led lighting for 6v vehicles

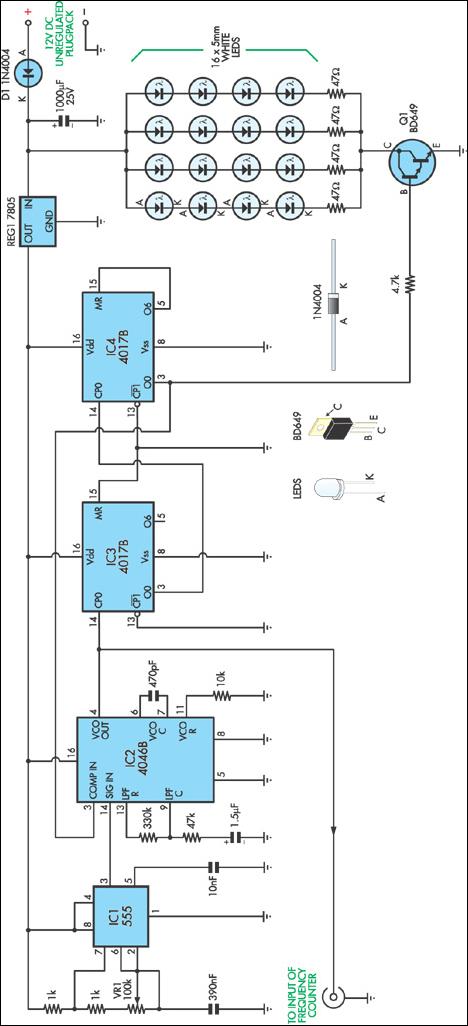

This design replaces the incandescent bulbs in the stop, tail, and indicator lights of an MZ or other motorcycle with a six-volt electrical system using high-intensity Lumiled LEDs. This modification offers several advantages: a single Lumiled consumes approximately 1.2W yet produces light output equivalent to a color-filtered 21W incandescent bulb, significantly reducing the load on the electrical system. The saved power can be redirected to operate a more powerful headlamp bulb. Unlike incandescent bulbs, LEDs do not burn out and are resistant to vibration, eliminating the need for replacements. Consequently, the light units can be permanently sealed and waterproofed with silicone sealant or similar materials, with connections to the LEDs made via soldered joints rather than contacts. This enhances the reliability of the lighting system compared to the standard incandescent setup. The color of the light is determined by the semiconductor material of the LEDs rather than through filtering with a colored lens. Therefore, if the lens is damaged or broken in an accident, the lights will still emit the correct color. Unlike incandescent bulbs, LEDs require external circuitry to limit current to a safe level, typically achieved with a series resistor. However, this method is unsuitable for a six-volt automotive electrical system. The LED operates with a voltage drop of approximately 3 volts, while the supply voltage may fluctuate between about 5 volts to 7 volts or more, depending on the battery's state of charge and engine speed. This leads to a variation of approximately 2:1 in the voltage across the series resistor, resulting in a corresponding 2:1 variation in LED brightness. The current is primarily determined by the value of the emitter resistor of the TIP110. Due to component variations, it is necessary to adjust this resistor value to achieve the correct current, which is 320mA for an indicator or stop light and 80mA for the tail light. The approximate resistor values are 2.4 ohms for 320mA and 10 ohms for 80mA. Actual currents should be measured, and the resistor value adjusted accordingly. The use of a variable resistor is not recommended for reliability reasons. The 2.4-ohm resistors should have a power rating of 0.5W. It is important to note that the absolute maximum permitted current for a Lumiled is 350mA. Heat generated in the TIP110 can lead to an increase in regulated current, so it is advisable to attach a heatsink to the TIP110. This can be effectively accomplished by constructing the circuit within a diecast metal box and securely bolting the TIP110 to the box using appropriate insulating washers and thermal transfer grease. The yellow LED serves to provide the bias voltage for the constant current source; a green LED could be used as an alternative, but red or blue LEDs are not suitable. These bias LEDs do not need to be visible. The two series 47-ohm resistors across the circuit are intended to ensure the proper functioning of the flasher unit. A single 100-ohm, 0.5-watt resistor can serve the same purpose and is not required for the stop or tail lights. The 470uF capacitor is optional and may be omitted if desired; its function is to allow the LED to turn on gradually, mimicking the behavior of an incandescent bulb. This gradual illumination may be beneficial to circumvent regulations that prohibit the use of LEDs for vehicle lights unless incandescent bulbs are also installed as the primary light source.

