MIDI Sync Box

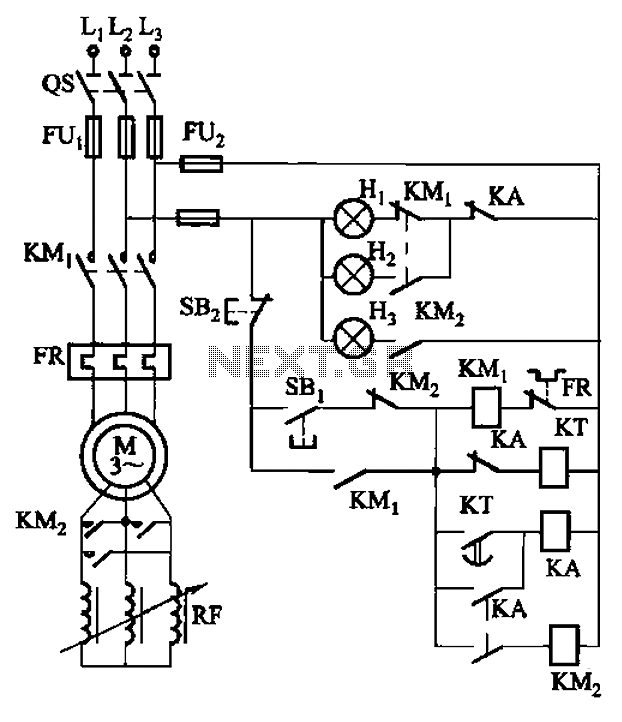

All components function correctly. The final software comprises 930 lines of assembler code. ProTel was utilized to create the final circuit diagram. The design has been streamlined to a single chip, with the PIC microcontroller performing all tasks. It directly drives the LED and MIDI output. Multiplexing is employed to control the seven-segment display and read inputs. The PIC’s built-in timer maintains accurate operation. An upgrade was made to a Duron 900 PC running Windows 2000, which has proven stable compared to Windows 98. However, Windows 2000 does not support the NOPPP software previously used for downloading code to the PIC. The Linux version of NOPPP is functioning well, along with gpasm, a free PIC compiler. The design has been revised to eliminate the buffer chip, allowing the PIC to directly drive the MIDI output. A 7-bit bus arrangement is used for sharing I/O pins between the inputs and LED display. An issue arose with the large red illuminated push button requiring 12 volts, while the system operates at 5 volts. An adapter was created using veroboard to substitute an LED. The brightness of modern LEDs was noted. Understanding MIDI signals presented challenges due to limited documentation. Trial-and-error, along with a CRO, were used to analyze signals from MIDI equipment. MIDI operates on current rather than voltage, with the receiving end having a 1k input impedance and the sender expected to generate a 5V differential, producing a 5mA current. Current flow indicates a logic 0, while no current signifies a logic 1. The idle state exhibits no current flow. A common MIDI output configuration involves connecting pin 4 of the DIN plug to 5V and pin 5 to the digital output, forming a hardware inverter for standard logic levels. The serial data transmission method was also confusing; although it was described as having 1 start bit, 8 data bits, and 1 stop bit, it differs from RS-232. The start bit in MIDI is a 0, the stop bit is a 1, and data bits are transmitted in reverse order. The firmware development is ongoing, with the program currently at 600 lines and further work remaining. An issue was identified with the potentiometer voltage ramp arrangement, which proved inaccurate due to variations in voltage, temperature, and current. Consequently, a rotary encoder was selected as a more suitable alternative, functioning as a binary counter with detents to maintain position stability.

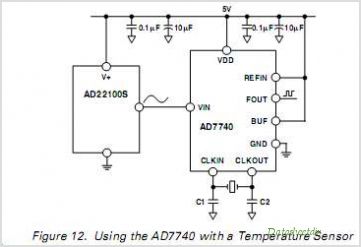

The circuit design incorporates a PIC microcontroller that serves as the central control unit, responsible for managing multiple functionalities including LED driving, MIDI output, and input reading through multiplexing. The choice of a PIC microcontroller allows for efficient processing and control due to its integrated timer and I/O capabilities. The use of multiplexing enables the microcontroller to manage the seven-segment display while simultaneously reading multiple inputs, optimizing the use of available I/O pins.

