motor timer

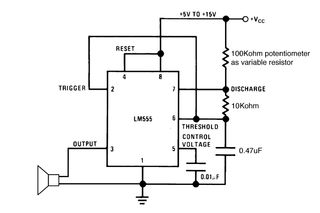

The primary concept is to rotate the motor slightly every 15 seconds. A monofilament line conveys the motion to the ornament, which is wound by the motor and gradually unwinds as the ornament turns. The charging circuit includes a 1 megohm resistor, and when combined with a 22 microfarad capacitor, it produces a time constant of approximately 22 seconds. The formula for the 555 timer indicates a factor of about 0.5 on the timing, resulting in roughly 11 seconds. The discharge circuit utilizes a 10 kilohm resistor, leading to a time constant of about one-fifth of a second. During the discharge phase, the output pin of the 555 timer is low, which activates the motor. This configuration capitalizes on the 555 timer's ability to sink more current than it can source. Additionally, fewer components are required to achieve a duty cycle of less than 50 percent. The TLC555, a low-power variant of the classic 555, is recommended for its reliable operation at 3 volts and minimal power supply glitches. The circuit can be powered by two AA batteries or a 9-volt battery, depending on the motor's specifications. The 555 timer can operate within a voltage range of 3 to 18 volts without affecting timing. There were issues with the ornament's weight potentially increasing friction, which may have limited the current supplied to the motor and reduced torque. A potential solution could be to bypass the diode or add another battery, although space constraints in the housing made this challenging. The circuit layout is suitable for implementation on a perf board, utilizing the leads of the capacitor and resistor for connecting additional wires for battery and motor connections.

The described circuit utilizes a 555 timer in astable mode to control the operation of a small motor, which is responsible for rotating an ornament. The motor's rotation is transmitted through a monofilament line, creating a visually appealing effect as the ornament unwinds. The circuit's timing is primarily determined by the combination of the 1 megohm resistor and the 22 microfarad capacitor, which establishes a long charging time constant. This results in a delay of approximately 22 seconds for the motor to receive power, while the 555 timer's inherent characteristics reduce this to about 11 seconds for the output pulse duration.

The discharge path, governed by the 10 kilohm resistor, allows for quick discharging of the capacitor, thus enabling rapid activation of the motor. The choice of the TLC555 timer is advantageous due to its low power consumption and compatibility with lower voltage supplies, making it ideal for battery-operated applications. It is important to maintain a bypass capacitor in the circuit to ensure stable voltage levels and prevent glitches during operation, which can occur due to the internal switching of the timer.

The motor's performance may be influenced by the weight of the ornament, introducing friction that could hinder rotation. This aspect highlights the significance of ensuring that the power supplied to the motor is sufficient to overcome such mechanical resistance. If the current limitation is suspected to be the cause of reduced torque, adjustments such as modifying the circuit to eliminate unnecessary components, like a diode, or exploring alternate power sources could enhance performance.

The overall design is compact, allowing for assembly on perf board, where the leads from the capacitor and resistor serve as convenient points for connecting the motor and battery. This facilitates a straightforward construction process while ensuring that the circuit remains functional and efficient. Proper attention to component values and layout will lead to a reliable and effective motor control system for the ornament.The basic idea is to turn the motor just a little bit every 15 seconds or so. A monofilament line transmits the motion to the ornament. It gets wound by the motor and slowly unwinds by turning the ornament. The charging path has a 1 megohm resistor in it, which combined with the 22 microfarad capacitor, yields a time constant of about 22 seconds. The formula for the 555 timer has a factor of about 0. 5 on the time, so it comes out to around 11 seconds. The discharge path is through a 10 kilohm resistor, so its time constant is around a fifth of a second. During the discharge portion of the cycle, the 555 output pin is low; this is used to activate the motor.

Doing it this way takes advantage of the fact that the 555 can sink quite a bit more current than it can source (but read on, this didn`t work as we expected). In addition, it takes fewer components to implement a < 50 percent duty cycle. Use Google to search for 555 timer. We suggest using a TLC555 - it`s a low power version of the classic 555 and it runs reliably at 3 volts.

