Oscillator Control & GPS

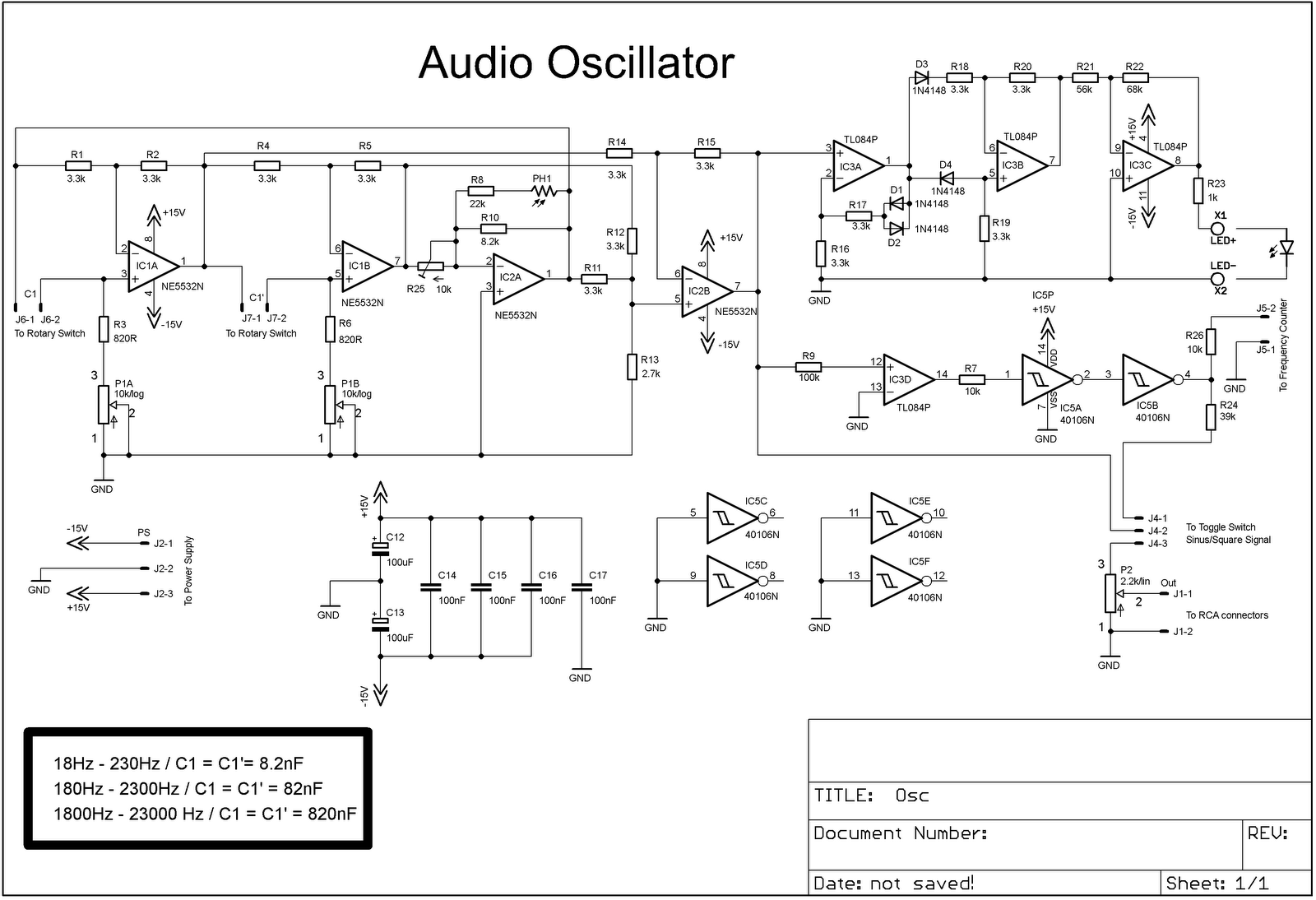

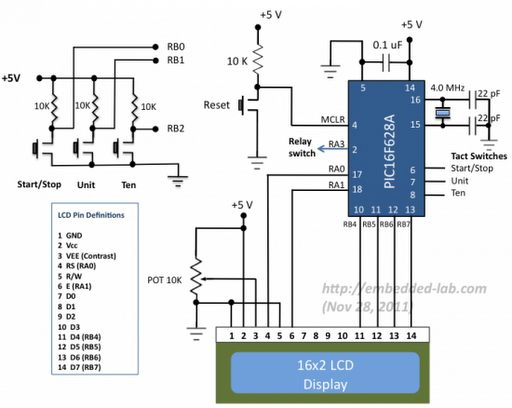

The VNGBOX microcontroller must generate a precise, high-resolution, and low-noise DC control voltage to accurately steer the reference oscillator phase. Any noise on this signal can introduce noise to the reference, and any non-linearity, particularly unexpected steps in the digital-to-analog conversion, can lead to stability issues. The circuit is capable of producing a very accurate and linear 12-bit DC voltage ranging from 0V to 5V (4096 steps of approximately 1mV). The microcontroller operates two parallel 6-bit PWM converters synchronously, with each converter utilizing six bits of the 12-bit control word. The most significant bits are output on signal EFC6, while the least significant bits are output on EFC0. Given that the most significant bits have 64 times the significance of the least significant bits, these signals must be combined with this gain ratio. Typically, a PWM digital-to-analog converter employs a low-pass filter, and this design follows suit, with both converters summing together and sharing a single filter capacitor. Input EFC6 is connected to a 5k resistance (two 10k resistors, R14 and R15, in parallel), while input EFC0 is connected to 320k (two 640k resistors, R16 and R17). The summation weighting at capacitor C7 yields a very linear control voltage with minimal ripple. The advantage of utilizing two 6-bit converters instead of a single 12-bit converter is that the PWM ripple frequency (clock frequency divided by two raised to the power of the number of bits) is significantly higher, making it easier to filter out in the low-pass filter. The PWM operates at 2kHz, resulting in a ripple frequency of 31.25Hz instead of 0.44Hz. Most oscillators (V-OCXO or V-TCXO) have a voltage control range of 0 - 5V or 0 - 12V, which can be directly controlled by connecting the VCO control input to R18/C7, forming an additional 0.1Hz low-pass filter. To eliminate power supply noise and PWM ripple, resistors R20 and R19 can be omitted. The long time-constant filters required for GPS locking are implemented