Line Follower Robot

Designing a simple yet functional Line Follower Robot (LFR) is a fascinating and challenging topic. The LFR can be implemented in various ways, ranging from a basic two-transistor design to a sophisticated PID (Proportional, Integral, and Derivative) controller that utilizes the programmable features of a microcontroller to compute the PID equation for effective navigation along a black track line on a white background. Creating a non-microcontroller-based LFR is a challenging task, as it requires limiting the number of electronic components to ensure that the robot remains manageable for average robotics beginners or electronic hobbyists. However, it is crucial to incorporate a reliable speed control mechanism to enable successful navigation of the black track line. Conversely, a microcontroller-based LFR is a popular choice due to its reduced component count and flexible programmable control. This tutorial will demonstrate how to build an LFR using standard analog components readily available in the market, employing the same speed control techniques found in many effective microcontroller-based designs. The result is a precise analog line follower robot comparable to its microcontroller-based counterparts. This tutorial will also provide valuable information on using operational amplifiers. The Line Follower Robot will primarily utilize a Cadmium Sulphide (CdS) photocell sensor, also known as a Light Dependent Resistor (LDR), along with a high-intensity blue Light Emitting Diode (LED) to illuminate the area beneath the photocell sensor to detect the black track line. The DC motor speed control technique will be employed to navigate the track. A straightforward method for navigating the black track line involves turning the left or right DC motor ON and OFF based on sensor readings (black turns OFF and white turns ON). However, this method may cause the LFR to move in a zigzag pattern. By proportionally controlling the speeds of both left and right DC motors according to the light intensity received from the photocell sensor (reflected by the black track line), the LFR can effectively navigate the track. A common technique for efficient motor speed control is pulse width modulation (PWM). PWM is essentially an ON and OFF pulse signal with a constant frequency. The ratio of the ON time to the total pulse period is referred to as the duty cycle, expressed as a percentage. For instance, a duty cycle of 50% indicates that the ON time constitutes half of the total pulse period. The PWM duty cycle percentage correlates with the average power produced by the signal; a lower percentage results in less power, while a higher percentage yields more power. By adjusting the PWM duty cycle, the average voltage across the DC motor terminals can be varied, thus changing the motor speed. To ensure smooth navigation along the black track line, the PWM duty cycle must be adjusted according to the photocell sensor readings. A higher light intensity detected by the sensor (indicating a white surface) will result in a higher PWM duty cycle percentage, while a lower light intensity (indicating the black line) will yield a lower PWM duty cycle percentage. By converting the photocell sensor's light intensity readings into corresponding voltage levels, this objective can be achieved using the Voltage Control Pulse Width Modulation principle. Generating the PWM signal is generally simpler with a microcontroller than with discrete components, as it only requires programming.

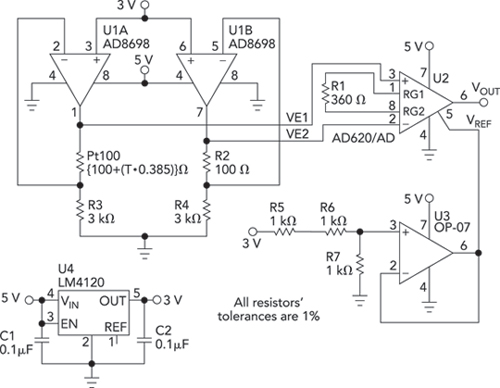

The schematic for a Line Follower Robot using analog components typically includes the following key elements:

1. **Photocell Sensor and LED**: The CdS photocell sensor is connected in a voltage divider configuration with a resistor. The LED is placed to illuminate the area being sensed, enhancing the contrast between the black track and the white surface.

2. **Operational Amplifier**: An operational amplifier is used to amplify the voltage signal from the photocell. The output of the op-amp is then fed into a comparator circuit that determines the light intensity level.

3. **Motor Driver Circuit**: The outputs from the comparator can control a H-bridge motor driver circuit. The motor driver controls the direction and speed of the DC motors based on the PWM signal generated from the op-amp output.

4. **PWM Generation**: The PWM signal can be generated using a 555 timer IC configured in astable mode. The duty cycle of the PWM signal can be modulated based on the op-amp output, which corresponds to the light intensity detected by the photocell.

5. **DC Motors**: Two DC motors are used for movement, with their speeds controlled by the PWM signals. The motors are connected to the H-bridge, allowing for bidirectional control.

6. **Power Supply**: A suitable power supply is required to power the motors and the control circuitry. Voltage regulators may be employed to ensure that the op-amp and other components receive the appropriate voltage levels.

