ldr engineer

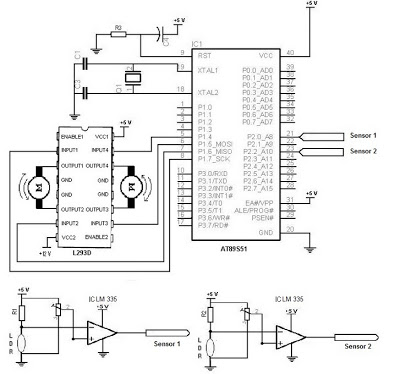

LDR (Light Dependent Resistor) engineering involves creating various electronic circuits based on the principles of a simple light and dark sensor using transistors, the 555 timer IC, and the 741 operational amplifier IC. Among the various optical sensors, the light dependent resistor is utilized for constructing light/dark sensors. A dark sensor activates a transistor or LED when the intensity of incident light diminishes, while a light sensor operates conversely. In LDR engineering, the initial step is to comprehend the operational principles of any circuit that incorporates an LDR, followed by substituting the LDR with a fixed resistor or another electronic component to transform the basic automatic light/dark sensor into a different device. Creating automatic light/dark sensor circuits using diverse methods allows for the exploration of various electronic components. Additionally, modifying these circuits into functionally different devices such as touch switches, water level indicators, and clap switches enhances understanding of those circuits. This article will demonstrate how to utilize the concept of a dark sensor to create touch and clap switches. The light dependent resistor (LDR), also known as a Cadmium Sulfide (CdS) cell or photoresistor, is a resistor whose value varies with the intensity of incident light. In darkness, the resistance of the LDR increases, while in light, the resistance decreases. This resistance variation serves as the foundation for LDR engineering circuits. The following circuit functions as a dark sensor: when light is obstructed from reaching the LDR, it activates the LED D1. This circuit is configured in monostable mode using the 555 timer, meaning the LED D1 is illuminated for a predetermined duration based on the combination of resistor R1 and capacitor C1. To modify the dark sensor circuit into a touch sensor, minor adjustments to the schematic are necessary. The LDR must be replaced with a short wire connected to the coupling capacitor, with the electrode wire approximately 2-5 cm in length. Touching this wire triggers the LED for a specific duration, as determined by resistor R1 and capacitor C1. The wire can be attached to a small metallic touch plate using an alligator clip. Another dark sensor circuit employs two transistors. When light strikes the LDR, its low resistance allows transistor Q1 (BC547) to conduct, keeping transistor Q2 in a cut-off state due to insufficient base bias. Consequently, LED D1 remains off as long as ambient light is present on the LDR. In darkness, the LDR's resistance increases, causing transistor Q1 to cease conduction and enabling transistor Q2 to conduct, activating the LED. To create a clap switch, the touch sensor and the transistorized dark sensor circuits must be combined. A condenser microphone replaces the LDR, and the collector of Q2 connects to the terminal of capacitor C2. Loud sounds near the condenser microphone trigger pin 2 of the 555 timer, turning on LED D1. Sensitivity adjustments can be made by replacing the fixed resistor R5 with a variable resistor. Following the schematic in figure 6 allows for the conversion of the two-transistor dark sensor into a single-transistor light sensor by removing R2, D1, and Q2. This circuit operates as a light sensor that turns off the LED when light on the LDR is obstructed. The light sensor can also be easily modified into a simple water level indicator by removing the LDR and submerging the wires in water. When both wires are submerged, LED D1 activates. Copper electrodes can be employed for improved performance, but they are not necessary for basic experiments. The variable resistor VR1 (470K) is used to adjust the circuit's sensitivity. The experiments outlined in this article have been tested and verified, and numerous other circuits can be developed using the principles of dark sensors.

The LDR engineering circuits utilize the fundamental properties of light dependent resistors to create versatile electronic devices. The core mechanism of these circuits relies on the variation of resistance in response to light intensity, allowing the construction of sensors that react to environmental changes. The monostable configuration of the 555 timer in the dark sensor circuit is crucial for timing applications, enabling the LED to remain illuminated for a specified duration, which can be adjusted by changing the values of R1 and C1.

