Light Detector

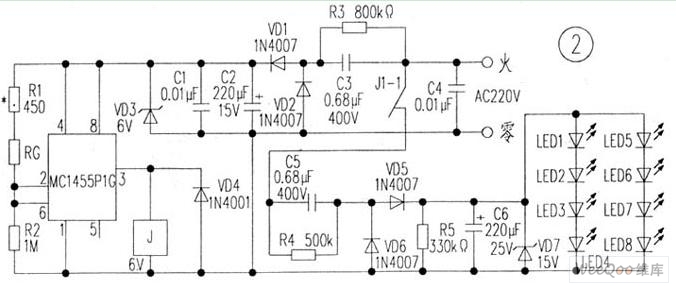

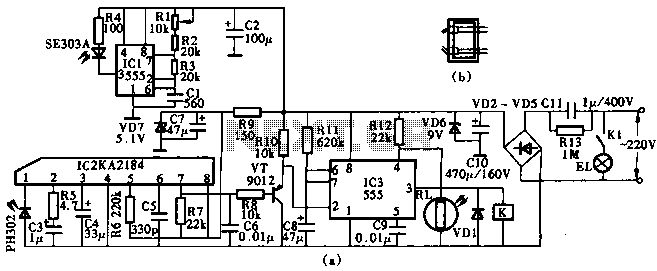

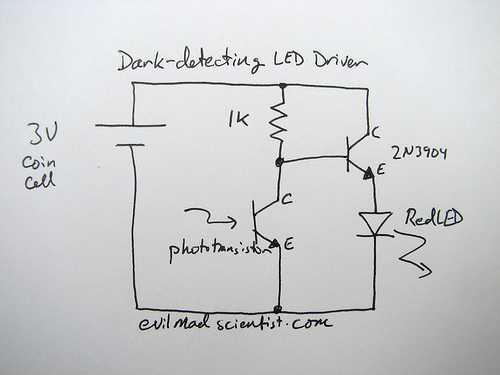

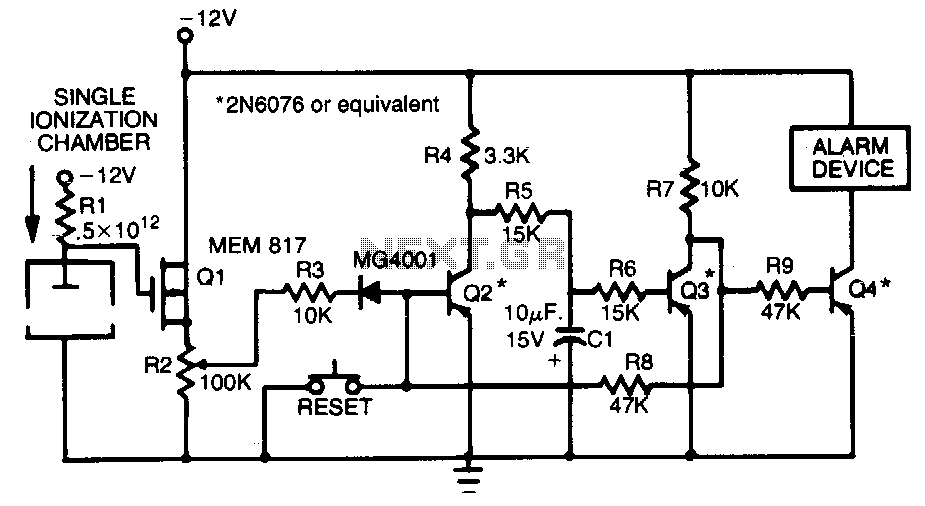

The comparator output drives an LED, and the next step is to sense the intensity of the LED. This lab involves building a light detector circuit using an operational amplifier (op-amp) and a standard light-emitting diode (LED). It is well-known that an LED emits light when current flows through it, but it can also function in reverse. When exposed to light, an LED generates a small current from cathode to anode due to the photovoltaic effect. This property enables LEDs to be used not only for light production but also for light detection. The small current can be amplified into a larger voltage through a transimpedance amplifier. However, certain limitations exist; for instance, LEDs are most effective at detecting light wavelengths shorter than those they emit. The circuit will initially utilize the same type of blue LED employed in the PWM Generator lab. The output voltage will be proportional to the intensity of ambient light, meaning that higher incident light intensity results in a higher output voltage from the ambient light sensor circuit. The circuit schematic provided should be constructed, with V_out connected to an analog input channel for observation on an oscilloscope. The operation of the circuit is straightforward: when light illuminates the LED, a corresponding reverse current flows through it. Ideal operational amplifier characteristics dictate that both input terminals remain at 0 volts. The current direction, indicated by blue arrows, will be used to calculate the output voltage in relation to resistance. Thus, a very small current can produce a measurable output voltage. To test the circuit, shine the light from the LED output of the comparator directly onto the LED of the light detector, ensuring the tops of the LEDs face each other. Increasing the DAC output will brighten the LED, consequently increasing the measured voltage at the light detector circuit's output. When the digital I/O pins are set to 0111 1111, or half of the full value, a specific waveform capture can be observed. The frequency of this captured waveform is 2.694 kHz, corresponding to the triangle wave generator's frequency. The duty cycle of the captured waveform is 49.8%, as the DAC was set to 50% of full scale. Most remote controls for electronic devices utilize a near-infrared diode to emit a beam of light that reaches the device. A typical wavelength for this is 940 nm, which is invisible to the human eye but detectable by sensors in the receiving device. By toggling the diode at a specific frequency and modulating data (such as keystrokes from the remote), wireless communication can occur with the target device (e.g., TV, radio). In the experiment, an infrared detector within the appliance converts the received light pulses into digital data. Various manufacturers employ different protocols for transmitting infrared commands. The RC-5 protocol, originating from Philips, uses a total of 14 bits for each button press, with the bit pattern modulated onto a carrier frequency that varies among manufacturers; for RC-5, a 36 kHz carrier is utilized. Other consumer infrared protocols include various SIRCS versions from Sony, RC-6 from Philips, Ruwido R-Step, and the NEC TC101 protocol. By replacing the blue LED in the previous section with a yellow one, infrared light can be detected in a standard remote control.