in software, simplifying the hardware filter requirements. The positive portion of the range for the HP 10811A oscillator is notably linear and functions well within this range with a direct connection, provided that the mechanical adjustment can be slightly offset. If the control range of 0 - 5V is inadequate, or if the VCO input loads the circuit, a buffer amplifier may need to be added. It is advisable to use a quiet and stable oscillator supply for any amplifier added, as noise from the microcontroller supply will not be effectively rejected. If the control range is excessive (approximately ±5Hz maximum is needed), a resistor should be connected to ground at the junction of C7 and R14/R15/R16/R17. Some oscillators, including the HP 10811A, utilize a bipolar control voltage ranging from -5V to +5V. This configuration will not provide the full range without an amplifier, although the positive half of the range can be utilized by slightly offsetting the mechanical adjustment. However, it may be more convenient to use the arrangement shown, which includes a 10-turn potentiometer (R20 and R19). For negative output, the bottom of C7 should be connected to the -5V supply, which must be very noise-free. The configuration depicted allows the HP 10811A to have sufficient control range, albeit lacking gain. Optimal results with the VNGBOX are achieved using positive-only control as previously described. When the unit is set to mode 4 (command C00), the oscillator's internal mechanical adjustment should be calibrated to precisely 10MHz or as close as possible (the REFMON4 sub-graph phase plot should show minimal slope). The unit should be set to mode 4 (command C00), and the 10-turn potentiometer should be adjusted to mid-range (-2.5V), positioning the junction of R18/C7 close to 0V. The internal mechanical adjustment of the oscillator should be fine-tuned for a frequency close to 10MHz, followed by trimming the remaining slope with R20. The schematic illustrates the HP 10811A oscillator, although other oscillators may have different connections and varying power supply requirements for both the oscillator and the oven.