The MIDI output is configured to operate based on current rather than voltage, which necessitates careful consideration of the output configuration. Connecting pin 4 of the DIN connector to 5V and pin 5 to the microcontroller output creates an inverter setup, allowing for compatibility with standard logic levels. This configuration ensures that the microcontroller can effectively communicate MIDI signals, which are characterized by their unique start, stop, and data bit arrangements.

The integration of a rotary encoder as a control input enhances the system's usability, providing precise feedback and eliminating the inaccuracies associated with potentiometer-based voltage readings. The rotary encoder's binary counting mechanism, combined with its detent feature, allows for reliable and consistent input, making it an ideal choice for applications requiring precise adjustments.

The firmware development process continues to evolve, with ongoing revisions and improvements being made to enhance functionality and performance. The complexity of the software, along with the challenges encountered in understanding and implementing MIDI communication protocols, reflects the intricate nature of electronic design and programming. Overall, the project demonstrates a successful integration of hardware and software components, resulting in a robust and efficient electronic system.Everything works just great. The final software is 930 lines of assembler. I also learnt how to use ProTel so I could draw up the final circuit properly. Here`s the result. Notice that I`ve got it down to just one chip now, the little PIC is doing everything. It can directly drive the LED and the MIDI output. I`ve used multiplexing to enable it to drive the 7 segment display and read all the inputs. The PIC`s built in timer keeps everything running accurately, all in all, I`m very pleased with the result. Since I last did any work on this project, I have upgraded my PC to a Duron 900 and have installed Windows 2000. I am most impressed with the stability of Win2K, I rarely have more than two crashes per week as opposed to about three times a day under Win98.

However, Windows 2000 will not run the NOPPP software which I have been using to download code into the PIC. I suspect the way ports are accessed in Win2K is not backward compatible with Win95. To cut a long story short, I have found the Linux version of NOPPP works just fine so I`m using that instead.

gpasm is a free compiler for the PIC which runs on Linux so I`m all set to continue development without using Windows. I`ve redesigned the thing again and got rid of the buffer chip. I`m driving the MIDI output directly from the PIC and it works fine. I`ve used a 7 bit bus arrangement to allow all the inputs to share the same I/O pins as the LED display.

One little hitch was the discovery that the big red illuminated push button needs 12 volts to light up. But I`m running everything off 5 volts. So I`ve made a little adapter out of a small piece of veroboard so I can substitute a LED. I tellya these modern LEDs are so bright! I nearly blinded myself messing about with it. One thing I had a lot of trouble with was understanding the MIDI signals. I couldn`t seem to find much documentation on them. I had to do a lot of trial-and-error and also use my CRO to analyse the signals coming out of some MIDI equipment.

Here`s what I found: MIDI works by current, not voltage. The receiving end has a 1k input impedance and the sender is expected to put a 5V voltage differential across this which produces a current of 5mA. Current flow is indicative of a logic 0. No current flow is a logic 1. There is no current flow when the line is idle. A fairly standard way to implement a MIDI output is to tie pin 4 of the DIN plug to 5V and pin 5 to your digital output.

This forms a hardware inverter so you can use normal logic levels in your circuit. Another confusing thing is that nowhere is it described how the serial data is sent. The literature will tell you that there is 1 start bit, 8 data bits and one stop bit. Great, just like RS-232 I thought. Well no, it`s not anything like RS-232. The start bit in MIDI is a 0, the stop bit is a 1 and the data bits are sent in reverse order. All perfectly fine but I had to discover this myself. I`m steadily building the firmware for this thing. Something that sounds simple is turning out to be a little more complex than I thought, still, that`s pretty normal in the software world. My program is around 600 lines and I`ve still got a lot of stuff left to do. Another problem I`ve come across is the Potentiometer voltage ramp arrangement has turned out to be not very accurate, the reading varies wildly depending on voltage, temperature, current and just about any other variable you can think of.

After wasting a lot of time with it, I`ve decided it`s just not a suitable method for setting the speed. So instead, I`ve got myself a rotary encoder. This looks like a potentiometer but it`s actually a binary counter which increments as you turn it. It has detents so it won`t drift once you turn it to a specific position and is generally much more suitable for this role.

Now it`s time to move back i 🔗 External reference

The circuit design incorporates a PIC microcontroller that serves as the central control unit, responsible for managing multiple functionalities including LED driving, MIDI output, and input reading through multiplexing. The choice of a PIC microcontroller allows for efficient processing and control due to its integrated timer and I/O capabilities. The use of multiplexing enables the microcontroller to manage the seven-segment display while simultaneously reading multiple inputs, optimizing the use of available I/O pins.

