radio controlled electronic flash

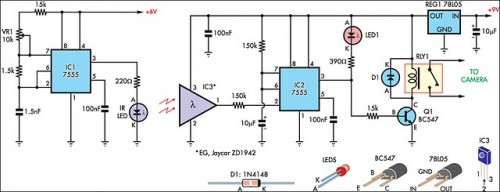

A radio-controlled electronic flash is an essential tool for any photographer's kit, frequently utilized by professionals. For instance, a wedding photographer may position one behind the bride to illuminate her gown and veil without visible wires in the shot. To construct this control, an old R/C car, preferably of the simplest type, is required; these can often be found inexpensively at school fairs and garage sales. A standard car typically operates on 3V (using two cells) while the transmitter functions on 9V. Prior to starting the project, it is crucial to verify that the car's electronics are functional. The condition of the wheels or motor is irrelevant, as access to the motor leads is necessary. Usually, one lead is positive relative to the other when the remote is not activated. These leads should be labeled accordingly. Upon pressing the remote button, the polarity of the motor leads will switch. Additionally, a flash extension cord, which can be cut into two parts, is needed. At the transmitter end, the camera side of the extension cord is inserted into the case and soldered to the control button contacts. These contacts are in series with the battery supply; therefore, if opening the transmitter is not preferred, one of the battery leads can be cut, and the flash extension cord can be connected in the created gap. The remote button needs to be taped down to maintain a permanent closed state. At the receiver end, the normally negative motor lead connects to the gate circuit of an SCR, while the normally positive lead connects to the SCR's cathode. When the transmitter is activated by the camera's contacts, the lead polarity reverses, and the SCR functions as a switch to trigger a portable electronic flash through the other half of the flash extension cord. The transmitter can be attached to the camera using a flash bracket or by screwing it into the tripod socket, based on the most convenient setup. Additional components in the receiver can be mounted on Veroboard and placed in the space previously occupied by the electric motor. For aesthetic purposes, the receiver and extra components may also be housed in a standard jiffy box.

