Stabilizing a laser discharge current

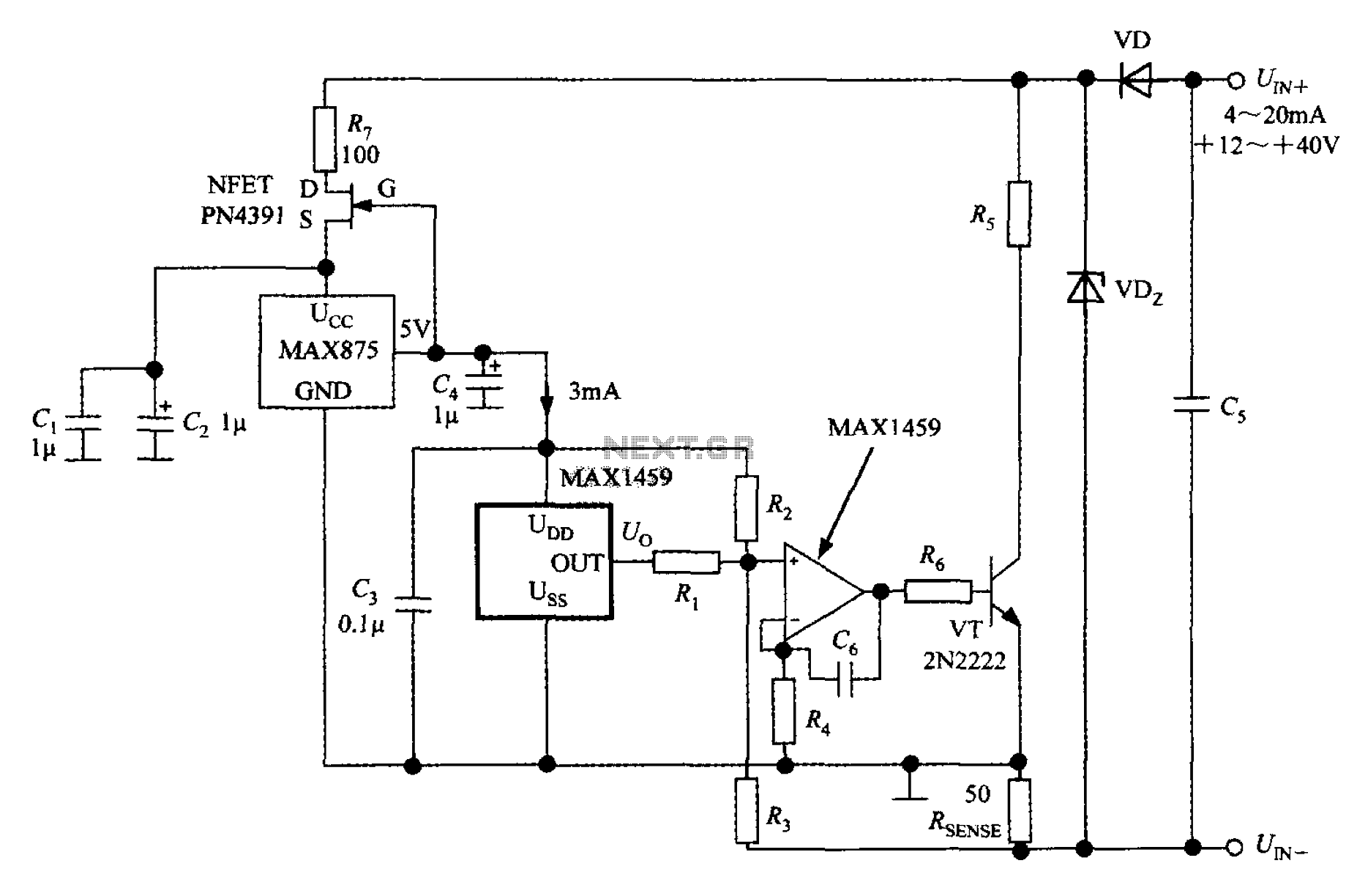

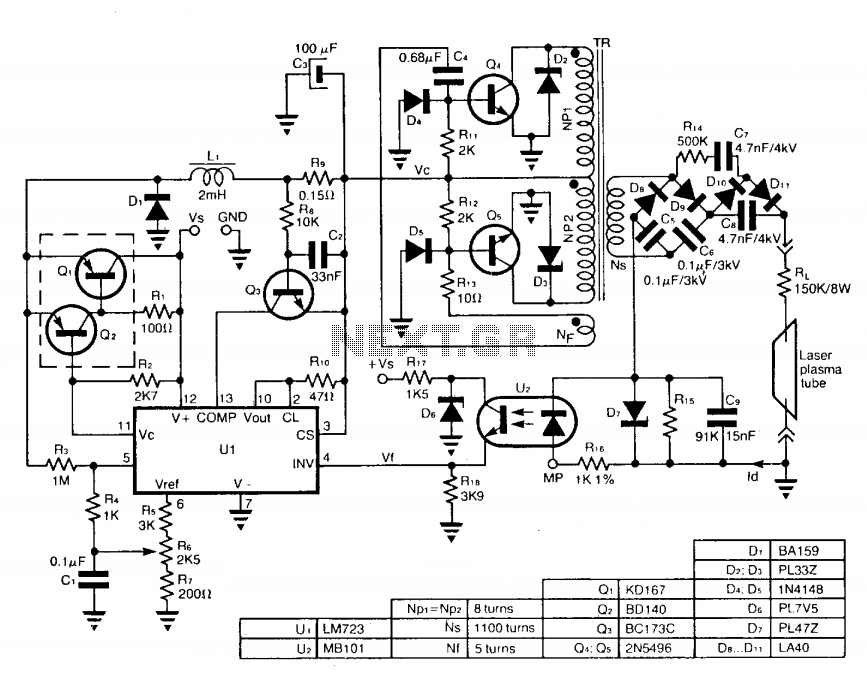

The circuit employs a free-running push-pull DC to DC high voltage converter to generate the required voltage for the laser plasma tube supply. The supply voltage (Vc) of this converter is regulated by a switch-mode power supply to maintain a constant load current at a predetermined value. A linear opto-electronic isolator (U2), connected in series with the laser plasma tube, provides a voltage (Vp) that is proportional to the discharge current (ID) across resistor R18, ensuring the correct polarity to directly drive the inverting input of operational amplifier U1. Diode D7 and resistor R15 are included to protect the optoisolator diode from damage caused by the high-voltage ignition pulse.

Due to the high operating frequency of the high voltage converter (25 kHz), the ripple in the laser output power is less than 2 x 10^-4. The stability of the discharge current (ID) is better than 10^-2 for variations in supply voltage (Vs) within a range of ±10%, and it is influenced by the sensitivity of the optoisolator.

The circuit design incorporates a free-running push-pull configuration for the DC to DC high voltage converter, which is essential for generating the high voltage necessary for the laser plasma tube. The switch-mode power supply plays a critical role in adjusting the supply voltage (Vc) to ensure that the load current remains stable, which is crucial for consistent laser performance.

The opto-electronic isolator (U2) serves to provide electrical isolation between the high voltage components and the control circuitry. By measuring the discharge current (ID) across resistor R18, the circuit can accurately monitor the performance of the laser plasma tube. The proportional voltage (Vp) generated by the optoisolator allows for precise control of the operational amplifier (U1), which in turn regulates the output based on the feedback received from the opto-isolator.

Protection components such as diode D7 and resistor R15 are strategically placed to safeguard the optoisolator from potential damage due to high-voltage spikes during the ignition process, ensuring the longevity and reliability of the circuit.

The high operating frequency of 25 kHz minimizes the ripple in the output power of the laser, which is critical for applications requiring stable and consistent performance. The circuit's ability to maintain a discharge current stability of better than 10^-2 under varying supply voltage conditions indicates a robust design that can accommodate fluctuations in input power while still delivering reliable output. The sensitivity of the optoisolator further enhances the circuit's performance, allowing for fine-tuning and adjustments as necessary to maintain optimal operation of the laser plasma tube.The circuit uses a free-running push-pull dc to dc high voltage converter to get the necessary voltage for the laser plasma tube supply. The supply voltage Vc of this converter, is adjusted by a switch-mode power supply in order to keep the load current constant, at set value.