The MIDI output is configured to operate based on current rather than voltage, which necessitates careful consideration of the output configuration. Connecting pin 4 of the DIN connector to 5V and pin 5 to the microcontroller output creates an inverter setup, allowing for compatibility with standard logic levels. This configuration ensures that the microcontroller can effectively communicate MIDI signals, which are characterized by their unique start, stop, and data bit arrangements.

The integration of a rotary encoder as a control input enhances the system's usability, providing precise feedback and eliminating the inaccuracies associated with potentiometer-based voltage readings. The rotary encoder's binary counting mechanism, combined with its detent feature, allows for reliable and consistent input, making it an ideal choice for applications requiring precise adjustments.

The firmware development process continues to evolve, with ongoing revisions and improvements being made to enhance functionality and performance. The complexity of the software, along with the challenges encountered in understanding and implementing MIDI communication protocols, reflects the intricate nature of electronic design and programming. Overall, the project demonstrates a successful integration of hardware and software components, resulting in a robust and efficient electronic system.Everything works just great. The final software is 930 lines of assembler. I also learnt how to use ProTel so I could draw up the final circuit properly. Here`s the result. Notice that I`ve got it down to just one chip now, the little PIC is doing everything. It can directly drive the LED and the MIDI output. I`ve used multiplexing to enable it to drive the 7 segment display and read all the inputs. The PIC`s built in timer keeps everything running accurately, all in all, I`m very pleased with the result. Since I last did any work on this project, I have upgraded my PC to a Duron 900 and have installed Windows 2000. I am most impressed with the stability of Win2K, I rarely have more than two crashes per week as opposed to about three times a day under Win98.

However, Windows 2000 will not run the NOPPP software which I have been using to download code into the PIC. I suspect the way ports are accessed in Win2K is not backward compatible with Win95. To cut a long story short, I have found the Linux version of NOPPP works just fine so I`m using that instead.

gpasm is a free compiler for the PIC which runs on Linux so I`m all set to continue development without using Windows. I`ve redesigned the thing again and got rid of the buffer chip. I`m driving the MIDI output directly from the PIC and it works fine. I`ve used a 7 bit bus arrangement to allow all the inputs to share the same I/O pins as the LED display.

One little hitch was the discovery that the big red illuminated push button needs 12 volts to light up. But I`m running everything off 5 volts. So I`ve made a little adapter out of a small piece of veroboard so I can substitute a LED. I tellya these modern LEDs are so bright! I nearly blinded myself messing about with it. One thing I had a lot of trouble with was understanding the MIDI signals. I couldn`t seem to find much documentation on them. I had to do a lot of trial-and-error and also use my CRO to analyse the signals coming out of some MIDI equipment.

Here`s what I found: MIDI works by current, not voltage. The receiving end has a 1k input impedance and the sender is expected to put a 5V voltage differential across this which produces a current of 5mA. Current flow is indicative of a logic 0. No current flow is a logic 1. There is no current flow when the line is idle. A fairly standard way to implement a MIDI output is to tie pin 4 of the DIN plug to 5V and pin 5 to your digital output.

This forms a hardware inverter so you can use normal logic levels in your circuit. Another confusing thing is that nowhere is it described how the serial data is sent. The literature will tell you that there is 1 start bit, 8 data bits and one stop bit. Great, just like RS-232 I thought. Well no, it`s not anything like RS-232. The start bit in MIDI is a 0, the stop bit is a 1 and the data bits are sent in reverse order. All perfectly fine but I had to discover this myself. I`m steadily building the firmware for this thing. Something that sounds simple is turning out to be a little more complex than I thought, still, that`s pretty normal in the software world. My program is around 600 lines and I`ve still got a lot of stuff left to do. Another problem I`ve come across is the Potentiometer voltage ramp arrangement has turned out to be not very accurate, the reading varies wildly depending on voltage, temperature, current and just about any other variable you can think of.

After wasting a lot of time with it, I`ve decided it`s just not a suitable method for setting the speed. So instead, I`ve got myself a rotary encoder. This looks like a potentiometer but it`s actually a binary counter which increments as you turn it. It has detents so it won`t drift once you turn it to a specific position and is generally much more suitable for this role.

Now it`s time to move back i 🔗 External reference