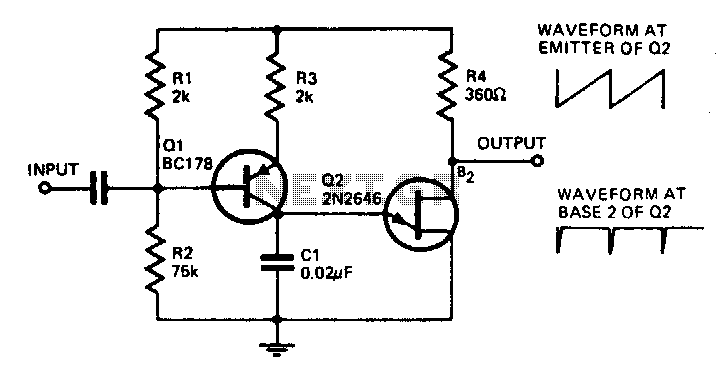

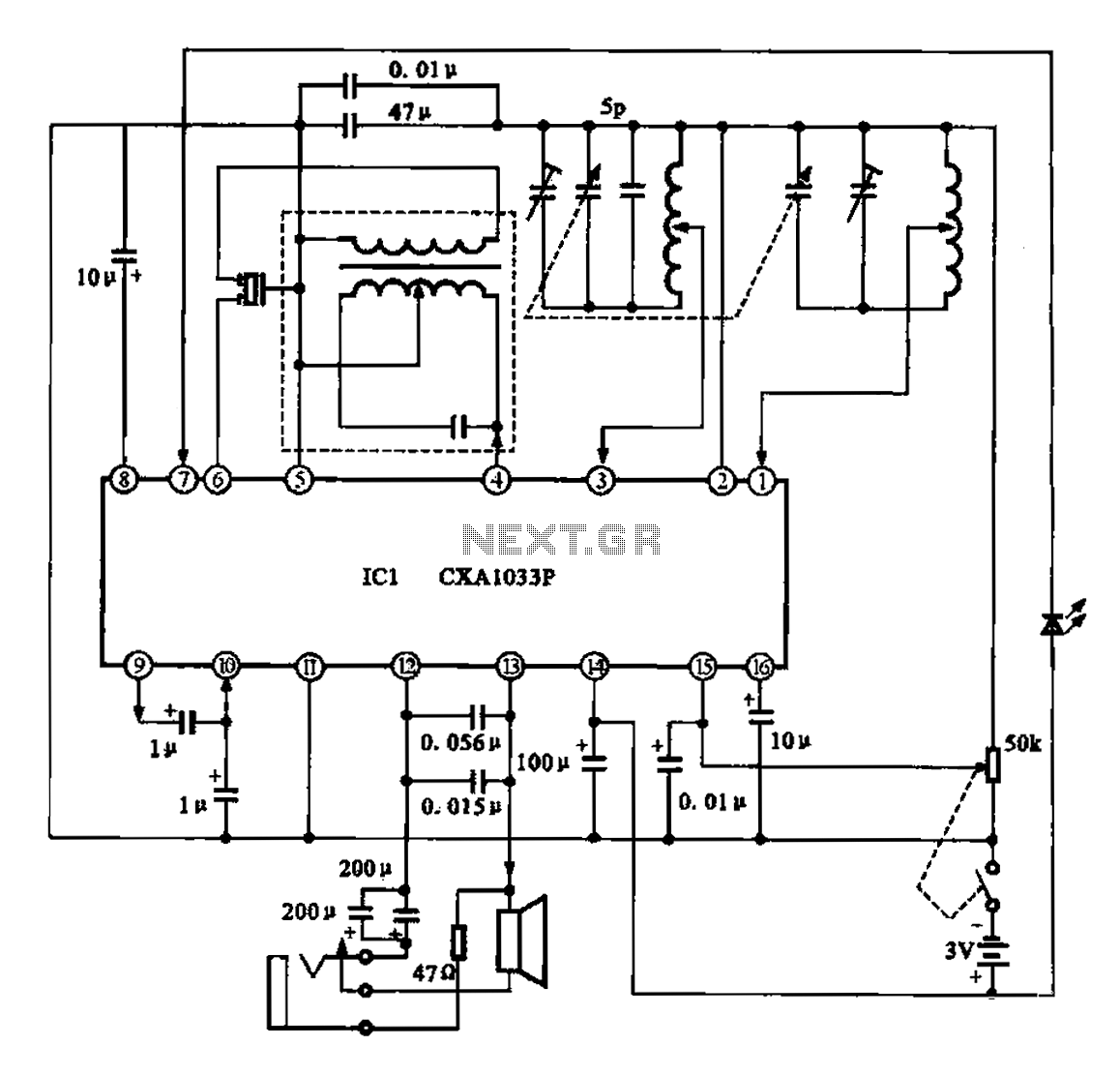

The radio-controlled electronic flash circuit integrates several key components to ensure reliable operation. The R/C car serves as the primary control mechanism, utilizing its built-in electronics to facilitate remote operation. The motor leads, which are modified to connect with an SCR, allow for control over the flash operation. The SCR (Silicon Controlled Rectifier) is crucial as it acts as a switch that can handle the high current required to trigger the flash unit.

To elaborate on the connection process, when the remote button is activated, it sends a signal to the transmitter, which in turn alters the polarity of the motor leads. This change is detected by the SCR, which is configured to switch on when the gate receives a positive signal. The flash extension cord, which connects the SCR to the electronic flash, must be carefully managed to ensure that it can handle the necessary voltage and current without degradation.

The arrangement of the components can vary based on the available space and aesthetic preferences. Utilizing a jiffy box not only protects the electronic components but also provides a professional appearance, making it suitable for use in various photography settings. The integration of Veroboard for additional circuit components enables a compact and efficient layout, ensuring that the system remains lightweight and portable.