The proposed circuit design focuses on integrating high-efficiency Lumiled LEDs into the existing motorcycle lighting system, enhancing both performance and reliability. The circuit utilizes a TIP110 transistor configured as a constant current source, ensuring that the LEDs receive a stable current regardless of variations in supply voltage. The inclusion of a heatsink for the TIP110 is crucial to prevent thermal runaway, which can occur due to heat buildup during operation.

The design incorporates a series resistor to manage current flow, with specific values calculated based on the desired current for each light type. The choice of a fixed resistor instead of a variable one is made to maintain reliability over time. The biasing of the TIP110 with a yellow LED ensures consistent performance, while the additional resistors serve to stabilize the flasher unit's operation, ensuring that the lights function correctly during signaling.

The optional capacitor smooths the LED turn-on characteristics, providing a more gradual illumination that mimics incandescent bulbs. This feature addresses potential regulatory concerns regarding the use of LEDs in automotive applications, making the design more compliant with such regulations. Overall, this circuit design represents a significant advancement in motorcycle lighting technology, offering improved efficiency, durability, and safety.This design replaces the incandescent bulbs in the stop, tail and indicator lights of an MZ or other motorcycle with a six-volt electrical system,with high-intensity Lumiled LEDs. This gives the following advantages: A single Lumiled with a power consumption of around 1. 2W gives a light output equivalent to a colour-filtered 21W incandescent bulb. The load on the electrical system is therefore considerably reduced. The power saved may be used to drive a more powerful headlamp bulb. Unlike incandescent bulbs, LEDs do not burn out, and are not affected by vibration. Therefore, they do not need to be replaced. Accordingly, the light units may be permanently sealed and waterproofed with silicone sealant or similar, and connections to the LEDs made by soldered connections rather than contacts. The reliability of the lighting system is therefore much greater than the standard incandescent system.

The colour of the light is determined by the properties of the semiconductor material from which the LEDs are made, and not by filtering with a coloured lens. Therefore, should the lens be damaged or broken in an accident, the lights will continue to show the correct colour.

Unlike an incandescent bulb, an LED requires external circuitry to limit the current taken to a safe value. This is generally done with a simple series resistor. However, this approach is not suitable for a six-volt automotive electrical system. The LED will drop about 3 volts in operation, and the supply voltage may vary from about 5 volts to 7 volts or more depending on the state of charge of the battery and the engine speed.

This would result in a variation of about 2:1 in the voltage across the series resistor, with a consequent 2:1 variation in the brightness of the LED. The current is nominally determined by the value of the emitter resistor of the TIP110. Due to component variations it will be necessary to adjust the value of this resistor to obtain the correct current, which is 320mA for an indicator or stop light and 80mA for the tail light.

Approximately correct currents will be given by using 2. 4 ohms for 320mA, and 10 ohms for 80mA. The actual currents should be measured and the resistor changed in accordance with the result. Use of a variable resistor is NOT recommended, for reasons of reliability. The 2. 4 ohm resistors should be rated at 0. 5W. Note that the absolute maximum permitted current for a Lumiled is 350mA. Heat dissipated in the TIP110 has the unfortunate effect of causing the regulated current to rise. To avoid this the TIP110 should be heatsunk. This is most easily done by building the circuit in a diecast metal box and bolting the TIP110 to the box with suitable insulating washers and thermal transfer grease. The purpose of the yellow LED is to provide the bias voltage for the constant current source. A green LED could be used instead, but a red or blue LED would NOT be suitable. There is no requirement for these bias LEDs to be visible. The two series 47 ohm resistors across the entire circuit are to ensure correct operation of the flasher unit (see later).

A single 100 ohm 0. 5 watt resistor will do just as well. They are not required in the stop or tail lights. The 470uF capacitor is optional and may be left out if desired. Its purpose is to cause the LED to turn on gradually, in a similar manner to an incandescent bulb, and thereby disguise the fact that an LED is fitted. This may be thought desirable in order to avoid possible problems due to incredibly stupid regulations which forbid the use of LEDs for vehicle lights unless incandescent bulbs are also fitted as the primary light source.

