pendant when the in-cab control is actuated. On the top left we see the "plug" of the remote control on the winch. The top right side is "what`s in the winch". The lines between them are normally connected. But we`ll add stuff in between so these lines will be "cut". When I checked out the remote control plug, I saw three wires. I quickly measured them and found one with 12 V. The other two are toggled with switch to provide 12 V power to the spool-in or spool-out lines of the main solenoid in the winch.

And since there really isn`t any electronics in the winch, it was obvious that this 12 V wasn`t fused either. When I measured current draw on the remote pendant, it was somewhere around 500 mA if I recall correctly.

That`s the current flowing into the main solenoid with will engage the contacts for switching power to the winch motor (and wound coil in case the winch doesn`t have a permanent magnet). *That* current is much higher or course (see above), but the control line only uses about 500 mA in my case.

So my drawing includes a small 4 A fuse on this link. That way, if someone does stick a paper clip in the winch control port, it doesn`t explode or shorten out the expensive 500 A fuse. Instead, it just blows a cheap 4 A fuse. Aside from this paper-clip silliness, remember that the winch control wires are run into the cab. So should those wires somewhere somehow shorten out, it`s best to just blow the quick, cheap 4 A fuse.

Let`s turn our attention to the dual-throw, dual-pole relay you see there 🔗 External reference