This circuit design effectively addresses the need for precision and stability in generating control voltages for reference oscillators. The use of two parallel 6-bit PWM converters enhances the performance of the system by allowing for higher ripple frequencies, which are easier to filter out. The careful selection of resistors and capacitors ensures that the output voltage is both linear and stable, minimizing the impact of noise. The provision for buffer amplifiers and adjustments for different oscillator types further enhances the versatility and applicability of the VNGBOX microcontroller in various electronic applications.The VNGBOX micro needs to produce a very accurate, high resolution and very noise-free DC control voltage to steer the reference oscillator phase accurately. Any noise on this signal will result in noise on the reference; any non-linearity, especially any unexpected steps in the digital to analog conversion, will result in stability problems.

The circuit is able to generate a very accurate and linear 12-bit DC voltage from 0V to 5V (4096 steps of about 1mV). The micro operates two parallel 6-bit PWM converters, which operate synchronously. Each converter uses six bits of the 12-bit control word. The most significant bits are output on signal EFC6, and the least significant on EFC0. Since the most significant bits have 64 times the significance of the least significant bits, the two signals need to be combined with this gain ratio.

A PWM D-A converter usually operates with a low-pass filter, and this design is no different, except the two converters sum together and share a single filter capacitor. Input EFC6 has a 5k resistance (two 10k resistors R14 and R15 in parallel), while input EFC0 has 320k (two 640k resistors, R16 and R17).

The weighting of the sum at C7 gives a very linear control voltage with very little ripple. The advantage of using two six-bit converters instead of one 12-bit converter, is that the PWM ripple frequency (clock frequency divided by two to the power of the number of bits) is much higher, making the ripple much easier to remove in the low pass filter. The PWM operates at 2kHz, so the ripple frequency is 31. 25Hz instead of 0. 44Hz. Most oscillators (V-OCXO or V-TCXO) have a voltage control range of 0 - 5V or 0 - 12V. These can be controlled directly by connecting the VCO control input directly to R18/C7, which forms a further 0.

1Hz low pass filter. Just omit R20 and R19. The low pass filter is intended to remove power supply noise and PWM ripple. The very long time-constant filters necessary for GPS locking operate in software, which considerably simplifies the filter requirements. It turns out that the positive part of the range of the HP 10811A is quite linear, and works well over this range with direct connection, provided the mechanical adjustment can be offset slightly.

If the control range of 0 - 5V is not sufficient, or if the VCO input loads the circuit, you may need to add a buffer amplifier here. Use the quiet and stable oscillator supply for any amplifier you add here, as the noise from the micro supply will not be well rejected.

If the control range is excessive (you need only about ±5Hz at most), connect a resistor to ground on the junction of C7 and R14/R15/R16/R17. Some oscillators (including the HP 10811A) use a bipolar control voltage, with a range of -5V to +5V.

This unit will not provide the full range without an amplifier. You can use just the positive half of the range by offsetting the mechanical adjustment slightly, but it may be more convenient to use the arrangement shown, with 10-turn pot R20 and R19. If you plan to take the output negative, move the bottom of C7 to the -5V supply, which must be very noise-free.

With the arrangement shown, the HP 10811A has more than enough control range, but lacks gain. Best results are achieved with the VNGBOX using positive-only control, as mentioned above. With the unit set in mode 4 (command C00), adjust the oscillator internal mechanical adjustment for exactly 10MHz, or as close as you can get (REFMON4 sub-graph phase plot has minimum slope). Set the unit set in mode 4 (command C00), adjust the 10-turn pot to mid-range (-2. 5V), which should put the junction of R18/C7 at close to 0V. Adjust the oscillator internal mechanical adjustment for close to 10MHz, then trim out the rest of the slope with R20.

