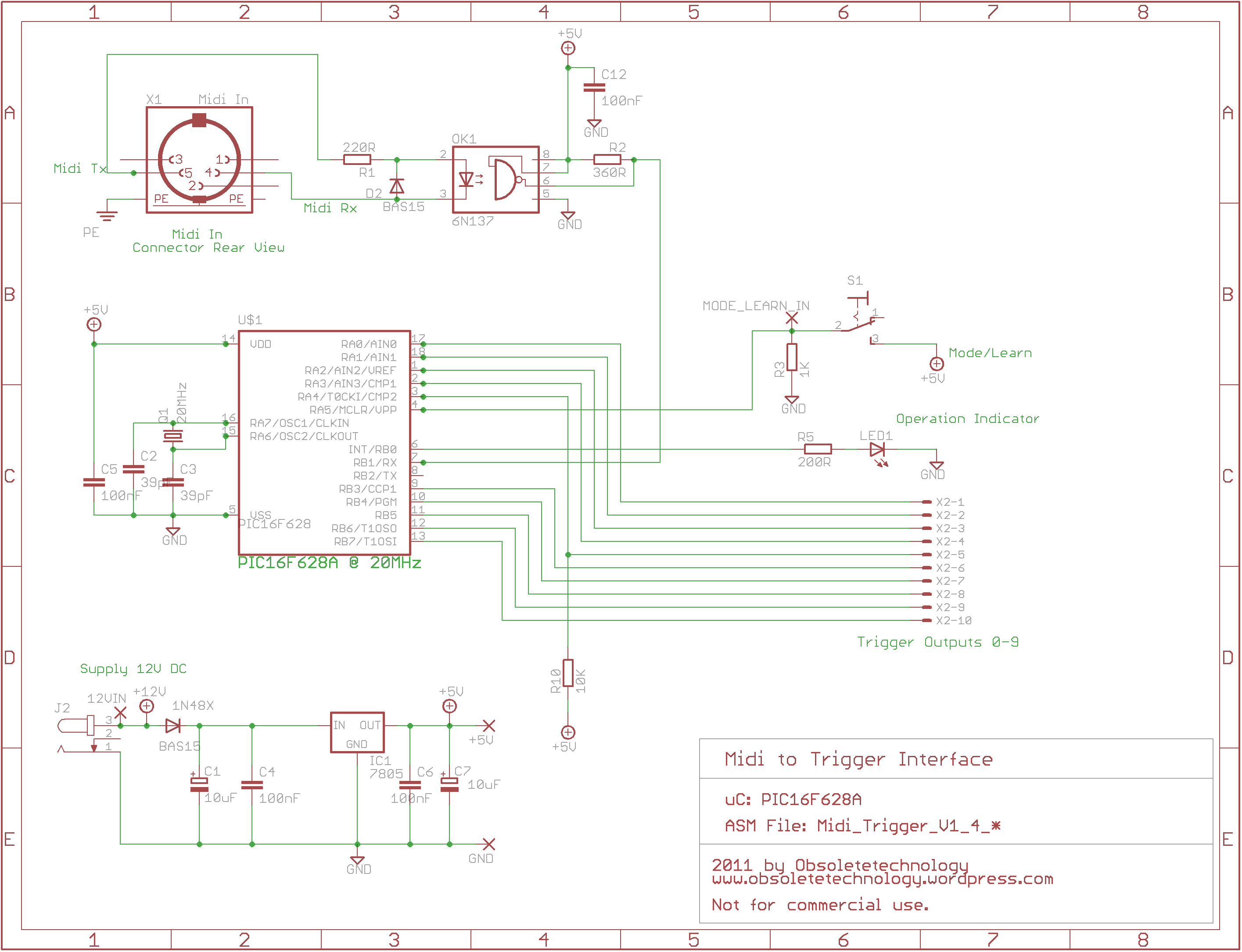

MIDI Drum Machine Schematic Main CPU Section

The 82C55 and seven-segment decoders on the display board will be replaced with a set of shift registers to eliminate the need for the 82C55 and the extensive wiring. The ADC0804 will be substituted with a serial interface ADC chip, and the 8051 will be upgraded to an 89C51, which will render the 27C16, 74HC373, and 74HC138 unnecessary. The primary objective is to significantly reduce the number of wires, allowing individuals attempting to construct the design without a printed circuit board to manage fewer interconnections. Consequently, wiring errors will likely affect only a portion of the drum machine, rather than causing a complete failure with no feasible troubleshooting options. The new board will require only a single 5-volt power supply and will utilize a cost-effective EEPROM chip instead of a battery backup.

