Microprocessor triac array driver

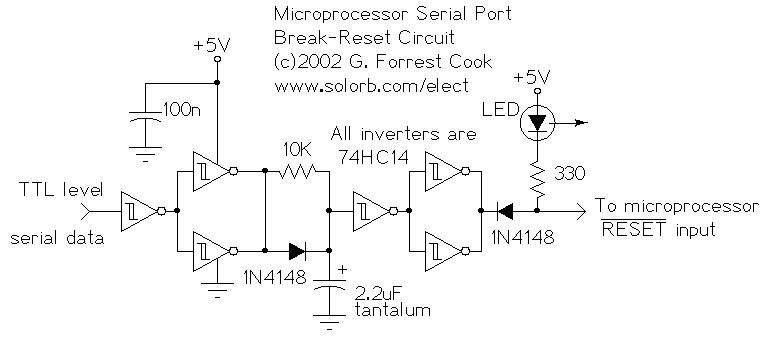

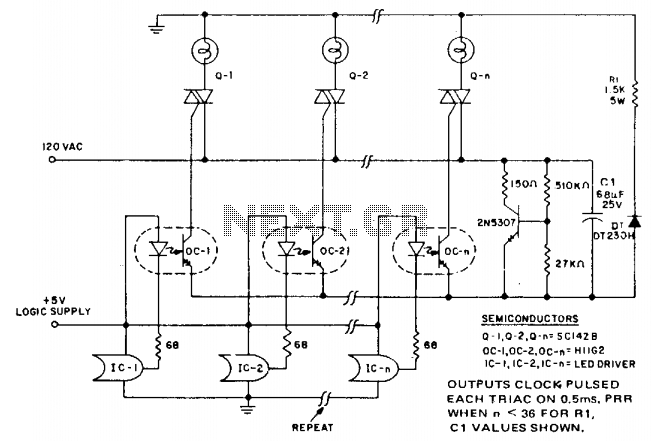

In microprocessor control of multiple loads, minimizing the cost per load is essential. A typical application is a large display that drives arrays of incandescent lamps. This circuit achieves minimal component cost per stage by utilizing optocoupler triggering of triac power switches from logic outputs. Cost efficiency is realized through more complex software in the logic. A Darlington output optocoupler generates gate current pulses for the triac, eliminating the need for a current limiting resistor and benefiting from the low-cost coupler. The trigger current source is a dipped tantalum capacitor, charged from the line through a series resistor, with coarse voltage regulation provided by the Darlington signal transistor. The resistor and capacitor are shared among all the Darlington-triac pairs, resulting in reduced size and cost due to the low duty cycle of pulsing. Coupler IRED current pulses are delivered for the duration of one logic clock pulse (2-10 µsec), at intervals of 0.4 to 1 msec, from an LED driver integrated circuit. The pulse timing is derived from the clock waveform when the logic system requires triac conduction. A current limiting resistor is omitted to prevent the Miller effect from slowing down the H11G2 switching speed, ensuring sufficient current is supplied to trigger the triac. Optodarlington power dissipation is managed through the low duty cycle and the characteristics of the capacitor supply.

The described circuit functions as an efficient control mechanism for multiple loads, particularly in applications where cost and space are critical factors. The use of a microprocessor allows for sophisticated control algorithms, which can optimize the operation of the system while minimizing component costs. The incorporation of optocouplers enables electrical isolation between the control logic and the high-power loads, enhancing safety and reliability.

The Darlington output optocoupler serves a dual purpose; it not only provides the necessary gate current pulses to trigger the triacs but also simplifies the circuit design by eliminating the need for additional components like current limiting resistors. This design choice is particularly advantageous in high-density applications where space is at a premium.

The shared resistor and capacitor configuration allows multiple Darlington-triac pairs to operate efficiently, leveraging the low duty cycle of pulsing to reduce overall component size and cost. The timing of the IRED current pulses is tightly controlled by the logic clock, ensuring that the triacs are only activated when necessary, thus conserving energy and minimizing heat generation.

