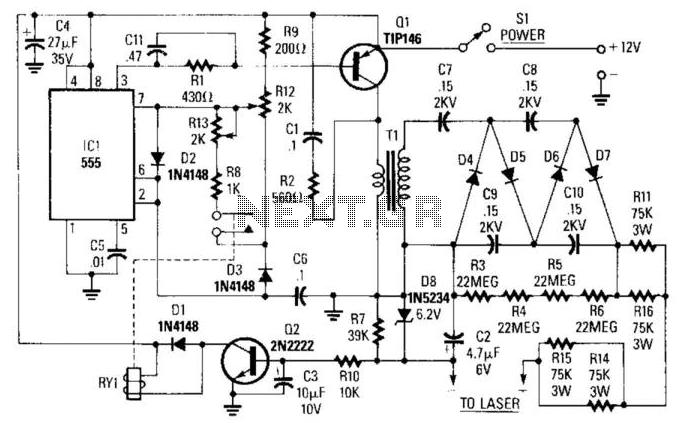

Laser Power Supply

IC1 is a 555 timer operating at approximately 16 kHz. This integrated circuit drives Q1, a TIP146 transistor, which generates a 12-V square wave across the primary winding of transformer T1. This results in an output voltage ranging from 800 to 2,000 V across the secondary winding, which is then doubled to produce an output voltage of 3 to 5 kV. When the load (laser) on the power supply increases, transistor Q2 is activated, energizing relay RY1. This action modifies the duty cycle of the 555 timer. To adjust this power supply, set resistors R12 and R13 to their center positions. Adjust R12 until the laser tube triggers and ensure that the relay engages properly. If the relay chatters, further adjustments to R12 may be necessary. If turning R12 fully clockwise does not ignite the tube, then resistor R13 should be adjusted.

The circuit described utilizes a 555 timer (IC1) configured in astable mode to generate a square wave signal at a frequency of approximately 16 kHz. This frequency is suitable for driving a power transistor (Q1), specifically a TIP146, which acts as a switch to control the primary side of transformer T1. The transformer steps up the voltage, allowing for high voltage generation across its secondary winding. The output voltage can vary significantly, ranging from 800 to 2,000 V, which is then further doubled to achieve a high-voltage output of 3 to 5 kV, essential for applications such as laser excitation.

The circuit includes a feedback mechanism that monitors the load on the power supply. As the load increases, transistor Q2 is triggered, which activates relay RY1. The engagement of the relay modifies the duty cycle of the 555 timer, allowing for dynamic adjustment of the output voltage to meet the demands of the load.

For calibration, resistors R12 and R13 are critical components. They are initially set to their mid-range values, allowing for fine-tuning of the circuit's response. Adjusting R12 influences the triggering of the laser tube; if the laser does not ignite, further adjustments to R12 are necessary. Should the relay exhibit chattering behavior during operation, indicating instability, additional tuning of R12 is required until stable operation is achieved. In cases where the laser tube does not ignite despite maxing out R12, it is advised to adjust R13 to ensure proper functioning of the circuit.

This design exemplifies a robust method for generating high voltage for laser applications, with built-in adjustments for load variations, ensuring reliable performance and operational flexibility. ICl is a 555 timer running at about 16 kHz. This IC drives Ql, a TIP146, which produces a 12-V square wave across Tl pri mary. This produces between 800 and 2,000 V across the secondary, which is doubled to 3 to 5 kV. When the load (laser) on the power supply increases, current Q2 is turned on, which energizes RY1. This changes the duty cycle of the 555 timer, lb adjust this supply, set R12 and R13 at the center. Adjust R12 until the laser tube triggers, and make sure that the relay pulls in. If the relay chatters, adjust R12. If the full-clockwise adjustment of R12 fails to ignite the tube, adjust R13. 🔗 External reference

The circuit described utilizes a 555 timer (IC1) configured in astable mode to generate a square wave signal at a frequency of approximately 16 kHz. This frequency is suitable for driving a power transistor (Q1), specifically a TIP146, which acts as a switch to control the primary side of transformer T1. The transformer steps up the voltage, allowing for high voltage generation across its secondary winding. The output voltage can vary significantly, ranging from 800 to 2,000 V, which is then further doubled to achieve a high-voltage output of 3 to 5 kV, essential for applications such as laser excitation.

The circuit includes a feedback mechanism that monitors the load on the power supply. As the load increases, transistor Q2 is triggered, which activates relay RY1. The engagement of the relay modifies the duty cycle of the 555 timer, allowing for dynamic adjustment of the output voltage to meet the demands of the load.

For calibration, resistors R12 and R13 are critical components. They are initially set to their mid-range values, allowing for fine-tuning of the circuit's response. Adjusting R12 influences the triggering of the laser tube; if the laser does not ignite, further adjustments to R12 are necessary. Should the relay exhibit chattering behavior during operation, indicating instability, additional tuning of R12 is required until stable operation is achieved. In cases where the laser tube does not ignite despite maxing out R12, it is advised to adjust R13 to ensure proper functioning of the circuit.

This design exemplifies a robust method for generating high voltage for laser applications, with built-in adjustments for load variations, ensuring reliable performance and operational flexibility. ICl is a 555 timer running at about 16 kHz. This IC drives Ql, a TIP146, which produces a 12-V square wave across Tl pri mary. This produces between 800 and 2,000 V across the secondary, which is doubled to 3 to 5 kV. When the load (laser) on the power supply increases, current Q2 is turned on, which energizes RY1. This changes the duty cycle of the 555 timer, lb adjust this supply, set R12 and R13 at the center. Adjust R12 until the laser tube triggers, and make sure that the relay pulls in. If the relay chatters, adjust R12. If the full-clockwise adjustment of R12 fails to ignite the tube, adjust R13. 🔗 External reference