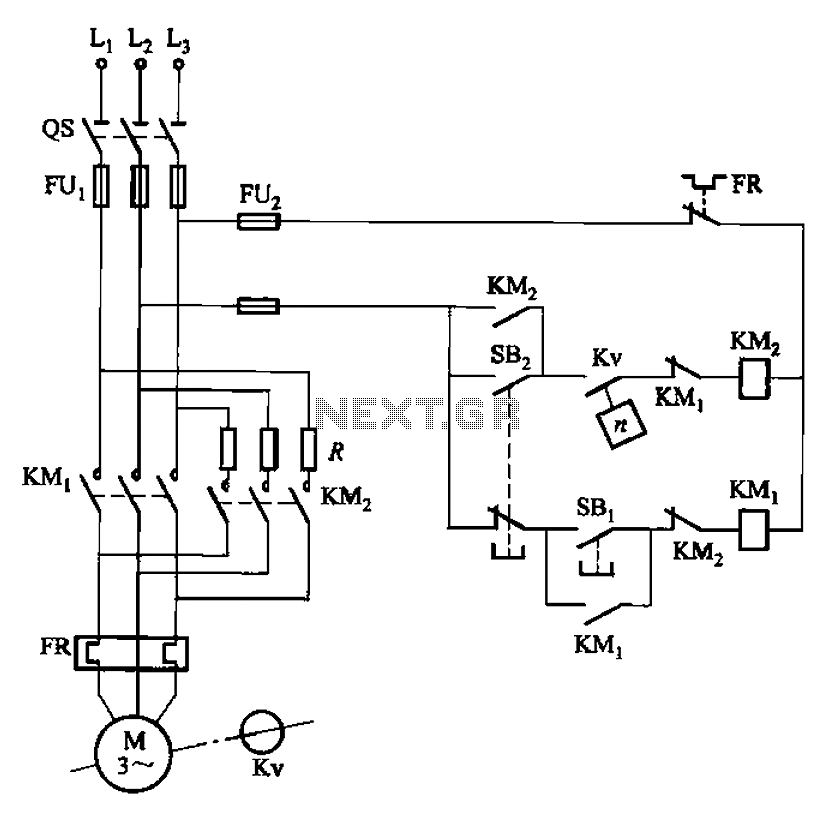

One-way operation of the brake circuit reverse

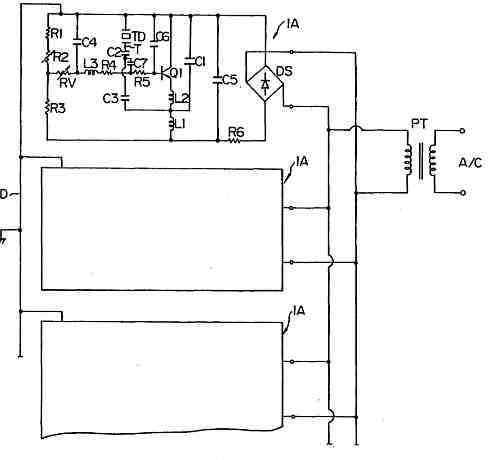

The circuit depicted in Figure 3-124 operates without an intermediate relay. Kv serves as the speed relay, activating when the electric motor speed exceeds 120 r/min while the contact is closed. If the speed drops below 100 r/min, the contacts open, leading to a shutdown. When this occurs, the KMi contact releases, and KMz pulls in to initiate plug braking. As the speed falls below 100 r/min, the Kv contacts open, resulting in KM2 releasing and concluding the braking process, which lasts approximately 1 to 3 seconds. The braking resistor R is included to limit the reverse current during braking and can also be connected to only two phases.

The circuit design incorporates a speed relay (Kv) that plays a crucial role in monitoring and controlling the operational speed of an electric motor. The functionality is contingent upon the motor speed, with specific thresholds set at 120 r/min and 100 r/min. When the motor operates above 120 r/min, the relay remains engaged, allowing the system to function normally. However, once the speed drops below 100 r/min, the Kv relay disengages, which triggers a series of actions to ensure safe operation.

Upon disengagement of the Kv relay, the KMi contact is released, which signifies that the motor should cease operation. Concurrently, KMz is activated to engage plug braking, a method that reverses the motor phase connections to rapidly decelerate the motor. This process is essential for applications requiring a quick stop to prevent damage or ensure safety.

The circuit includes a braking resistor (R) that serves to limit the reverse current generated during the braking phase. This is critical to protect the circuit components from potential damage due to excessive current. The resistor can be connected to only two of the three phases, providing flexibility in the circuit design while maintaining effective braking performance.

Once the motor speed has decreased to below 100 r/min, the Kv contacts open, which leads to the release of KM2. This action signifies the conclusion of the braking process, which is designed to last between 1 to 3 seconds, allowing for a controlled and safe stopping procedure. Overall, the circuit is designed to enhance the operational safety and efficiency of electric motor systems by integrating speed monitoring and responsive braking mechanisms. Circuit shown in Figure 3-124. The line does not use an intermediate relay. Figure, Kv is the speed relay, when the electric engine speed is greater than 120r/min when the cont act is closed, less than 100 r/min, the contacts open. Shutdown, contact KMi release put, KMz pull, plug braking. When the speed is lower than lOOr/min, Kv contacts open. KM2 release, the braking process ends (about 1 ~ 3s). Access braking resistor R purpose is to limit the reverse current brake. R can also be connected to only two phases.

The circuit design incorporates a speed relay (Kv) that plays a crucial role in monitoring and controlling the operational speed of an electric motor. The functionality is contingent upon the motor speed, with specific thresholds set at 120 r/min and 100 r/min. When the motor operates above 120 r/min, the relay remains engaged, allowing the system to function normally. However, once the speed drops below 100 r/min, the Kv relay disengages, which triggers a series of actions to ensure safe operation.

Upon disengagement of the Kv relay, the KMi contact is released, which signifies that the motor should cease operation. Concurrently, KMz is activated to engage plug braking, a method that reverses the motor phase connections to rapidly decelerate the motor. This process is essential for applications requiring a quick stop to prevent damage or ensure safety.

The circuit includes a braking resistor (R) that serves to limit the reverse current generated during the braking phase. This is critical to protect the circuit components from potential damage due to excessive current. The resistor can be connected to only two of the three phases, providing flexibility in the circuit design while maintaining effective braking performance.

Once the motor speed has decreased to below 100 r/min, the Kv contacts open, which leads to the release of KM2. This action signifies the conclusion of the braking process, which is designed to last between 1 to 3 seconds, allowing for a controlled and safe stopping procedure. Overall, the circuit is designed to enhance the operational safety and efficiency of electric motor systems by integrating speed monitoring and responsive braking mechanisms. Circuit shown in Figure 3-124. The line does not use an intermediate relay. Figure, Kv is the speed relay, when the electric engine speed is greater than 120r/min when the cont act is closed, less than 100 r/min, the contacts open. Shutdown, contact KMi release put, KMz pull, plug braking. When the speed is lower than lOOr/min, Kv contacts open. KM2 release, the braking process ends (about 1 ~ 3s). Access braking resistor R purpose is to limit the reverse current brake. R can also be connected to only two phases.