The absence of a current limiting resistor is a critical design feature that enhances the switching performance of the H11G2 optocoupler. By avoiding the Miller effect, the circuit maintains fast switching speeds, which is essential for reliable triac operation. The careful selection of components, such as the dipped tantalum capacitor, further contributes to the circuit's efficiency and effectiveness in high-power applications.

Overall, this circuit design exemplifies a cost-effective and efficient approach to controlling multiple loads in microprocessor-based systems, particularly suitable for large-scale displays and similar applications.In microprocessor control of multiple loads, the minimum cost per load is critical. A typical application example is a large display involving driving arrays of incandescent lamps. This circuit provides minimal component cost per stage and optocoupler triggering of triac power switches from logic outputs. The minimal component cost is attained by using more complex software in the logic. A darlington output optocoupler provides gate current pulses to the triac, with cost advantages gained from eliminating the current limiting resistor and from the low cost coupler.

The trigger current source is a dipped tantalum capacitor, charged from the line via a series resistor with coarse voltage regulation being provided by the darlington signal transistor. The resistor andxapacitor are shared by all the darlington-triac pairs and are small in size and cost due to the low duty cycle of pulsing. Coupler IRED current pulses are supplied for the duration of one logic clock pulse (2-10 /isec), at 0.4 to 1 msec intervals, from a LED driver I.C.

The pulse timing is derived from the clock waveform when the logic system requires triac conduction. A current limiting resistor is not used, which prevents Miller effect slowdown of the H11G2 switching speed to the extent the triac is supplied insufficient current to trigger. Optodarlington power dissipation is controlled by the low duty cycle and the capacitor supply characteristics.

🔗 External reference

The described circuit functions as an efficient control mechanism for multiple loads, particularly in applications where cost and space are critical factors. The use of a microprocessor allows for sophisticated control algorithms, which can optimize the operation of the system while minimizing component costs. The incorporation of optocouplers enables electrical isolation between the control logic and the high-power loads, enhancing safety and reliability.

The Darlington output optocoupler serves a dual purpose; it not only provides the necessary gate current pulses to trigger the triacs but also simplifies the circuit design by eliminating the need for additional components like current limiting resistors. This design choice is particularly advantageous in high-density applications where space is at a premium.

The shared resistor and capacitor configuration allows multiple Darlington-triac pairs to operate efficiently, leveraging the low duty cycle of pulsing to reduce overall component size and cost. The timing of the IRED current pulses is tightly controlled by the logic clock, ensuring that the triacs are only activated when necessary, thus conserving energy and minimizing heat generation.

The absence of a current limiting resistor is a critical design feature that enhances the switching performance of the H11G2 optocoupler. By avoiding the Miller effect, the circuit maintains fast switching speeds, which is essential for reliable triac operation. The careful selection of components, such as the dipped tantalum capacitor, further contributes to the circuit's efficiency and effectiveness in high-power applications.

Overall, this circuit design exemplifies a cost-effective and efficient approach to controlling multiple loads in microprocessor-based systems, particularly suitable for large-scale displays and similar applications.In microprocessor control of multiple loads, the minimum cost per load is critical. A typical application example is a large display involving driving arrays of incandescent lamps. This circuit provides minimal component cost per stage and optocoupler triggering of triac power switches from logic outputs. The minimal component cost is attained by using more complex software in the logic. A darlington output optocoupler provides gate current pulses to the triac, with cost advantages gained from eliminating the current limiting resistor and from the low cost coupler.

The trigger current source is a dipped tantalum capacitor, charged from the line via a series resistor with coarse voltage regulation being provided by the darlington signal transistor. The resistor andxapacitor are shared by all the darlington-triac pairs and are small in size and cost due to the low duty cycle of pulsing. Coupler IRED current pulses are supplied for the duration of one logic clock pulse (2-10 /isec), at 0.4 to 1 msec intervals, from a LED driver I.C.

The pulse timing is derived from the clock waveform when the logic system requires triac conduction. A current limiting resistor is not used, which prevents Miller effect slowdown of the H11G2 switching speed to the extent the triac is supplied insufficient current to trigger. Optodarlington power dissipation is controlled by the low duty cycle and the capacitor supply characteristics.

🔗 External reference