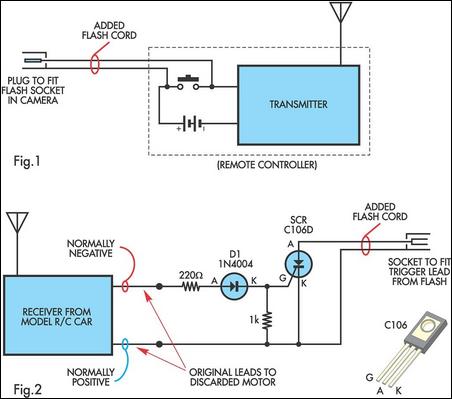

Overall, this circuit design exemplifies a practical application of radio control technology in photography, enhancing the capabilities of photographers by allowing them to control flash lighting without the constraints of wires. The reliability and simplicity of the system make it an attractive option for both amateur and professional photographers seeking to improve their lighting techniques.A radio controlled electronic flash is a useful item in any photographers kit. Professionals use them all the time. For example, a wedding photographer would put one behind the bride to back-light her gown and veil. You dont want wires showing in a shot like that. To build this control you will need an old R/C car (the simplest sort) in which the car runs in reverse at switch-on and goes ahead only when the remote is operated. They can be picked up cheaply as school fetes and garage sales. A typical car will run from 3V (two cells) and use 9V in the transmitter. Before proceeding, make sure that the electronics in the car are operating. It doesnt matter if the wheels are broken or the motor is dead. You need to gain access to the leads to the motor. Normally (ie, without the remote operating), one is positive with respect to the other. Label them accordingly. On pressing the remote button, the polarity of the motor leads should swap. You will also need a flash extension cord you can cut into two sections. At the transmitter, the camera end of the extension cord is fed into the case and soldered to the control button contacts, as shown in Fig. 1. The contacts are in series with the battery supply, so if you dont want to open the transmitter, just cut one of the battery leads and connect the flash extension cord into the gap so created.

You will then need to tape down the remote button so that it is permanently operated (ie, closed). All that needs to be done at the receiver end is to connect the normally negative motor lead to the gate circuit of an SCR, as shown in Fig. 2, while the normally positive lead goes to the cathode of the SCR. Now, when the transmitter is operated by the cameras contacts, the lead polarity is reversed and the SCR acts as a switch to fire a portable electronic flash via the other half of the flash extension cord.

The transmitter can be attached to the camera via a flash bracket or a screw into the tripod socket, depending on what is the most convenient arrangement. The added components in the receiver can be mounted on Veroboard and housed in the space where the electric motor was.

If appearance is a primary consideration, the receiver and the added components could be mounted in a standard jiffy box. 🔗 External reference

The radio-controlled electronic flash circuit integrates several key components to ensure reliable operation. The R/C car serves as the primary control mechanism, utilizing its built-in electronics to facilitate remote operation. The motor leads, which are modified to connect with an SCR, allow for control over the flash operation. The SCR (Silicon Controlled Rectifier) is crucial as it acts as a switch that can handle the high current required to trigger the flash unit.

To elaborate on the connection process, when the remote button is activated, it sends a signal to the transmitter, which in turn alters the polarity of the motor leads. This change is detected by the SCR, which is configured to switch on when the gate receives a positive signal. The flash extension cord, which connects the SCR to the electronic flash, must be carefully managed to ensure that it can handle the necessary voltage and current without degradation.

The arrangement of the components can vary based on the available space and aesthetic preferences. Utilizing a jiffy box not only protects the electronic components but also provides a professional appearance, making it suitable for use in various photography settings. The integration of Veroboard for additional circuit components enables a compact and efficient layout, ensuring that the system remains lightweight and portable.

Overall, this circuit design exemplifies a practical application of radio control technology in photography, enhancing the capabilities of photographers by allowing them to control flash lighting without the constraints of wires. The reliability and simplicity of the system make it an attractive option for both amateur and professional photographers seeking to improve their lighting techniques.A radio controlled electronic flash is a useful item in any photographers kit. Professionals use them all the time. For example, a wedding photographer would put one behind the bride to back-light her gown and veil. You dont want wires showing in a shot like that. To build this control you will need an old R/C car (the simplest sort) in which the car runs in reverse at switch-on and goes ahead only when the remote is operated. They can be picked up cheaply as school fetes and garage sales. A typical car will run from 3V (two cells) and use 9V in the transmitter. Before proceeding, make sure that the electronics in the car are operating. It doesnt matter if the wheels are broken or the motor is dead. You need to gain access to the leads to the motor. Normally (ie, without the remote operating), one is positive with respect to the other. Label them accordingly. On pressing the remote button, the polarity of the motor leads should swap. You will also need a flash extension cord you can cut into two sections. At the transmitter, the camera end of the extension cord is fed into the case and soldered to the control button contacts, as shown in Fig. 1. The contacts are in series with the battery supply, so if you dont want to open the transmitter, just cut one of the battery leads and connect the flash extension cord into the gap so created.

You will then need to tape down the remote button so that it is permanently operated (ie, closed). All that needs to be done at the receiver end is to connect the normally negative motor lead to the gate circuit of an SCR, as shown in Fig. 2, while the normally positive lead goes to the cathode of the SCR. Now, when the transmitter is operated by the cameras contacts, the lead polarity is reversed and the SCR acts as a switch to fire a portable electronic flash via the other half of the flash extension cord.

The transmitter can be attached to the camera via a flash bracket or a screw into the tripod socket, depending on what is the most convenient arrangement. The added components in the receiver can be mounted on Veroboard and housed in the space where the electric motor was.

If appearance is a primary consideration, the receiver and the added components could be mounted in a standard jiffy box. 🔗 External reference