NTC phase asynchronous motor protection circuit

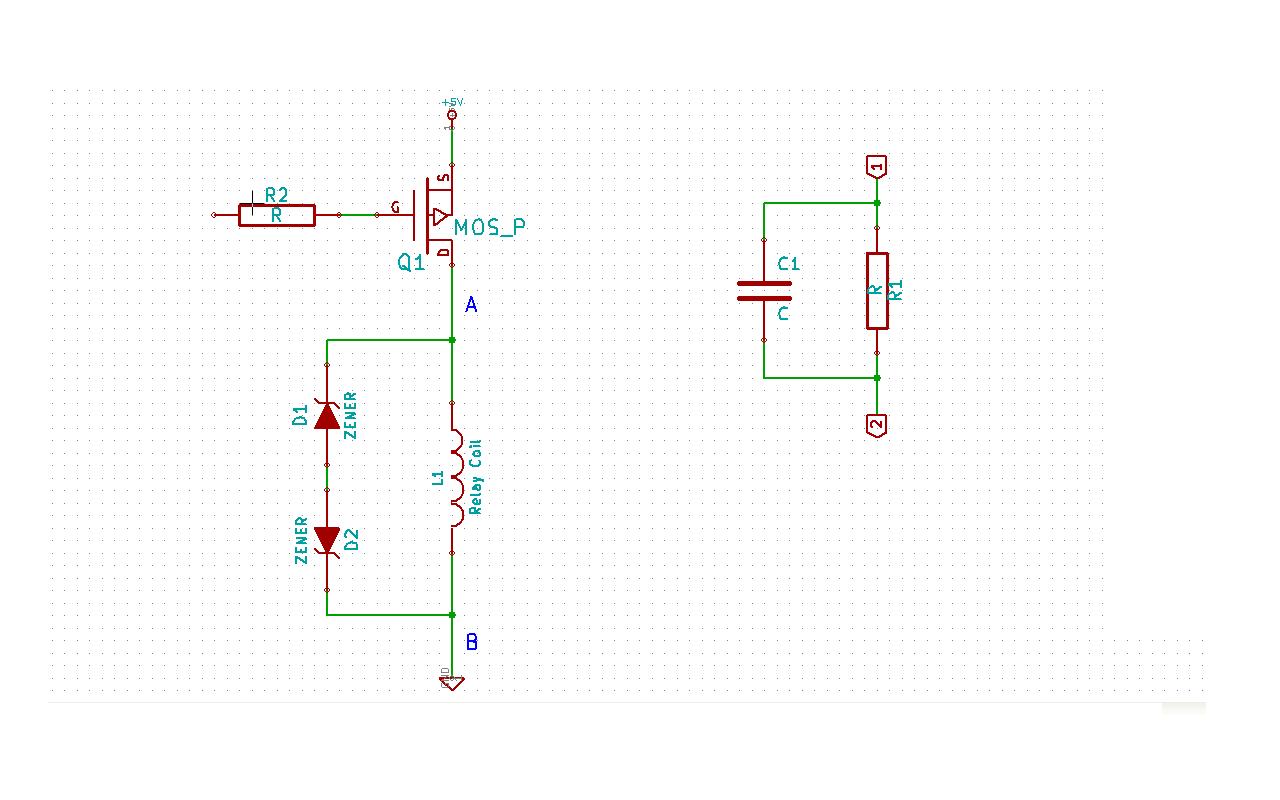

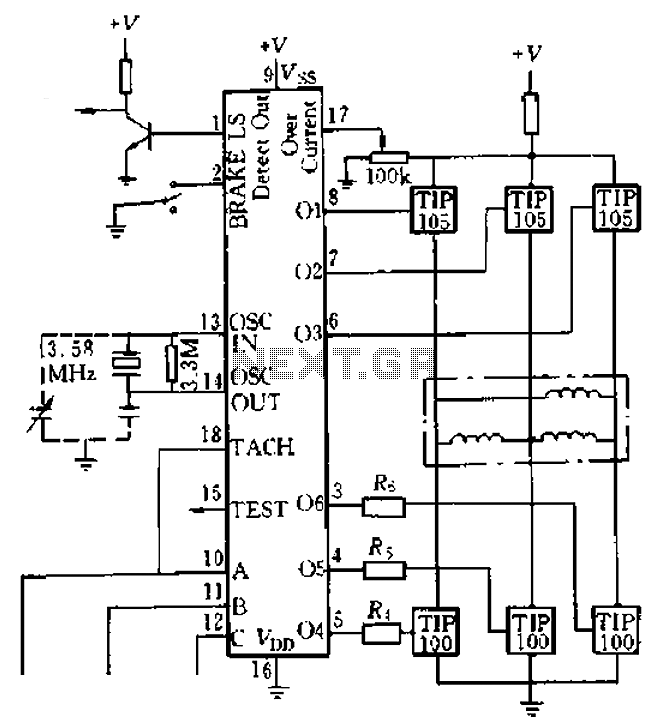

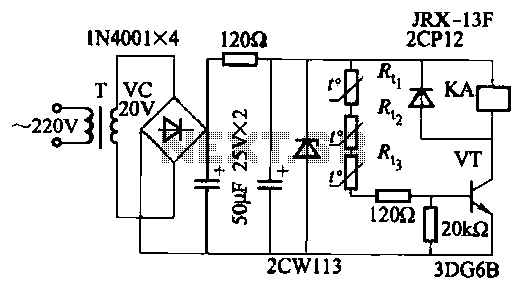

The semiconductor thermistor is an embedded thermal protection element that is sensitive to temperature, with a temperature error of 5. It is reliable, compact in size (diameter of 3.5 mm), and easy to install and embed in windings, making it suitable for use as a temperature sensing element. This thermistor effectively reflects the electrical winding temperatures in a three-phase stator winding, positioned close to the wire and secured with epoxy cement. The thermal resistance can be classified into negative temperature coefficient thermistors (NTC) and positive temperature coefficient thermistors (PTC). The circuit is illustrated in Figure 4-1, where Figures 4-1 (b) and (c) depict only one of the protection circuits, excluding the main circuit. These circuits consist of a switch circuit using a single tube amplifier. The thermistor type can be either RRC6 or MF-15, with characteristics of approximately 1 kΩ at 100 °C and around 0.6 kΩ at 110 °C.

The semiconductor thermistor serves as a critical component in thermal protection systems, particularly in electrical applications where monitoring and managing temperature is essential for operational safety and efficiency. The thermistor's sensitivity to temperature changes allows it to provide real-time feedback on the thermal state of the winding, which is crucial in preventing overheating and potential damage to the motor or other electrical components.

In a typical configuration, the thermistor is strategically placed near the three-phase stator windings to ensure accurate temperature readings. The use of epoxy cement not only secures the thermistor in place but also provides additional insulation and protection against environmental factors. The choice between NTC and PTC thermistors depends on the specific application requirements; NTC thermistors are generally used for applications requiring a decrease in resistance with increasing temperature, while PTC thermistors are used where an increase in resistance is desirable as temperatures rise.

The circuit design, as indicated in Figure 4-1, incorporates a switch circuit based on a single tube amplifier, which is essential for amplifying the signal from the thermistor. This amplification is necessary for effective temperature monitoring and control, ensuring that the system can react promptly to any changes in temperature. The selection of the appropriate thermistor type, such as RRC6 or MF-15, is critical, as it affects the accuracy and responsiveness of the temperature measurements. The specified resistance values at different temperatures provide insight into the thermistor's behavior and its suitability for the intended application.

Overall, the integration of a semiconductor thermistor in a thermal protection circuit enhances the reliability and safety of electrical systems, making it a vital component in modern electronic designs.Semiconductor thermistor embedded thermal protection element belongs, it is sensitive to temperature, temperature error of 5. Its reliability, small size (diameter 3. Smm), easy to install, easy to embed winding, use it as a temperature sensing element can effectively reflect the electrical winding temperatures motivation. Thermistor on the