laser jammers

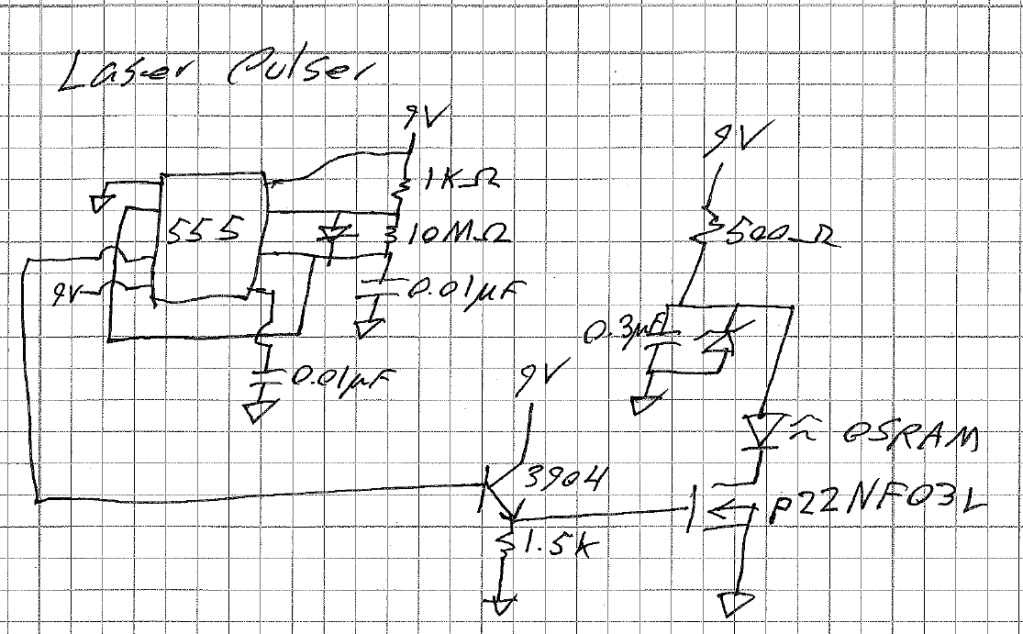

A laser pulser utilizing the same laser diode LI. The pulser is adjustable from 50 to 20,000 ppm. Tests conducted on LI and RX65 indicate that they only respond to pulses ranging from approximately 100 to 200 ppm. There is also curiosity regarding the potential of the pulser to function as a jammer if the frequency is maximized, similar to an effective brute force jammer.