The overall design aims to achieve responsive and smooth navigation along the track, minimizing zigzag movements through proportional speed adjustments based on sensor feedback. Proper calibration and tuning of the components will enhance the performance of the LFR, making it an effective educational project for beginners in robotics and electronics.Designing a simple and yet functional Line Follower Robot (LFR) is always a fascinating and challenging subject to be learned, the LFR actually could be implemented in many ways start from a simple two transistors to a sophisticated PID (Proportional, Integrate and Differential) which take advantage of the programmable feature of microcontroller t o calculate the PID equation to successfully navigate the black track line on a white background surface. Designing a non microcontroller based LFR is quite challenging tasks as we need to limit the electronic components numbers so the LFR will not too complicated to be built by most average robotics beginners or electronic hobbyists, but at the same time we need to have a good speed control mechanism in order for the LFR to navigate the black track line successfully.

The microcontroller based design LFR in the other hand is a popular choice because it reduces a number of electronic components significantly while still providing a flexible programmable control to the LFR. On this tutorial we are going to build yet another LFR using just the standard analog components easily found on the market but use the same speed control method technique found in many good microcontroller based Line Follower Robot design.

As the result we could get a good precision analog line follower robot that comparable to the microcontroller based Line Follower Robot design. On this tutorial you will also learn many useful information of how to use the operational amplifier.

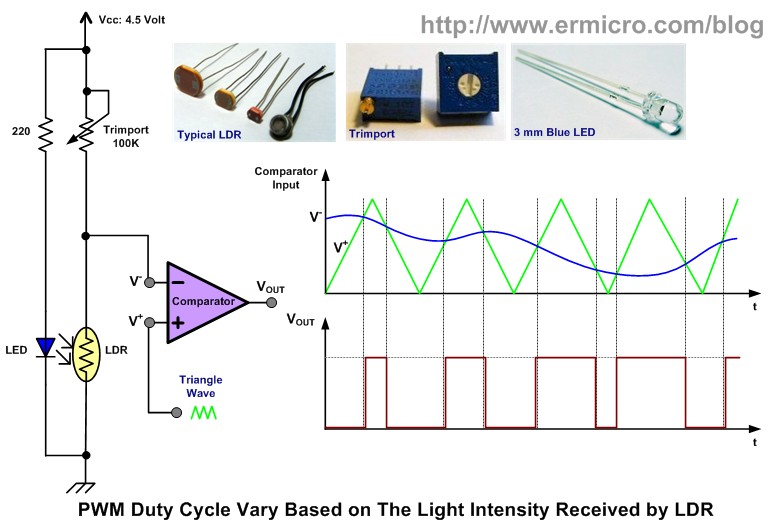

This Line Follower Robot basically use a Cadmium Sulphide (CdS) photocell sensor or known as Light Dependent Resistor (LDR) and the high intensity blue Light Emitting Diode (LED) to illuminate the area under the photocell sensor to sense the black track line and the DC motor speed control technique to navigate the black line track as shown on this following picture: The easy method to navigate the black track line is to turn ON and OFF the left or the right DC motor according to the sensor reading (black turn OFF and white turn ON), but using this method will make the LFR to move in zigzag way. By proportionally control both left and right DC motor speed according to the light intensity level received by the photocell sensor (reflected back by the black track line) we could make the LFR easily navigate this track.

The common technique to control the motor speed efficiently is to use a pulse signal known as the pulse width modulation or PWM for short. PWM basically is an ON and OFF pulse signal with a constant period or frequency. The proportion of pulse ON time to the pulse period is called a duty cycle and it expressed in percentage.

For example if the proportion of pulse ON time is 50% to the total pulse period than we say that the PWM duty cycle is 50%. The PWM duty cycle percentage is corresponding to the average power produced by the pulse signal; the lower percentage produces less power than the higher percentage.

Therefore by changing the PWM duty cycles we could change the average voltage across the DC motor terminals, this mean we could vary the DC motor speed just by changing the PWM duty cycle. Therefore to make the LFR smoothly navigate the black track line, we have to adjust the PWM duty cycle according to the photocell sensor reading.

The brighter light intensity level received by sensor (sensor is on the white surface) will result in higher PWM duty cycle percentage and the darker light intensity level (sensor is on the black line) received by photocell sensor will result in lower PWM duty cycle percentage. By converting each of the photocell sensor light intensity level reading to the corresponding voltage level we could achieve this objective by using what is known as the Voltage Control Pulse Width Modulation principal.