The transition from a dark sensor to a touch sensor is a practical demonstration of how circuit components can be repurposed. The use of a wire in place of the LDR illustrates adaptability in circuit design, allowing for user interaction through touch. This aspect of LDR engineering emphasizes the importance of understanding the underlying principles of electronic components and how they can be manipulated to achieve different functionalities.

The two-transistor dark sensor circuit exemplifies the use of transistors in sensing applications. The interaction between Q1 and Q2 showcases a fundamental principle of electronic circuits: the ability to control one component through another. This principle is critical in various applications, from simple sensors to complex automation systems.

The clap switch design integrates audio sensing through a condenser microphone, broadening the application of LDR engineering concepts. This feature highlights the versatility of the technology and its potential for innovative applications in user interfaces and automation.

Overall, LDR engineering provides a foundation for understanding and creating a wide array of electronic circuits. The principles discussed can be applied to numerous projects, encouraging experimentation and innovation in the field of electronics.LDR( Light dependent resistor ) Engineering is a technique of making several electronics circuits following thelogic of a simple light and dark sensor using transistors, 555 IC and 741 IC. Out of several optical sensors, light dependent resistor can beused for making light/dark sensors. A dark sensor switches on transistor or LED wheneverthe incid ent light intensity is decreased, whereasa light sensor works in opposite way. In LDREngineering, we first understand the working principle of any circuit using LDR, and then we replace the LDRwith a fixed resistor or some other electronic component that makes the simple automatic light/dark sensor work as a completely different device. Making automatic light/dark sensor circuits using different methods can make you observe several electronics components.

On the other hand, modifying those automatic light/dark sensor circuits to some functionally different circuits like touch switch, water level indicator, clap switch, etc. can make you understand about those circuits. In this article, we will see how we can use the concept of a dark sensor to make a touch and a clap switch.

Light dependent resistor (LDR), also called as Cadmium Sulphide (CdS) cell or photoresistoris a resistor whose value depends upon the incident light intensity. In darkness, the resistance ofLDRbecomes high and in light, the resistance gets low. The resistance variation phenomenon of LDRhas been takenas a base for making circuits of LDR Engineering.

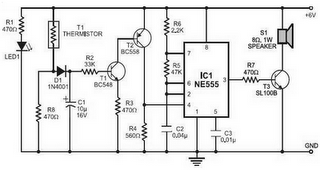

The following circuit works as a dark sensor. If the light falling on LDRis blocked, it switches on the LED D1. It has been configuredin monostablemode of 555 timer which means that the circuit switches on the LED D1for a specific time. The switching time is determined by thecombination of resistance R1and capacitor C1. We can make the previous dark sensor circuit work as a touch sensor by making small changes in the schematic.