The light detector circuit described utilizes a light-emitting diode (LED) to sense ambient light levels through its photovoltaic effect. The circuit is designed around an operational amplifier configured as a transimpedance amplifier, which converts the small current produced by the LED when exposed to light into a measurable output voltage. The LED operates in reverse mode, generating a current when illuminated, which is then amplified by the op-amp.

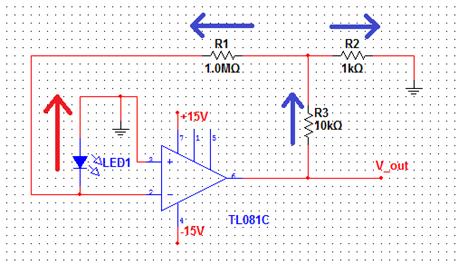

In the schematic, the LED is connected in reverse bias to the op-amp input. The output voltage (V_out) is taken from the op-amp's output pin and is linked to an analog input channel for real-time monitoring via an oscilloscope. The circuit's performance is characterized by the relationship between the light intensity and the output voltage, allowing for an intuitive understanding of ambient light levels. The LED's sensitivity to light wavelengths shorter than its emission spectrum is critical, as this characteristic enhances the accuracy of light detection.

In practical applications, the circuit can be utilized in various settings, including automatic lighting systems, light-sensitive alarms, and even in remote control systems, where infrared light detection is crucial. The ability to modulate the output of the LED and observe the corresponding changes in the output voltage allows for straightforward experimentation and calibration of the system.

In summary, the described light detector circuit effectively demonstrates the dual functionality of LEDs, serving both as light sources and sensors. Its design leverages the principles of operational amplifiers and the photovoltaic effect, offering a versatile tool for various electronic applications.With the comparator output driving an LED, the next step will be to sense the intensity of the LED. This lab will build a light detector circuit using an op amp and an everyday light emitting diode (LED). It`s common knowledge that when a current flows through an LED it emits light, but you may not have known that they also work in reverse.

When a n LED is exposed to light, it will create a small current from cathode to anode due to the photovoltaic effect. Using this property of LEDs, we can use them not only to produce light, but to detect it as well. This small current then can be amplified into a large voltage through the use of a transimpedance amplifier.

However there are some limitations to this approach. First, LEDs best detect light at wavelengthsshorter thanthe light they normally emit. This circuit will first be performed using the same type of blue LED that is used in the PWM Generator lab. This circuit will output a voltage that is proportional to the intensity of ambient light. The higher intensity the incident light the LED is exposed to, the higher the output voltage of the ambient light sensor circuit will be.

The following schematic will be used to sense ambient light. Build the circuit in the schematic below. Connect V_out to one of the analog input channels so that it can be observed on the oscilloscope. This circuit can be described very simply. When light shines on a LED there is a corresponding current that flows backwards through the LED (direction shown by red arrow in Figure Z. 1). Also, by characteristics of ideal operational amplifiers, both input terminals equal 0 volts. The blue arrows represent the direction of current that will be used to solve for output voltage in terms of resistance.

This means that a very small current can correspond to a measurable output voltage. To test this circuit shine the light from the LED on the output of the comparator directly at the LED of the light detector (point the tops of the LEDs towards each other). By increasing the output of the DAC the LED will get brighter and the measured voltage on the output of the light detector circuit will increase.

By setting the output of the digital I/O pins to 0111 1111, or half of full value the following capture was made. Notice that the Frequency of the captured waveform is at 2. 694 kHz which is what the frequency of the triangle wave generator was set at. Also note that the duty cycle of the captured is at 49. 8% due to the fact the DAC was set at 50% of full scale. Most remote controls for electronic appliances use a near infrared diode to emit a beam of light that reaches the device.

A 940 nm wavelength LED is typical. This infrared light is invisible to the human eye, but picked up by sensors on the receiving device. By turning on and off the diode at a specific frequency and modulating (adding or mixing) data (keystrokes from the remote), a device can communicate wirelessly to the intended target (tv, radio, etc. ). Looking back at your experiment, you can imagine an infrared detector in the appliance that will convert the pulses of light received to digital data.