Actually generating the PWM signal is easier with microcontroller instead of discrete components because all you have to do is to program t 🔗 External reference

The schematic for a Line Follower Robot using analog components typically includes the following key elements:

1. **Photocell Sensor and LED**: The CdS photocell sensor is connected in a voltage divider configuration with a resistor. The LED is placed to illuminate the area being sensed, enhancing the contrast between the black track and the white surface.

2. **Operational Amplifier**: An operational amplifier is used to amplify the voltage signal from the photocell. The output of the op-amp is then fed into a comparator circuit that determines the light intensity level.

3. **Motor Driver Circuit**: The outputs from the comparator can control a H-bridge motor driver circuit. The motor driver controls the direction and speed of the DC motors based on the PWM signal generated from the op-amp output.

4. **PWM Generation**: The PWM signal can be generated using a 555 timer IC configured in astable mode. The duty cycle of the PWM signal can be modulated based on the op-amp output, which corresponds to the light intensity detected by the photocell.

5. **DC Motors**: Two DC motors are used for movement, with their speeds controlled by the PWM signals. The motors are connected to the H-bridge, allowing for bidirectional control.

6. **Power Supply**: A suitable power supply is required to power the motors and the control circuitry. Voltage regulators may be employed to ensure that the op-amp and other components receive the appropriate voltage levels.

The overall design aims to achieve responsive and smooth navigation along the track, minimizing zigzag movements through proportional speed adjustments based on sensor feedback. Proper calibration and tuning of the components will enhance the performance of the LFR, making it an effective educational project for beginners in robotics and electronics.Designing a simple and yet functional Line Follower Robot (LFR) is always a fascinating and challenging subject to be learned, the LFR actually could be implemented in many ways start from a simple two transistors to a sophisticated PID (Proportional, Integrate and Differential) which take advantage of the programmable feature of microcontroller t o calculate the PID equation to successfully navigate the black track line on a white background surface. Designing a non microcontroller based LFR is quite challenging tasks as we need to limit the electronic components numbers so the LFR will not too complicated to be built by most average robotics beginners or electronic hobbyists, but at the same time we need to have a good speed control mechanism in order for the LFR to navigate the black track line successfully.

The microcontroller based design LFR in the other hand is a popular choice because it reduces a number of electronic components significantly while still providing a flexible programmable control to the LFR. On this tutorial we are going to build yet another LFR using just the standard analog components easily found on the market but use the same speed control method technique found in many good microcontroller based Line Follower Robot design.

As the result we could get a good precision analog line follower robot that comparable to the microcontroller based Line Follower Robot design. On this tutorial you will also learn many useful information of how to use the operational amplifier.

This Line Follower Robot basically use a Cadmium Sulphide (CdS) photocell sensor or known as Light Dependent Resistor (LDR) and the high intensity blue Light Emitting Diode (LED) to illuminate the area under the photocell sensor to sense the black track line and the DC motor speed control technique to navigate the black line track as shown on this following picture: The easy method to navigate the black track line is to turn ON and OFF the left or the right DC motor according to the sensor reading (black turn OFF and white turn ON), but using this method will make the LFR to move in zigzag way. By proportionally control both left and right DC motor speed according to the light intensity level received by the photocell sensor (reflected back by the black track line) we could make the LFR easily navigate this track.

The common technique to control the motor speed efficiently is to use a pulse signal known as the pulse width modulation or PWM for short. PWM basically is an ON and OFF pulse signal with a constant period or frequency. The proportion of pulse ON time to the pulse period is called a duty cycle and it expressed in percentage.

For example if the proportion of pulse ON time is 50% to the total pulse period than we say that the PWM duty cycle is 50%. The PWM duty cycle percentage is corresponding to the average power produced by the pulse signal; the lower percentage produces less power than the higher percentage.

Therefore by changing the PWM duty cycles we could change the average voltage across the DC motor terminals, this mean we could vary the DC motor speed just by changing the PWM duty cycle. Therefore to make the LFR smoothly navigate the black track line, we have to adjust the PWM duty cycle according to the photocell sensor reading.

The brighter light intensity level received by sensor (sensor is on the white surface) will result in higher PWM duty cycle percentage and the darker light intensity level (sensor is on the black line) received by photocell sensor will result in lower PWM duty cycle percentage. By converting each of the photocell sensor light intensity level reading to the corresponding voltage level we could achieve this objective by using what is known as the Voltage Control Pulse Width Modulation principal.

Actually generating the PWM signal is easier with microcontroller instead of discrete components because all you have to do is to program t 🔗 External reference