The schematic shows the HP 10811A oscillator. Other oscillators will have different connections, and different oscillator and oven power supply requirements. If you have a goo 🔗 External reference

This circuit design effectively addresses the need for precision and stability in generating control voltages for reference oscillators. The use of two parallel 6-bit PWM converters enhances the performance of the system by allowing for higher ripple frequencies, which are easier to filter out. The careful selection of resistors and capacitors ensures that the output voltage is both linear and stable, minimizing the impact of noise. The provision for buffer amplifiers and adjustments for different oscillator types further enhances the versatility and applicability of the VNGBOX microcontroller in various electronic applications.The VNGBOX micro needs to produce a very accurate, high resolution and very noise-free DC control voltage to steer the reference oscillator phase accurately. Any noise on this signal will result in noise on the reference; any non-linearity, especially any unexpected steps in the digital to analog conversion, will result in stability problems.

The circuit is able to generate a very accurate and linear 12-bit DC voltage from 0V to 5V (4096 steps of about 1mV). The micro operates two parallel 6-bit PWM converters, which operate synchronously. Each converter uses six bits of the 12-bit control word. The most significant bits are output on signal EFC6, and the least significant on EFC0. Since the most significant bits have 64 times the significance of the least significant bits, the two signals need to be combined with this gain ratio.

A PWM D-A converter usually operates with a low-pass filter, and this design is no different, except the two converters sum together and share a single filter capacitor. Input EFC6 has a 5k resistance (two 10k resistors R14 and R15 in parallel), while input EFC0 has 320k (two 640k resistors, R16 and R17).

The weighting of the sum at C7 gives a very linear control voltage with very little ripple. The advantage of using two six-bit converters instead of one 12-bit converter, is that the PWM ripple frequency (clock frequency divided by two to the power of the number of bits) is much higher, making the ripple much easier to remove in the low pass filter. The PWM operates at 2kHz, so the ripple frequency is 31. 25Hz instead of 0. 44Hz. Most oscillators (V-OCXO or V-TCXO) have a voltage control range of 0 - 5V or 0 - 12V. These can be controlled directly by connecting the VCO control input directly to R18/C7, which forms a further 0.

1Hz low pass filter. Just omit R20 and R19. The low pass filter is intended to remove power supply noise and PWM ripple. The very long time-constant filters necessary for GPS locking operate in software, which considerably simplifies the filter requirements. It turns out that the positive part of the range of the HP 10811A is quite linear, and works well over this range with direct connection, provided the mechanical adjustment can be offset slightly.

If the control range of 0 - 5V is not sufficient, or if the VCO input loads the circuit, you may need to add a buffer amplifier here. Use the quiet and stable oscillator supply for any amplifier you add here, as the noise from the micro supply will not be well rejected.

If the control range is excessive (you need only about ±5Hz at most), connect a resistor to ground on the junction of C7 and R14/R15/R16/R17. Some oscillators (including the HP 10811A) use a bipolar control voltage, with a range of -5V to +5V.

This unit will not provide the full range without an amplifier. You can use just the positive half of the range by offsetting the mechanical adjustment slightly, but it may be more convenient to use the arrangement shown, with 10-turn pot R20 and R19. If you plan to take the output negative, move the bottom of C7 to the -5V supply, which must be very noise-free.

With the arrangement shown, the HP 10811A has more than enough control range, but lacks gain. Best results are achieved with the VNGBOX using positive-only control, as mentioned above. With the unit set in mode 4 (command C00), adjust the oscillator internal mechanical adjustment for exactly 10MHz, or as close as you can get (REFMON4 sub-graph phase plot has minimum slope). Set the unit set in mode 4 (command C00), adjust the 10-turn pot to mid-range (-2. 5V), which should put the junction of R18/C7 at close to 0V. Adjust the oscillator internal mechanical adjustment for close to 10MHz, then trim out the rest of the slope with R20.

The schematic shows the HP 10811A oscillator. Other oscillators will have different connections, and different oscillator and oven power supply requirements. If you have a goo 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713