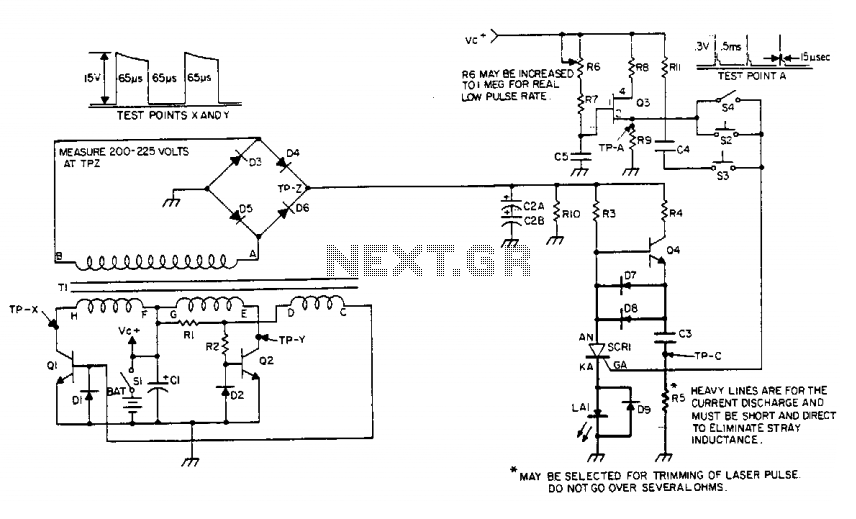

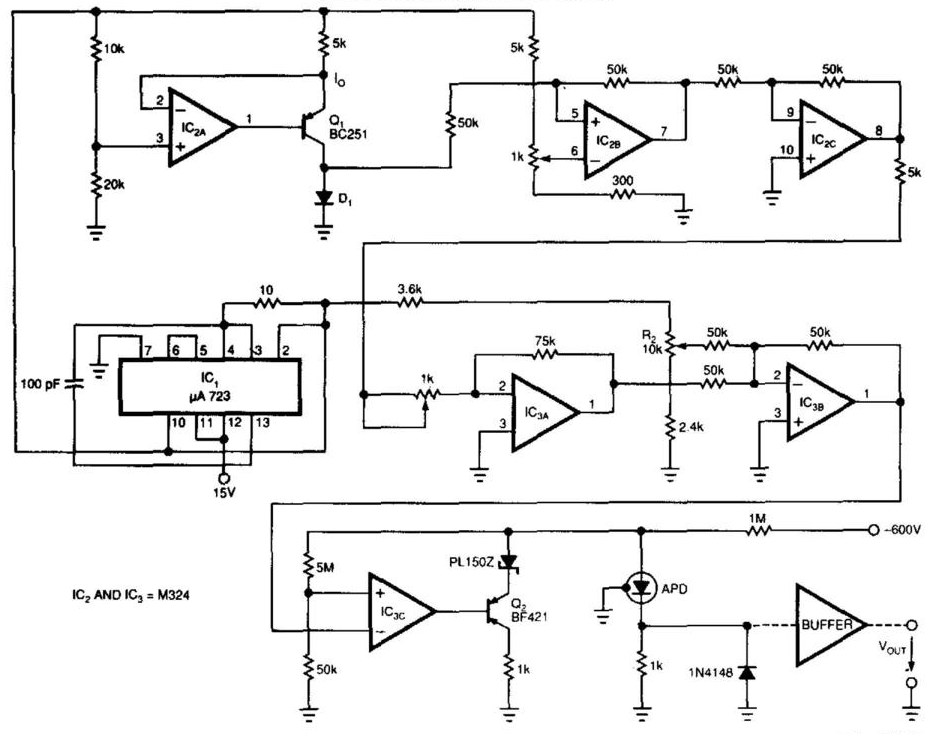

The laser pulser described operates by modulating the output of a laser diode, specifically the LI model. The adjustable range of 50 to 20,000 parts per million (ppm) allows for versatile applications, including precise control over the intensity and frequency of the emitted laser pulses. The design includes a variable resistor or digital control circuitry that permits the user to easily set the desired ppm level.

In testing, the pulser has been found to effectively trigger the LI and RX65 devices at pulse frequencies between 100 and 200 ppm. This limited response range suggests that the pulser's output characteristics align closely with the detection capabilities of these devices. The pulser may utilize a pulse-width modulation (PWM) technique to vary the laser's output, ensuring that the pulses remain within the operational parameters of the target devices.

The concept of using the pulser as a jammer is intriguing. If the frequency is increased beyond the tested range, it may overwhelm the sensors of nearby devices, potentially disrupting their normal operation. This would mimic the function of traditional brute force jammers, which operate by emitting signals at frequencies that interfere with the reception of legitimate signals.

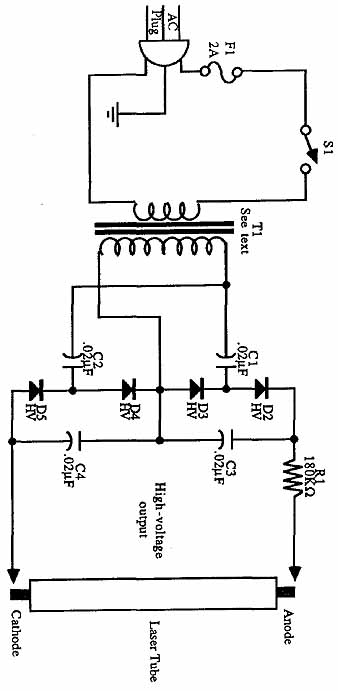

In terms of circuit design, the pulser may incorporate a microcontroller to manage the pulse generation and frequency adjustments. Additional components such as capacitors, resistors, and possibly a feedback loop could be included to stabilize the output and ensure consistent performance across the specified range. Power supply considerations should also be addressed, as the laser diode requires a stable voltage and current to operate effectively without overheating or damaging the component.

Overall, the laser pulser presents a flexible solution for applications requiring precise laser modulation, with potential implications for signal interference in electronic communications.A laser pulser using the same laser diode LI does. I made the pulser so it could be adjusted from 50 to 20, 000ppm. I tested that on my LIs and rx65, they only alert to pulses from about 100 to 200ppm. I also wonder if my pulsure would work as a jammer if I turned the frequency all the way up, sort of like an old brute force jammer that worked really well. 🔗 External reference

The laser pulser described operates by modulating the output of a laser diode, specifically the LI model. The adjustable range of 50 to 20,000 parts per million (ppm) allows for versatile applications, including precise control over the intensity and frequency of the emitted laser pulses. The design includes a variable resistor or digital control circuitry that permits the user to easily set the desired ppm level.

In testing, the pulser has been found to effectively trigger the LI and RX65 devices at pulse frequencies between 100 and 200 ppm. This limited response range suggests that the pulser's output characteristics align closely with the detection capabilities of these devices. The pulser may utilize a pulse-width modulation (PWM) technique to vary the laser's output, ensuring that the pulses remain within the operational parameters of the target devices.

The concept of using the pulser as a jammer is intriguing. If the frequency is increased beyond the tested range, it may overwhelm the sensors of nearby devices, potentially disrupting their normal operation. This would mimic the function of traditional brute force jammers, which operate by emitting signals at frequencies that interfere with the reception of legitimate signals.

In terms of circuit design, the pulser may incorporate a microcontroller to manage the pulse generation and frequency adjustments. Additional components such as capacitors, resistors, and possibly a feedback loop could be included to stabilize the output and ensure consistent performance across the specified range. Power supply considerations should also be addressed, as the laser diode requires a stable voltage and current to operate effectively without overheating or damaging the component.

Overall, the laser pulser presents a flexible solution for applications requiring precise laser modulation, with potential implications for signal interference in electronic communications.A laser pulser using the same laser diode LI does. I made the pulser so it could be adjusted from 50 to 20, 000ppm. I tested that on my LIs and rx65, they only alert to pulses from about 100 to 200ppm. I also wonder if my pulsure would work as a jammer if I turned the frequency all the way up, sort of like an old brute force jammer that worked really well. 🔗 External reference