Invert a 555 Astable Output Signal

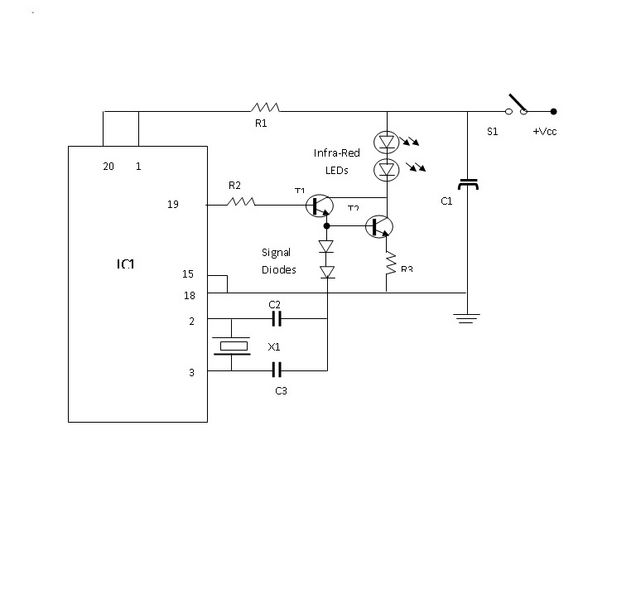

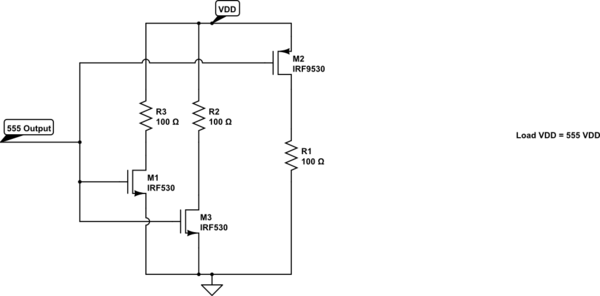

A variable frequency, variably duty cycle 555 configuration is set up in astable mode. A set of potentiometers is utilized to achieve a wide range of control. The output is functioning well; however, there is an issue. The circuit drives a couple of MOSFETs directly from the output, but there is a need for a third MOSFET that operates inversely to the timing of the first two. For instance, when running at a 25% duty cycle, the first two MOSFETs are ON for 25% of the cycle while the third one is OFF during that time, and then the states are reversed for the OFF period of the cycle. Some diagrams suggest using an additional MOSFET or transistor with a resistor to invert the signal, but this method results in slow rise and fall times. The goal is to achieve a nearly perfect inversion of the square signal. The third MOSFET must turn ON precisely when the first two turn OFF, and accurate timing is crucial without introducing overly complex circuitry. The circuit should not exceed two or three 555 timers or additional transistors for signal inversion. It has been noted that a 555 timer can function as a 200mA signal inverter, which is advantageous given that this current level is significantly higher than that of typical logic unit inverters, which usually have a maximum output of 10 or 20mA.

To implement the described functionality, a 555 timer can be configured to serve as an inverter in conjunction with the existing astable configuration. The primary 555 timer produces a square wave output that controls the two MOSFETs. The secondary 555 timer, configured in monostable mode, can be triggered by the falling edge of the output from the first timer. This configuration allows for precise timing control, ensuring that the third MOSFET turns ON immediately as the first two turn OFF.

The setup involves connecting the output of the first 555 timer to the trigger input of the second 555 timer. A capacitor can be placed between the output of the first timer and the trigger pin of the second timer to ensure that the second timer is triggered by the falling edge of the signal, creating a sharp transition. The second timer can be adjusted to have a short pulse width, which will drive the third MOSFET ON for the duration that the first two are OFF.