three-phase stator windings, close to the wire, with epoxy cement. Thermal resistance has a negative temperature coefficient thermistor (NTC) and positive temperature coefficient thermistor (PTC) of the points. Circuit shown in Figure 4-1. Wherein Figure 4-1 (b), (c) only one shown protection circuits, the main circuit not shown. They are a switch circuit consisting of a single tube amplifier. Thermistor brother., R. ., R., The choice RRC6 type or MF-15 type (lokfl, 20 ), this thermistor in about lkfl 100 when, 110 at about 0.6k, Cl.

The semiconductor thermistor serves as a critical component in thermal protection systems, particularly in electrical applications where monitoring and managing temperature is essential for operational safety and efficiency. The thermistor's sensitivity to temperature changes allows it to provide real-time feedback on the thermal state of the winding, which is crucial in preventing overheating and potential damage to the motor or other electrical components.

In a typical configuration, the thermistor is strategically placed near the three-phase stator windings to ensure accurate temperature readings. The use of epoxy cement not only secures the thermistor in place but also provides additional insulation and protection against environmental factors. The choice between NTC and PTC thermistors depends on the specific application requirements; NTC thermistors are generally used for applications requiring a decrease in resistance with increasing temperature, while PTC thermistors are used where an increase in resistance is desirable as temperatures rise.

The circuit design, as indicated in Figure 4-1, incorporates a switch circuit based on a single tube amplifier, which is essential for amplifying the signal from the thermistor. This amplification is necessary for effective temperature monitoring and control, ensuring that the system can react promptly to any changes in temperature. The selection of the appropriate thermistor type, such as RRC6 or MF-15, is critical, as it affects the accuracy and responsiveness of the temperature measurements. The specified resistance values at different temperatures provide insight into the thermistor's behavior and its suitability for the intended application.

Overall, the integration of a semiconductor thermistor in a thermal protection circuit enhances the reliability and safety of electrical systems, making it a vital component in modern electronic designs.Semiconductor thermistor embedded thermal protection element belongs, it is sensitive to temperature, temperature error of 5. Its reliability, small size (diameter 3. Smm), easy to install, easy to embed winding, use it as a temperature sensing element can effectively reflect the electrical winding temperatures motivation. Thermistor on the three-phase stator windings, close to the wire, with epoxy cement. Thermal resistance has a negative temperature coefficient thermistor (NTC) and positive temperature coefficient thermistor (PTC) of the points. Circuit shown in Figure 4-1. Wherein Figure 4-1 (b), (c) only one shown protection circuits, the main circuit not shown. They are a switch circuit consisting of a single tube amplifier. Thermistor brother., R. ., R., The choice RRC6 type or MF-15 type (lokfl, 20 ), this thermistor in about lkfl 100 when, 110 at about 0.6k, Cl.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713