Different manufacturers of infrared remote controls use different protocols to transmit the infrared commands. The RC-5 protocol that has its origins within Philips, uses, for instance, a total of 14 bits for each button press.

The bit pattern is modulated onto a carrier frequency that, again, can be different for different manufacturers and standards, in the case of RC-5, a 36kHz carrier is being used. Other consumer infrared protocols are, for instance, the different SIRCS versions used by Sony, the RC-6 from Philips, the Ruwido R-Step, or the NEC TC101 protocol.

By changing the LED in the previous section from Blue to Yellow the IR light can be sensed in an everyday remote control. Below is a capture taken from pointing a remote control at the light detector circuit with and yellow LED in p

🔗 External reference

The light detector circuit described utilizes a light-emitting diode (LED) to sense ambient light levels through its photovoltaic effect. The circuit is designed around an operational amplifier configured as a transimpedance amplifier, which converts the small current produced by the LED when exposed to light into a measurable output voltage. The LED operates in reverse mode, generating a current when illuminated, which is then amplified by the op-amp.

In the schematic, the LED is connected in reverse bias to the op-amp input. The output voltage (V_out) is taken from the op-amp's output pin and is linked to an analog input channel for real-time monitoring via an oscilloscope. The circuit's performance is characterized by the relationship between the light intensity and the output voltage, allowing for an intuitive understanding of ambient light levels. The LED's sensitivity to light wavelengths shorter than its emission spectrum is critical, as this characteristic enhances the accuracy of light detection.

In practical applications, the circuit can be utilized in various settings, including automatic lighting systems, light-sensitive alarms, and even in remote control systems, where infrared light detection is crucial. The ability to modulate the output of the LED and observe the corresponding changes in the output voltage allows for straightforward experimentation and calibration of the system.

In summary, the described light detector circuit effectively demonstrates the dual functionality of LEDs, serving both as light sources and sensors. Its design leverages the principles of operational amplifiers and the photovoltaic effect, offering a versatile tool for various electronic applications.With the comparator output driving an LED, the next step will be to sense the intensity of the LED. This lab will build a light detector circuit using an op amp and an everyday light emitting diode (LED). It`s common knowledge that when a current flows through an LED it emits light, but you may not have known that they also work in reverse.

When a n LED is exposed to light, it will create a small current from cathode to anode due to the photovoltaic effect. Using this property of LEDs, we can use them not only to produce light, but to detect it as well. This small current then can be amplified into a large voltage through the use of a transimpedance amplifier.

However there are some limitations to this approach. First, LEDs best detect light at wavelengthsshorter thanthe light they normally emit. This circuit will first be performed using the same type of blue LED that is used in the PWM Generator lab. This circuit will output a voltage that is proportional to the intensity of ambient light. The higher intensity the incident light the LED is exposed to, the higher the output voltage of the ambient light sensor circuit will be.

The following schematic will be used to sense ambient light. Build the circuit in the schematic below. Connect V_out to one of the analog input channels so that it can be observed on the oscilloscope. This circuit can be described very simply. When light shines on a LED there is a corresponding current that flows backwards through the LED (direction shown by red arrow in Figure Z. 1). Also, by characteristics of ideal operational amplifiers, both input terminals equal 0 volts. The blue arrows represent the direction of current that will be used to solve for output voltage in terms of resistance.

This means that a very small current can correspond to a measurable output voltage. To test this circuit shine the light from the LED on the output of the comparator directly at the LED of the light detector (point the tops of the LEDs towards each other). By increasing the output of the DAC the LED will get brighter and the measured voltage on the output of the light detector circuit will increase.

By setting the output of the digital I/O pins to 0111 1111, or half of full value the following capture was made. Notice that the Frequency of the captured waveform is at 2. 694 kHz which is what the frequency of the triangle wave generator was set at. Also note that the duty cycle of the captured is at 49. 8% due to the fact the DAC was set at 50% of full scale. Most remote controls for electronic appliances use a near infrared diode to emit a beam of light that reaches the device.

A 940 nm wavelength LED is typical. This infrared light is invisible to the human eye, but picked up by sensors on the receiving device. By turning on and off the diode at a specific frequency and modulating (adding or mixing) data (keystrokes from the remote), a device can communicate wirelessly to the intended target (tv, radio, etc. ). Looking back at your experiment, you can imagine an infrared detector in the appliance that will convert the pulses of light received to digital data.

Different manufacturers of infrared remote controls use different protocols to transmit the infrared commands. The RC-5 protocol that has its origins within Philips, uses, for instance, a total of 14 bits for each button press.

The bit pattern is modulated onto a carrier frequency that, again, can be different for different manufacturers and standards, in the case of RC-5, a 36kHz carrier is being used. Other consumer infrared protocols are, for instance, the different SIRCS versions used by Sony, the RC-6 from Philips, the Ruwido R-Step, or the NEC TC101 protocol.

By changing the LED in the previous section from Blue to Yellow the IR light can be sensed in an everyday remote control. Below is a capture taken from pointing a remote control at the light detector circuit with and yellow LED in p

🔗 External reference