Instrument panel lamp dimmer control Circuit

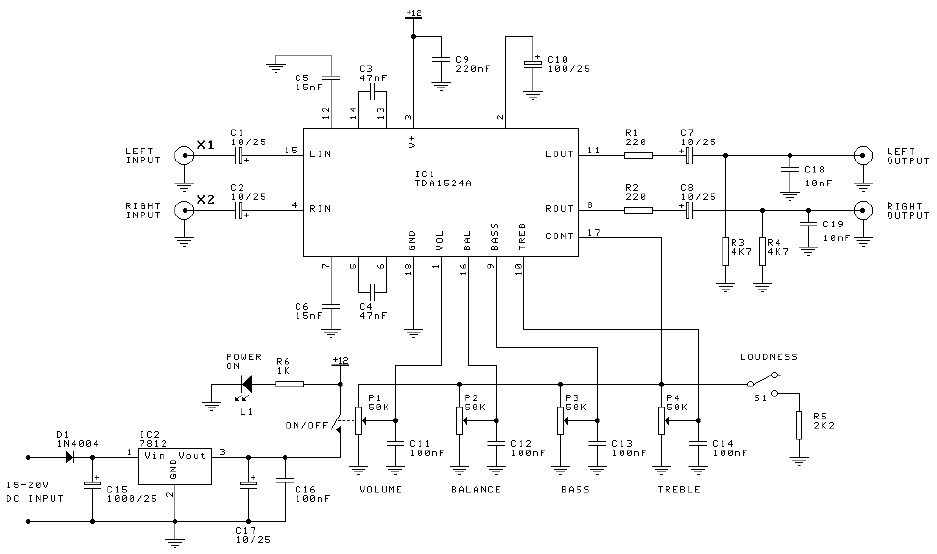

This circuit utilizes an MC3392 low-side protected switch in conjunction with an MC1455 timing circuit to create a dimmer control for automotive instrumentation panel lamps. The brightness of incandescent lamps is adjustable through Pulse Width Modulation (PWM) applied to the MC3392's input. The PWM signal can be sourced directly from the MC1455 timer or a microprocessor. The MC1455 is configured as a free-running clock with adjustable frequency and duty cycle. The typical operating frequency is around 80 Hz when the frequency potentiometer is set to 1.0 kΩ, a value selected to prevent noticeable lamp flicker. The duty cycle can be varied from approximately 3% to 97% using a potentiometer, where 3% results in the lamps being nearly off and 97% results in them being nearly fully on. This circuit can control multiple lamps, provided that the total load current does not exceed 1 amp. An LED indicator is included to signal any system faults, such as overvoltage, current limiting, or thermal shutdown.

The circuit design employs the MC3392 as a low-side switch, which provides a safe method for controlling the power to the lamps. The low-side switching configuration allows for simpler control of the load and helps in managing the heat dissipation effectively. The MC1455 timer serves as the core of the PWM signal generation. By configuring the MC1455 in astable mode, it produces a continuous square wave output, the frequency of which can be adjusted by varying the resistance of the connected potentiometer.

The output frequency of approximately 80 Hz is optimal for automotive applications, as it minimizes the perception of flickering by the human eye, ensuring a smooth and consistent illumination of the panel lamps. The duty cycle adjustment allows for fine-tuning of the lamp brightness, catering to user preferences or specific requirements of the vehicle's instrumentation.

The circuit's design also includes a current limiting feature, ensuring that the total load does not exceed 1 amp, which is crucial for maintaining the integrity of the components and preventing potential damage. The inclusion of an LED indicator enhances the functionality of the circuit by providing visual feedback in the event of a fault condition, allowing for quick diagnosis and troubleshooting. This comprehensive approach to automotive lamp dimming not only enhances user experience but also contributes to the overall safety and reliability of the vehicle's electrical system.This circuit uses an MC3392 low side protected switch and an MC1455 timing circuit to form an automotive instrumentation panel lamp dimmer control. The brightness of incandescent lamps can be varied by Pulse Width Modulating the input of the MC3392.

The modulating signal can be obtained directly from the MC1455 timer (or a microprocessor). The MC1 455 is configured as a free-running clock having a frequency and duty cycle control. The typical timer frequency is approximately 80 Hz when the frequency potentiometer is adjusted to 1. 0k. This frequency was chosen so as to avoid any perceptible lamp flicker. The duty cycle potentiometer controls the duty cycle over a range of about 3% to 97%. When at 3% the lamps are essentialy off, at 97% the lamps are essentially full on. Any number of lamps can be control, so long as the total load current is less than 1 amp. The LED is used to signal the existence of a system fault (overvoltage, current limiting, or thermal shutdown).

🔗 External reference

The circuit design employs the MC3392 as a low-side switch, which provides a safe method for controlling the power to the lamps. The low-side switching configuration allows for simpler control of the load and helps in managing the heat dissipation effectively. The MC1455 timer serves as the core of the PWM signal generation. By configuring the MC1455 in astable mode, it produces a continuous square wave output, the frequency of which can be adjusted by varying the resistance of the connected potentiometer.

The output frequency of approximately 80 Hz is optimal for automotive applications, as it minimizes the perception of flickering by the human eye, ensuring a smooth and consistent illumination of the panel lamps. The duty cycle adjustment allows for fine-tuning of the lamp brightness, catering to user preferences or specific requirements of the vehicle's instrumentation.

The circuit's design also includes a current limiting feature, ensuring that the total load does not exceed 1 amp, which is crucial for maintaining the integrity of the components and preventing potential damage. The inclusion of an LED indicator enhances the functionality of the circuit by providing visual feedback in the event of a fault condition, allowing for quick diagnosis and troubleshooting. This comprehensive approach to automotive lamp dimming not only enhances user experience but also contributes to the overall safety and reliability of the vehicle's electrical system.This circuit uses an MC3392 low side protected switch and an MC1455 timing circuit to form an automotive instrumentation panel lamp dimmer control. The brightness of incandescent lamps can be varied by Pulse Width Modulating the input of the MC3392.

The modulating signal can be obtained directly from the MC1455 timer (or a microprocessor). The MC1 455 is configured as a free-running clock having a frequency and duty cycle control. The typical timer frequency is approximately 80 Hz when the frequency potentiometer is adjusted to 1. 0k. This frequency was chosen so as to avoid any perceptible lamp flicker. The duty cycle potentiometer controls the duty cycle over a range of about 3% to 97%. When at 3% the lamps are essentialy off, at 97% the lamps are essentially full on. Any number of lamps can be control, so long as the total load current is less than 1 amp. The LED is used to signal the existence of a system fault (overvoltage, current limiting, or thermal shutdown).

🔗 External reference