The proposed design modification focuses on enhancing the reliability and simplicity of the drum machine's electronic architecture. By replacing the 82C55 and seven-segment decoders with shift registers, the circuit not only minimizes the component count but also streamlines the signal routing. Shift registers can efficiently manage multiple output signals while reducing the complexity associated with parallel data transmission.

The substitution of the ADC0804 with a serial interface ADC chip introduces a more efficient data acquisition method. Serial ADCs typically require fewer pins and can simplify the communication protocol, which is particularly beneficial in designs where space and component count are critical. The 89C51 microcontroller, being a more advanced version of the 8051, offers improved performance and additional features that can enhance the overall functionality of the drum machine.

Eliminating components such as the 27C16 EPROM, 74HC373 latch, and 74HC138 decoder not only reduces the physical size of the circuit but also minimizes potential points of failure. This reduction in complexity is crucial for users who may not have access to a printed circuit board, as it allows for easier assembly and troubleshooting. By ensuring that wiring errors affect only a specific section of the device, the design promotes a more user-friendly experience, allowing for quicker identification and resolution of issues.

The decision to power the entire board with a single 5-volt supply simplifies the power management requirements, making the system more accessible and cost-effective. The integration of an EEPROM chip instead of a battery backup further enhances reliability and reduces maintenance concerns, as EEPROMs can retain data without the need for a continuous power source. Overall, these modifications aim to create a more robust, efficient, and user-friendly electronic design for the drum machine.The 82C55 and 7 segment decoders on the display board will be changed to a group of shift registers on the display board, so that the 82C55 and the large number of wires won`t be needed. The ADC0804 will be replaced with a serial interface ADC chip, and the 8051 will be replaced with a 89C51, so that the 27C16, 74HC373 and 74HC138 won`t be needed.

The main idea is to greatly reduce the number of wires, so that people who attempt to build the design without a printed circuit board will have far fewer wires to interconnect, and most wiring errors will result in only a portion of the drum machine not working, instead of having the entire thing dead and no reasonable way to troubleshoot. The new board will also only require a single 5 volt supply and will use an inexpensive EEPROM chip instead of battery backup.

🔗 External reference

The proposed design modification focuses on enhancing the reliability and simplicity of the drum machine's electronic architecture. By replacing the 82C55 and seven-segment decoders with shift registers, the circuit not only minimizes the component count but also streamlines the signal routing. Shift registers can efficiently manage multiple output signals while reducing the complexity associated with parallel data transmission.

The substitution of the ADC0804 with a serial interface ADC chip introduces a more efficient data acquisition method. Serial ADCs typically require fewer pins and can simplify the communication protocol, which is particularly beneficial in designs where space and component count are critical. The 89C51 microcontroller, being a more advanced version of the 8051, offers improved performance and additional features that can enhance the overall functionality of the drum machine.

Eliminating components such as the 27C16 EPROM, 74HC373 latch, and 74HC138 decoder not only reduces the physical size of the circuit but also minimizes potential points of failure. This reduction in complexity is crucial for users who may not have access to a printed circuit board, as it allows for easier assembly and troubleshooting. By ensuring that wiring errors affect only a specific section of the device, the design promotes a more user-friendly experience, allowing for quicker identification and resolution of issues.

The decision to power the entire board with a single 5-volt supply simplifies the power management requirements, making the system more accessible and cost-effective. The integration of an EEPROM chip instead of a battery backup further enhances reliability and reduces maintenance concerns, as EEPROMs can retain data without the need for a continuous power source. Overall, these modifications aim to create a more robust, efficient, and user-friendly electronic design for the drum machine.The 82C55 and 7 segment decoders on the display board will be changed to a group of shift registers on the display board, so that the 82C55 and the large number of wires won`t be needed. The ADC0804 will be replaced with a serial interface ADC chip, and the 8051 will be replaced with a 89C51, so that the 27C16, 74HC373 and 74HC138 won`t be needed.

The main idea is to greatly reduce the number of wires, so that people who attempt to build the design without a printed circuit board will have far fewer wires to interconnect, and most wiring errors will result in only a portion of the drum machine not working, instead of having the entire thing dead and no reasonable way to troubleshoot. The new board will also only require a single 5 volt supply and will use an inexpensive EEPROM chip instead of battery backup.

🔗 External reference