The linear opto-electronic isolator U2, connected in series with the laser plasma tube, gives a voltage Vp proportional to the discharge current ID across R18, having the correct polarity to drive directly the inverting input of Ul, D7, R15 protects the optoisolator diode against damage produced by the high voltage ignition pulse. Due to the high operating frequency of the high voltage converter (25 kHz) the ripple of the laser output power is less than 2.10~4. The stability of ID is better than 10~2, for variations of supply voltage Vs is the range of ± 10%, and depends on the optoisolator sensitivity.

🔗 External reference

Due to the high operating frequency of the high voltage converter (25 kHz), the ripple in the laser output power is less than 2 x 10^-4. The stability of the discharge current (ID) is better than 10^-2 for variations in supply voltage (Vs) within a range of ±10%, and it is influenced by the sensitivity of the optoisolator.

The circuit design incorporates a free-running push-pull configuration for the DC to DC high voltage converter, which is essential for generating the high voltage necessary for the laser plasma tube. The switch-mode power supply plays a critical role in adjusting the supply voltage (Vc) to ensure that the load current remains stable, which is crucial for consistent laser performance.

The opto-electronic isolator (U2) serves to provide electrical isolation between the high voltage components and the control circuitry. By measuring the discharge current (ID) across resistor R18, the circuit can accurately monitor the performance of the laser plasma tube. The proportional voltage (Vp) generated by the optoisolator allows for precise control of the operational amplifier (U1), which in turn regulates the output based on the feedback received from the opto-isolator.

Protection components such as diode D7 and resistor R15 are strategically placed to safeguard the optoisolator from potential damage due to high-voltage spikes during the ignition process, ensuring the longevity and reliability of the circuit.

The high operating frequency of 25 kHz minimizes the ripple in the output power of the laser, which is critical for applications requiring stable and consistent performance. The circuit's ability to maintain a discharge current stability of better than 10^-2 under varying supply voltage conditions indicates a robust design that can accommodate fluctuations in input power while still delivering reliable output. The sensitivity of the optoisolator further enhances the circuit's performance, allowing for fine-tuning and adjustments as necessary to maintain optimal operation of the laser plasma tube.The circuit uses a free-running push-pull dc to dc high voltage converter to get the necessary voltage for the laser plasma tube supply. The supply voltage Vc of this converter, is adjusted by a switch-mode power supply in order to keep the load current constant, at set value.

The linear opto-electronic isolator U2, connected in series with the laser plasma tube, gives a voltage Vp proportional to the discharge current ID across R18, having the correct polarity to drive directly the inverting input of Ul, D7, R15 protects the optoisolator diode against damage produced by the high voltage ignition pulse. Due to the high operating frequency of the high voltage converter (25 kHz) the ripple of the laser output power is less than 2.10~4. The stability of ID is better than 10~2, for variations of supply voltage Vs is the range of ± 10%, and depends on the optoisolator sensitivity.

🔗 External reference