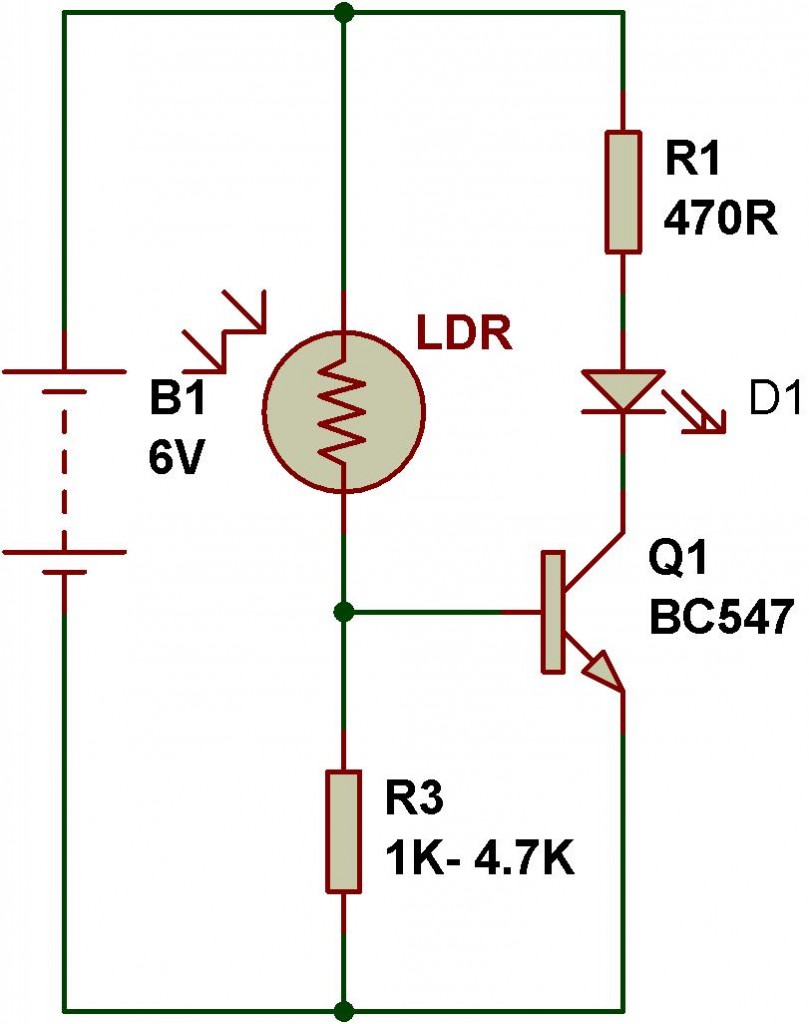

We just need to remove the LDR, put a small wire and connect it to the coupling capacitor. Note that the electrode wire connected to capacitor C2should bearound 2-5cmlong. As we touch on the wire, the circuit triggers the LED for a specific time as determined by the resistor R1and capacitor C1. You can connect the wire to a small metallic touch plate using an alligator clip. Here, we have another dark sensor that works with two transistors. When light falls on LDR, its low resistance drives transistor Q1-BC547into conduction. This keeps transistor Q2 cut-off due to low basebias. The LED D1does not get power as long as ambient light falls on LDR. When the resistance ofLDR becomes high in darkness, transistor Q1 stops conducting and transistor Q2 starts conducting to turn on the LED.

In order to make a clap switch, we have to combine the previous touch sensor and the transistorizeddark sensor circuits. We also need to connect a condenser microphone in place of LDRand the collector of Q2 has to beconnected to the terminal of capacitor C2.

Whenever there is loud sound produced near the condenser mic, pin 2 of 555 gets triggered and it switches on the LED D1. We can adjust the sensitivity ofthe circuit using a variable resistor in place of fixed resistor R5. If we follow the schematic of figure 6, we can convert the two transistor dark sensor to single transistor light sensor by removing R2, D1and Q2.

The circuit works as a light sensor which switches off the LED wheneverlight falling on LDRis blocked. Now, the light sensor can beeasily converted to a simple water level indicator. We just need to remove the LDR, and dip the wires into water. When both wires are dipped, the circuit switches on the LED D1. We can use copper electrodes for better performance, but for normal experiment, we don`t need any electrode.

VR1-470Kis for adjusting the sensitivity of the circuit. The experiments given in this article have been testedand verified. We can make several other circuits using the idea of da 🔗 External reference

The LDR engineering circuits utilize the fundamental properties of light dependent resistors to create versatile electronic devices. The core mechanism of these circuits relies on the variation of resistance in response to light intensity, allowing the construction of sensors that react to environmental changes. The monostable configuration of the 555 timer in the dark sensor circuit is crucial for timing applications, enabling the LED to remain illuminated for a specified duration, which can be adjusted by changing the values of R1 and C1.

The transition from a dark sensor to a touch sensor is a practical demonstration of how circuit components can be repurposed. The use of a wire in place of the LDR illustrates adaptability in circuit design, allowing for user interaction through touch. This aspect of LDR engineering emphasizes the importance of understanding the underlying principles of electronic components and how they can be manipulated to achieve different functionalities.