It also doesn`t glitch the power supply as badly as other kinds of 555 chips, which can happen when the internal flip-flop triggers. We tried skipping the bypass capacitor, but it didn`t work, so you`ll still need that. This circuit can be used with two AA batteries, or a 9 volt battery. It depends on the motor`s specifications. The 555 will accept anything from 3 to 18 volts; the timing won`t change. (But don`t panic! We found an answer. Read on. ) The weight of the ornament was probably increasing the friction. The theory is that the low power 555 was limiting the current to the motor, resulting in a loss of torque: completely shorting out the output to ground would let the motor work.

A simple fix might be to skip the diode or add another battery. Unfortunately we didn`t have room in the housing for another battery, so this began to appear to be a failed project. The layout can be used to build the timer on a piece of perf board. We used the leads on the big cap and the megohm resistor as a handy way to attach the extra wires needed for the battery and motor connections.

🔗 External reference

The described circuit utilizes a 555 timer in astable mode to control the operation of a small motor, which is responsible for rotating an ornament. The motor's rotation is transmitted through a monofilament line, creating a visually appealing effect as the ornament unwinds. The circuit's timing is primarily determined by the combination of the 1 megohm resistor and the 22 microfarad capacitor, which establishes a long charging time constant. This results in a delay of approximately 22 seconds for the motor to receive power, while the 555 timer's inherent characteristics reduce this to about 11 seconds for the output pulse duration.

The discharge path, governed by the 10 kilohm resistor, allows for quick discharging of the capacitor, thus enabling rapid activation of the motor. The choice of the TLC555 timer is advantageous due to its low power consumption and compatibility with lower voltage supplies, making it ideal for battery-operated applications. It is important to maintain a bypass capacitor in the circuit to ensure stable voltage levels and prevent glitches during operation, which can occur due to the internal switching of the timer.

The motor's performance may be influenced by the weight of the ornament, introducing friction that could hinder rotation. This aspect highlights the significance of ensuring that the power supplied to the motor is sufficient to overcome such mechanical resistance. If the current limitation is suspected to be the cause of reduced torque, adjustments such as modifying the circuit to eliminate unnecessary components, like a diode, or exploring alternate power sources could enhance performance.

The overall design is compact, allowing for assembly on perf board, where the leads from the capacitor and resistor serve as convenient points for connecting the motor and battery. This facilitates a straightforward construction process while ensuring that the circuit remains functional and efficient. Proper attention to component values and layout will lead to a reliable and effective motor control system for the ornament.The basic idea is to turn the motor just a little bit every 15 seconds or so. A monofilament line transmits the motion to the ornament. It gets wound by the motor and slowly unwinds by turning the ornament. The charging path has a 1 megohm resistor in it, which combined with the 22 microfarad capacitor, yields a time constant of about 22 seconds. The formula for the 555 timer has a factor of about 0. 5 on the time, so it comes out to around 11 seconds. The discharge path is through a 10 kilohm resistor, so its time constant is around a fifth of a second. During the discharge portion of the cycle, the 555 output pin is low; this is used to activate the motor.

Doing it this way takes advantage of the fact that the 555 can sink quite a bit more current than it can source (but read on, this didn`t work as we expected). In addition, it takes fewer components to implement a < 50 percent duty cycle. Use Google to search for 555 timer. We suggest using a TLC555 - it`s a low power version of the classic 555 and it runs reliably at 3 volts.

It also doesn`t glitch the power supply as badly as other kinds of 555 chips, which can happen when the internal flip-flop triggers. We tried skipping the bypass capacitor, but it didn`t work, so you`ll still need that. This circuit can be used with two AA batteries, or a 9 volt battery. It depends on the motor`s specifications. The 555 will accept anything from 3 to 18 volts; the timing won`t change. (But don`t panic! We found an answer. Read on. ) The weight of the ornament was probably increasing the friction. The theory is that the low power 555 was limiting the current to the motor, resulting in a loss of torque: completely shorting out the output to ground would let the motor work.

A simple fix might be to skip the diode or add another battery. Unfortunately we didn`t have room in the housing for another battery, so this began to appear to be a failed project. The layout can be used to build the timer on a piece of perf board. We used the leads on the big cap and the megohm resistor as a handy way to attach the extra wires needed for the battery and motor connections.

🔗 External reference