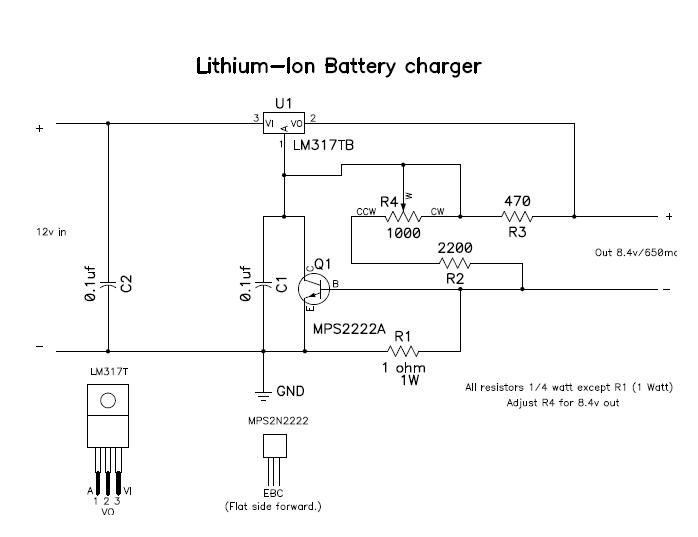

Lithium charger

This project is essential for situations where there is an extra mobile battery available or when there is a need to charge lithium, lithium-ion, or lithium polymer batteries. Maximum capacity...

This project involves the design and implementation of a battery charging circuit specifically tailored for lithium-based batteries. The charging circuit is crucial for safely managing the charging process, ensuring that the batteries are charged efficiently without exceeding their maximum voltage limits, which can lead to battery damage or safety hazards.

The circuit typically incorporates a dedicated lithium battery charger IC, which is responsible for controlling the charging process. Commonly used ICs for this purpose include the TP4056 or the MCP73831. These ICs are designed to provide a constant current/constant voltage (CC/CV) charging profile, which is essential for lithium batteries.

The circuit configuration generally includes the following components:

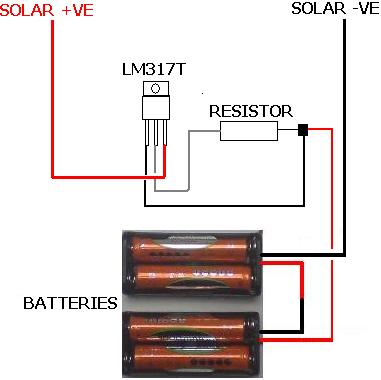

1. **Power Source**: A micro USB connector or other suitable power input to provide the necessary voltage and current for charging. The input voltage should be in the range of 5V, which is standard for USB charging.

2. **Charger IC**: The selected charger IC should be connected to the power source and the lithium battery. The IC will manage the charging cycle, ensuring that the battery receives the correct voltage and current.

3. **Current Limiting Resistor**: A resistor may be included in series with the battery to limit the charging current, protecting the battery from excessive current flow.

4. **Protection Circuitry**: It is advisable to include over-voltage, over-current, and thermal protection circuits. These may consist of MOSFETs, fuses, or dedicated protection ICs, which will disconnect the battery from the circuit in case of unsafe conditions.

5. **LED Indicators**: Optional LED indicators can be integrated to provide visual feedback on the charging status. Typically, a red LED may indicate charging, while a green LED signifies that the battery is fully charged.

6. **Capacitors**: Bypass capacitors are often placed near the power input and the charger IC to filter out noise and stabilize the voltage levels.

The layout of the circuit should be designed to minimize the length of the connections to reduce resistance and inductance, which can affect charging performance. Proper thermal management should also be considered, as the charger IC may generate heat during operation.

Overall, this project serves as a practical solution for charging lithium-based batteries safely and effectively, making it an invaluable addition to any electronics toolkit.You will need this project when you have an extra mobile battery or you need to charge any lithium, Lithium ion or Lithium Polymer battery. Maximum c.. 🔗 External reference

This project involves the design and implementation of a battery charging circuit specifically tailored for lithium-based batteries. The charging circuit is crucial for safely managing the charging process, ensuring that the batteries are charged efficiently without exceeding their maximum voltage limits, which can lead to battery damage or safety hazards.

The circuit typically incorporates a dedicated lithium battery charger IC, which is responsible for controlling the charging process. Commonly used ICs for this purpose include the TP4056 or the MCP73831. These ICs are designed to provide a constant current/constant voltage (CC/CV) charging profile, which is essential for lithium batteries.

The circuit configuration generally includes the following components:

1. **Power Source**: A micro USB connector or other suitable power input to provide the necessary voltage and current for charging. The input voltage should be in the range of 5V, which is standard for USB charging.

2. **Charger IC**: The selected charger IC should be connected to the power source and the lithium battery. The IC will manage the charging cycle, ensuring that the battery receives the correct voltage and current.

3. **Current Limiting Resistor**: A resistor may be included in series with the battery to limit the charging current, protecting the battery from excessive current flow.

4. **Protection Circuitry**: It is advisable to include over-voltage, over-current, and thermal protection circuits. These may consist of MOSFETs, fuses, or dedicated protection ICs, which will disconnect the battery from the circuit in case of unsafe conditions.

5. **LED Indicators**: Optional LED indicators can be integrated to provide visual feedback on the charging status. Typically, a red LED may indicate charging, while a green LED signifies that the battery is fully charged.

6. **Capacitors**: Bypass capacitors are often placed near the power input and the charger IC to filter out noise and stabilize the voltage levels.

The layout of the circuit should be designed to minimize the length of the connections to reduce resistance and inductance, which can affect charging performance. Proper thermal management should also be considered, as the charger IC may generate heat during operation.

Overall, this project serves as a practical solution for charging lithium-based batteries safely and effectively, making it an invaluable addition to any electronics toolkit.You will need this project when you have an extra mobile battery or you need to charge any lithium, Lithium ion or Lithium Polymer battery. Maximum c.. 🔗 External reference