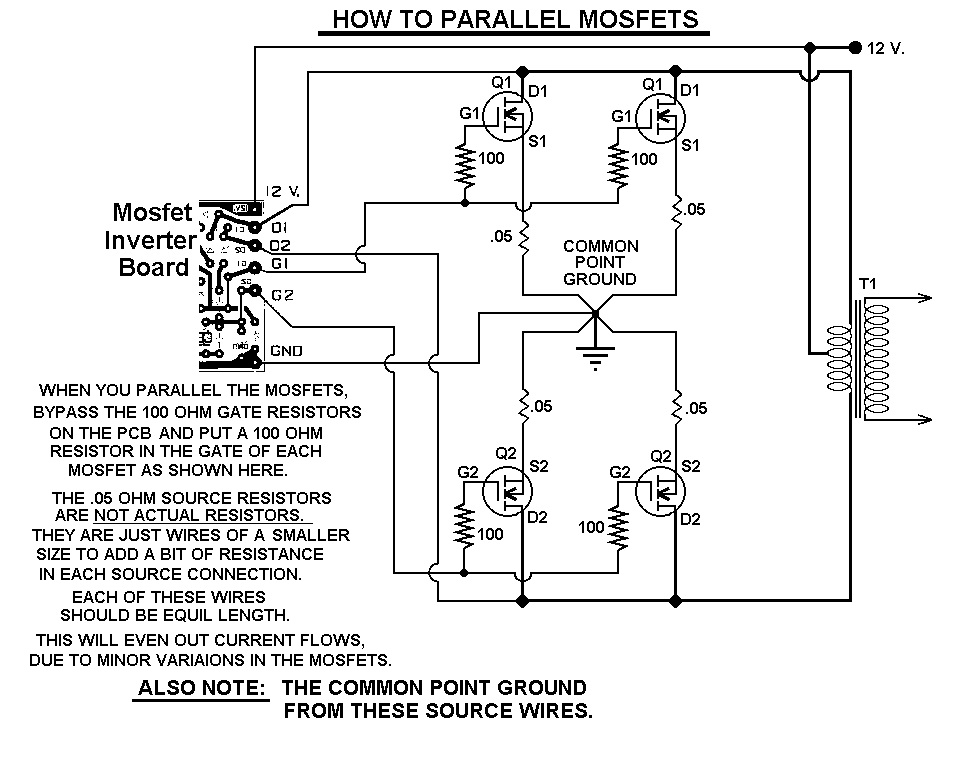

For the MOSFETs, it is essential to select devices that can handle the required load and switching speeds. The gate drive circuit for the MOSFETs should be designed to provide sufficient drive current to ensure fast switching. This can be achieved by using gate resistors that are low enough to allow for quick charging and discharging of the gate capacitance, thereby minimizing rise and fall times.

Overall, this approach maintains simplicity while achieving the desired control over the MOSFETs, ensuring that the output characteristics meet the specified requirements without introducing excessive complexity into the circuit design.A variable frequency, variably duty cycle 555 configuration in astable mode. I`m using a set of pots to get a wide range of control. It works beautifully. The output is great, but I have a problem. I am driving a couple mosfets directly from the output. But I want to have a third mosfet that turns on and off opposite to the timing of the first two. So if I`m running 25% duty cycle, the first two are ON for 25% of the cycle while the third one is OFF during that portion and then reverse this for the OFF period of the cycle. I`ve seen some diagrams that talk about using one extra mosfet or one extra transistor along with a resistor to invert a signal, but they don`t create hard/fast rise and fall times.

The resistor causes slow rise times. I want a nearly perfect inversion of the square signal. Right at the moment that the first two mosfets flip off, the third mosfet needs to flip full on. It`s critical that I get this to be as accurate as is feasible without getting into overly complex circuitry. Anything more than two or three 555s and/or two or three extra transistors (possibly needed to invert the signal) is more than I`m bargaining for.

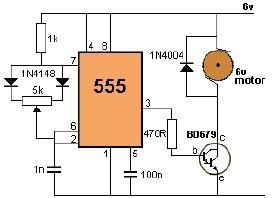

I`m not posting this as an answer yet, because I`m waiting to hear a response from the other answerer. But apaprently you can run a 555 as a 200mA signal inverter. This is really simple for a person who already has 555s on hand, and the best part is that the 200mA current is WAY higher than a typical logic unit inverter (often topping out at least than 10 or 20mA).

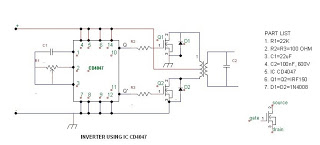

Here`s a page with a circuit at the bottom explaining Inverter mode: 🔗 External reference

To implement the described functionality, a 555 timer can be configured to serve as an inverter in conjunction with the existing astable configuration. The primary 555 timer produces a square wave output that controls the two MOSFETs. The secondary 555 timer, configured in monostable mode, can be triggered by the falling edge of the output from the first timer. This configuration allows for precise timing control, ensuring that the third MOSFET turns ON immediately as the first two turn OFF.

The setup involves connecting the output of the first 555 timer to the trigger input of the second 555 timer. A capacitor can be placed between the output of the first timer and the trigger pin of the second timer to ensure that the second timer is triggered by the falling edge of the signal, creating a sharp transition. The second timer can be adjusted to have a short pulse width, which will drive the third MOSFET ON for the duration that the first two are OFF.

For the MOSFETs, it is essential to select devices that can handle the required load and switching speeds. The gate drive circuit for the MOSFETs should be designed to provide sufficient drive current to ensure fast switching. This can be achieved by using gate resistors that are low enough to allow for quick charging and discharging of the gate capacitance, thereby minimizing rise and fall times.

Overall, this approach maintains simplicity while achieving the desired control over the MOSFETs, ensuring that the output characteristics meet the specified requirements without introducing excessive complexity into the circuit design.A variable frequency, variably duty cycle 555 configuration in astable mode. I`m using a set of pots to get a wide range of control. It works beautifully. The output is great, but I have a problem. I am driving a couple mosfets directly from the output. But I want to have a third mosfet that turns on and off opposite to the timing of the first two. So if I`m running 25% duty cycle, the first two are ON for 25% of the cycle while the third one is OFF during that portion and then reverse this for the OFF period of the cycle. I`ve seen some diagrams that talk about using one extra mosfet or one extra transistor along with a resistor to invert a signal, but they don`t create hard/fast rise and fall times.

The resistor causes slow rise times. I want a nearly perfect inversion of the square signal. Right at the moment that the first two mosfets flip off, the third mosfet needs to flip full on. It`s critical that I get this to be as accurate as is feasible without getting into overly complex circuitry. Anything more than two or three 555s and/or two or three extra transistors (possibly needed to invert the signal) is more than I`m bargaining for.

I`m not posting this as an answer yet, because I`m waiting to hear a response from the other answerer. But apaprently you can run a 555 as a 200mA signal inverter. This is really simple for a person who already has 555s on hand, and the best part is that the 200mA current is WAY higher than a typical logic unit inverter (often topping out at least than 10 or 20mA).

Here`s a page with a circuit at the bottom explaining Inverter mode: 🔗 External reference