Make a Simplest Temperature Indicator Circuit

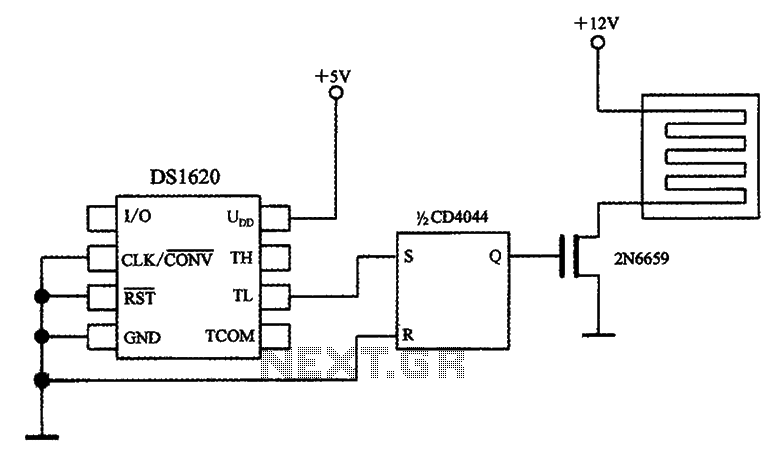

All semiconductors exhibit the tendency to alter their fundamental characteristics in response to changes in ambient temperature. Basic electronic components such as transistors and diodes are particularly susceptible to variations in case temperature. The alteration in their characteristics is typically related to the voltage passing through them, which is directly proportional to the magnitude of the temperature difference surrounding them. Since the diode serves as the reference, it must be situated in an environment with relatively stable temperature conditions; otherwise, the diode will also begin to change its reference level, leading to errors in the indication process. A light-emitting diode (LED) is utilized at the collector of the transistor to visually represent the transistor's conditions, thereby indicating the extent of the temperature variation around the transistor. In this design, the diode is positioned at ambient or room temperature, while the transistor is either placed in or attached to the heat source that requires measurement. Caution must be exercised to ensure that the temperature around the transistor does not exceed 120 degrees Celsius; otherwise, the device may be permanently damaged.

In this electronic circuit design, the primary focus is on monitoring temperature variations using a transistor and diode configuration. The transistor acts as a temperature sensor, where its characteristics change with temperature variations. Specifically, the circuit is designed to measure the temperature of a heat source, with the diode serving as a reference point for ambient temperature. This configuration is crucial for maintaining accuracy in temperature readings.

The LED at the collector of the transistor provides a visual indication of the transistor's state, which correlates with temperature changes. The brightness of the LED varies with the voltage output from the transistor, which is influenced by the temperature difference between the diode and the heat source. This enables users to quickly assess temperature fluctuations in real-time.

To ensure the reliability of the circuit, it is essential to maintain the diode in a stable temperature environment. This can be achieved by placing it away from heat sources and ensuring proper thermal insulation. Additionally, the circuit design must incorporate protective measures to prevent the transistor from exceeding its maximum operating temperature of 120 degrees Celsius. This can include thermal cut-off mechanisms or heat sinks to dissipate excess heat effectively.

Overall, this temperature measurement circuit exemplifies the principles of semiconductor behavior under varying thermal conditions and provides a straightforward method for monitoring temperature through visual indicators.As we know that all semiconductors have this bad habit of changing its basic characteristics in response to ambient temperature changes. Especially basic electronic components like transistors and diodes are very much prone to their case temperature variations.

The change with their characteristics with these devices is typically in terms of th e passage of voltage through them, which is directly proportional with the magnitude of the temperature difference surrounding them. Obviously since the diode is placed as the reference, it has to be placed in an environment with relatively consistent temperature conditions, otherwise the diode will also start changing its reference level causing error in the indication process.

A LED is used here at the collector of the transistor, which directly interprets the transistor conditions and therefore helps to show how much temperature difference is taking place around the transistor. In this design the diode is placed at the ambient temperature or at the room temperature which the transistor is placed or attached to the heat source which needs to be measured.

Caution must be maintained, not to exceed the temperature over the transistor above 120 degree Celsius, other wise the device may get burnt and damaged permanently. 🔗 External reference

In this electronic circuit design, the primary focus is on monitoring temperature variations using a transistor and diode configuration. The transistor acts as a temperature sensor, where its characteristics change with temperature variations. Specifically, the circuit is designed to measure the temperature of a heat source, with the diode serving as a reference point for ambient temperature. This configuration is crucial for maintaining accuracy in temperature readings.

The LED at the collector of the transistor provides a visual indication of the transistor's state, which correlates with temperature changes. The brightness of the LED varies with the voltage output from the transistor, which is influenced by the temperature difference between the diode and the heat source. This enables users to quickly assess temperature fluctuations in real-time.

To ensure the reliability of the circuit, it is essential to maintain the diode in a stable temperature environment. This can be achieved by placing it away from heat sources and ensuring proper thermal insulation. Additionally, the circuit design must incorporate protective measures to prevent the transistor from exceeding its maximum operating temperature of 120 degrees Celsius. This can include thermal cut-off mechanisms or heat sinks to dissipate excess heat effectively.

Overall, this temperature measurement circuit exemplifies the principles of semiconductor behavior under varying thermal conditions and provides a straightforward method for monitoring temperature through visual indicators.As we know that all semiconductors have this bad habit of changing its basic characteristics in response to ambient temperature changes. Especially basic electronic components like transistors and diodes are very much prone to their case temperature variations.

The change with their characteristics with these devices is typically in terms of th e passage of voltage through them, which is directly proportional with the magnitude of the temperature difference surrounding them. Obviously since the diode is placed as the reference, it has to be placed in an environment with relatively consistent temperature conditions, otherwise the diode will also start changing its reference level causing error in the indication process.

A LED is used here at the collector of the transistor, which directly interprets the transistor conditions and therefore helps to show how much temperature difference is taking place around the transistor. In this design the diode is placed at the ambient temperature or at the room temperature which the transistor is placed or attached to the heat source which needs to be measured.

Caution must be maintained, not to exceed the temperature over the transistor above 120 degree Celsius, other wise the device may get burnt and damaged permanently. 🔗 External reference