The two-transistor dark sensor circuit exemplifies the use of transistors in sensing applications. The interaction between Q1 and Q2 showcases a fundamental principle of electronic circuits: the ability to control one component through another. This principle is critical in various applications, from simple sensors to complex automation systems.

The clap switch design integrates audio sensing through a condenser microphone, broadening the application of LDR engineering concepts. This feature highlights the versatility of the technology and its potential for innovative applications in user interfaces and automation.

Overall, LDR engineering provides a foundation for understanding and creating a wide array of electronic circuits. The principles discussed can be applied to numerous projects, encouraging experimentation and innovation in the field of electronics.LDR( Light dependent resistor ) Engineering is a technique of making several electronics circuits following thelogic of a simple light and dark sensor using transistors, 555 IC and 741 IC. Out of several optical sensors, light dependent resistor can beused for making light/dark sensors. A dark sensor switches on transistor or LED wheneverthe incid ent light intensity is decreased, whereasa light sensor works in opposite way. In LDREngineering, we first understand the working principle of any circuit using LDR, and then we replace the LDRwith a fixed resistor or some other electronic component that makes the simple automatic light/dark sensor work as a completely different device. Making automatic light/dark sensor circuits using different methods can make you observe several electronics components.

On the other hand, modifying those automatic light/dark sensor circuits to some functionally different circuits like touch switch, water level indicator, clap switch, etc. can make you understand about those circuits. In this article, we will see how we can use the concept of a dark sensor to make a touch and a clap switch.

Light dependent resistor (LDR), also called as Cadmium Sulphide (CdS) cell or photoresistoris a resistor whose value depends upon the incident light intensity. In darkness, the resistance ofLDRbecomes high and in light, the resistance gets low. The resistance variation phenomenon of LDRhas been takenas a base for making circuits of LDR Engineering.

The following circuit works as a dark sensor. If the light falling on LDRis blocked, it switches on the LED D1. It has been configuredin monostablemode of 555 timer which means that the circuit switches on the LED D1for a specific time. The switching time is determined by thecombination of resistance R1and capacitor C1. We can make the previous dark sensor circuit work as a touch sensor by making small changes in the schematic.

We just need to remove the LDR, put a small wire and connect it to the coupling capacitor. Note that the electrode wire connected to capacitor C2should bearound 2-5cmlong. As we touch on the wire, the circuit triggers the LED for a specific time as determined by the resistor R1and capacitor C1. You can connect the wire to a small metallic touch plate using an alligator clip. Here, we have another dark sensor that works with two transistors. When light falls on LDR, its low resistance drives transistor Q1-BC547into conduction. This keeps transistor Q2 cut-off due to low basebias. The LED D1does not get power as long as ambient light falls on LDR. When the resistance ofLDR becomes high in darkness, transistor Q1 stops conducting and transistor Q2 starts conducting to turn on the LED.

In order to make a clap switch, we have to combine the previous touch sensor and the transistorizeddark sensor circuits. We also need to connect a condenser microphone in place of LDRand the collector of Q2 has to beconnected to the terminal of capacitor C2.

Whenever there is loud sound produced near the condenser mic, pin 2 of 555 gets triggered and it switches on the LED D1. We can adjust the sensitivity ofthe circuit using a variable resistor in place of fixed resistor R5. If we follow the schematic of figure 6, we can convert the two transistor dark sensor to single transistor light sensor by removing R2, D1and Q2.

The circuit works as a light sensor which switches off the LED wheneverlight falling on LDRis blocked. Now, the light sensor can beeasily converted to a simple water level indicator. We just need to remove the LDR, and dip the wires into water. When both wires are dipped, the circuit switches on the LED D1. We can use copper electrodes for better performance, but for normal experiment, we don`t need any electrode.

VR1-470Kis for adjusting the sensitivity of the circuit. The experiments given in this article have been testedand verified. We can make several other circuits using the idea of da 🔗 External reference