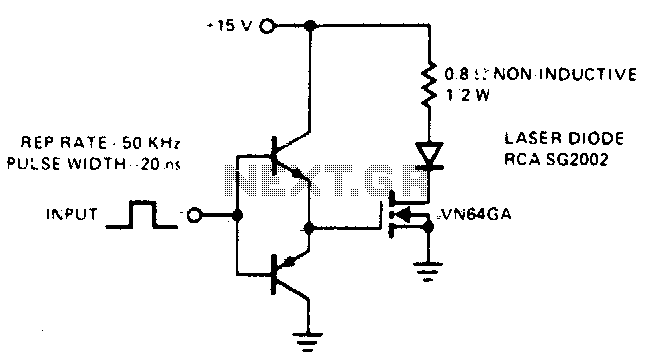

Laser diode pulser

This drive is capable of supplying the laser diode with 10 ampere pulses lasting 20 ns. With a 0% duty cycle, the repetition rate is 50 kHz. A complementary emitter-follower configuration is utilized as a driver. Switching speed is influenced by the frequency response of the bipolar transistors employed and the impedance of the drive source.

The described drive circuit is designed to control a laser diode effectively, delivering high current pulses essential for applications requiring rapid on-off switching. The capability to provide 10 amperes of current in 20 ns pulses indicates a robust design suitable for high-power laser applications, such as in industrial cutting or medical devices.

The complementary emitter-follower configuration enhances the drive capability by providing high current gain while maintaining a low output impedance. This configuration allows the circuit to drive the laser diode efficiently, ensuring that the diode receives the necessary current without significant voltage drop across the driver stage.

The specification of a 0% duty cycle at a 50 kHz repetition rate suggests that the laser operates in a pulsed mode, which is critical for preventing overheating and extending the lifespan of the diode. The drive circuit's ability to achieve this high frequency is contingent upon the switching speed of the bipolar transistors used. The frequency response of these transistors must be optimized to minimize delays and ensure that the pulses are delivered accurately and consistently.

Additionally, the impedance of the drive source plays a crucial role in the overall performance of the circuit. A lower impedance can enhance the speed of the current rise and fall times, thus improving the overall efficiency of the drive. Careful selection of components, including the transistors and associated passive elements, is essential to achieve the desired performance metrics.

In summary, the drive circuit's design allows for effective control of a laser diode through high-speed pulsing, ensuring that it meets the rigorous demands of various applications while maintaining reliability and efficiency.This drive is capable of driving the laser diode with 10 ampere, 20 ns pulses. For a 0% duty cycle, the repetition rate will be 50 kHz. A complementary emitter-follower is used as a driver Switching speed is determined by the fr of the bipolar transistors used and the impedance of the drive source.

The described drive circuit is designed to control a laser diode effectively, delivering high current pulses essential for applications requiring rapid on-off switching. The capability to provide 10 amperes of current in 20 ns pulses indicates a robust design suitable for high-power laser applications, such as in industrial cutting or medical devices.

The complementary emitter-follower configuration enhances the drive capability by providing high current gain while maintaining a low output impedance. This configuration allows the circuit to drive the laser diode efficiently, ensuring that the diode receives the necessary current without significant voltage drop across the driver stage.

The specification of a 0% duty cycle at a 50 kHz repetition rate suggests that the laser operates in a pulsed mode, which is critical for preventing overheating and extending the lifespan of the diode. The drive circuit's ability to achieve this high frequency is contingent upon the switching speed of the bipolar transistors used. The frequency response of these transistors must be optimized to minimize delays and ensure that the pulses are delivered accurately and consistently.

Additionally, the impedance of the drive source plays a crucial role in the overall performance of the circuit. A lower impedance can enhance the speed of the current rise and fall times, thus improving the overall efficiency of the drive. Careful selection of components, including the transistors and associated passive elements, is essential to achieve the desired performance metrics.

In summary, the drive circuit's design allows for effective control of a laser diode through high-speed pulsing, ensuring that it meets the rigorous demands of various applications while maintaining reliability and efficiency.This drive is capable of driving the laser diode with 10 ampere, 20 ns pulses. For a 0% duty cycle, the repetition rate will be 50 kHz. A complementary emitter-follower is used as a driver Switching speed is determined by the fr of the bipolar transistors used and the impedance of the drive source.