(If anyone responsible for such regulations is reading this: GET A CLUE ALREADY. ) I 🔗 External reference

The proposed circuit design focuses on integrating high-efficiency Lumiled LEDs into the existing motorcycle lighting system, enhancing both performance and reliability. The circuit utilizes a TIP110 transistor configured as a constant current source, ensuring that the LEDs receive a stable current regardless of variations in supply voltage. The inclusion of a heatsink for the TIP110 is crucial to prevent thermal runaway, which can occur due to heat buildup during operation.

The design incorporates a series resistor to manage current flow, with specific values calculated based on the desired current for each light type. The choice of a fixed resistor instead of a variable one is made to maintain reliability over time. The biasing of the TIP110 with a yellow LED ensures consistent performance, while the additional resistors serve to stabilize the flasher unit's operation, ensuring that the lights function correctly during signaling.

The optional capacitor smooths the LED turn-on characteristics, providing a more gradual illumination that mimics incandescent bulbs. This feature addresses potential regulatory concerns regarding the use of LEDs in automotive applications, making the design more compliant with such regulations. Overall, this circuit design represents a significant advancement in motorcycle lighting technology, offering improved efficiency, durability, and safety.This design replaces the incandescent bulbs in the stop, tail and indicator lights of an MZ or other motorcycle with a six-volt electrical system,with high-intensity Lumiled LEDs. This gives the following advantages: A single Lumiled with a power consumption of around 1. 2W gives a light output equivalent to a colour-filtered 21W incandescent bulb. The load on the electrical system is therefore considerably reduced. The power saved may be used to drive a more powerful headlamp bulb. Unlike incandescent bulbs, LEDs do not burn out, and are not affected by vibration. Therefore, they do not need to be replaced. Accordingly, the light units may be permanently sealed and waterproofed with silicone sealant or similar, and connections to the LEDs made by soldered connections rather than contacts. The reliability of the lighting system is therefore much greater than the standard incandescent system.

The colour of the light is determined by the properties of the semiconductor material from which the LEDs are made, and not by filtering with a coloured lens. Therefore, should the lens be damaged or broken in an accident, the lights will continue to show the correct colour.

Unlike an incandescent bulb, an LED requires external circuitry to limit the current taken to a safe value. This is generally done with a simple series resistor. However, this approach is not suitable for a six-volt automotive electrical system. The LED will drop about 3 volts in operation, and the supply voltage may vary from about 5 volts to 7 volts or more depending on the state of charge of the battery and the engine speed.

This would result in a variation of about 2:1 in the voltage across the series resistor, with a consequent 2:1 variation in the brightness of the LED. The current is nominally determined by the value of the emitter resistor of the TIP110. Due to component variations it will be necessary to adjust the value of this resistor to obtain the correct current, which is 320mA for an indicator or stop light and 80mA for the tail light.

Approximately correct currents will be given by using 2. 4 ohms for 320mA, and 10 ohms for 80mA. The actual currents should be measured and the resistor changed in accordance with the result. Use of a variable resistor is NOT recommended, for reasons of reliability. The 2. 4 ohm resistors should be rated at 0. 5W. Note that the absolute maximum permitted current for a Lumiled is 350mA. Heat dissipated in the TIP110 has the unfortunate effect of causing the regulated current to rise. To avoid this the TIP110 should be heatsunk. This is most easily done by building the circuit in a diecast metal box and bolting the TIP110 to the box with suitable insulating washers and thermal transfer grease. The purpose of the yellow LED is to provide the bias voltage for the constant current source. A green LED could be used instead, but a red or blue LED would NOT be suitable. There is no requirement for these bias LEDs to be visible. The two series 47 ohm resistors across the entire circuit are to ensure correct operation of the flasher unit (see later).

A single 100 ohm 0. 5 watt resistor will do just as well. They are not required in the stop or tail lights. The 470uF capacitor is optional and may be left out if desired. Its purpose is to cause the LED to turn on gradually, in a similar manner to an incandescent bulb, and thereby disguise the fact that an LED is fitted. This may be thought desirable in order to avoid possible problems due to incredibly stupid regulations which forbid the use of LEDs for vehicle lights unless incandescent bulbs are also fitted as the primary light source.

(If anyone responsible for such regulations is reading this: GET A CLUE ALREADY. ) I 🔗 External reference