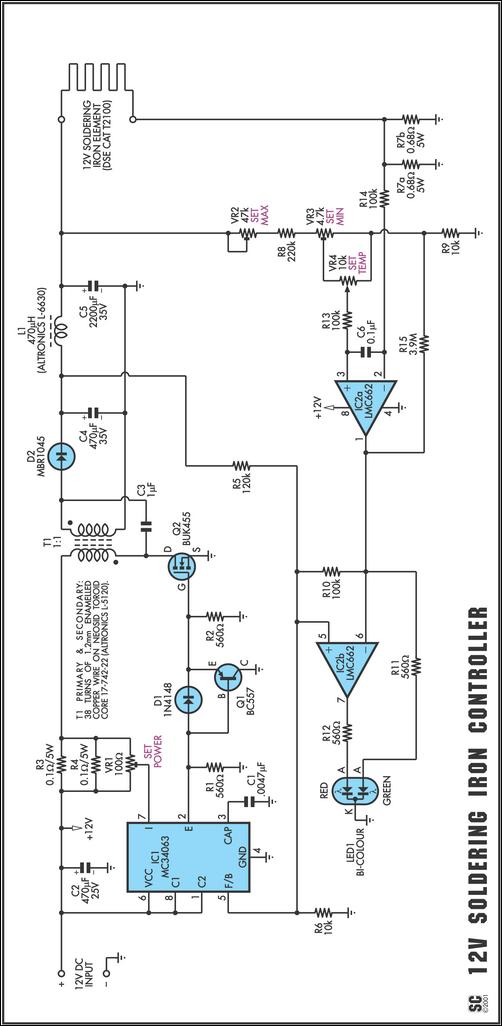

temperature controlled soldering iron

One reason commercial soldering stations are costly is that they typically use soldering irons equipped with built-in temperature sensors, like thermocouples. This circuit design eliminates the necessity for a specialized sensor by directly sensing the temperature of a soldering iron's heating element through its resistance. Consequently, this circuit can function with any soldering iron that has a resistance that varies predictably and in the appropriate direction with temperature (i.e., a positive temperature coefficient).

The described circuit operates by measuring the resistance of the soldering iron's heating element, which changes with temperature due to its positive temperature coefficient (PTC). The fundamental principle is that as the temperature of the heating element increases, its resistance also increases. This relationship allows the circuit to infer the temperature without relying on a separate temperature sensor.

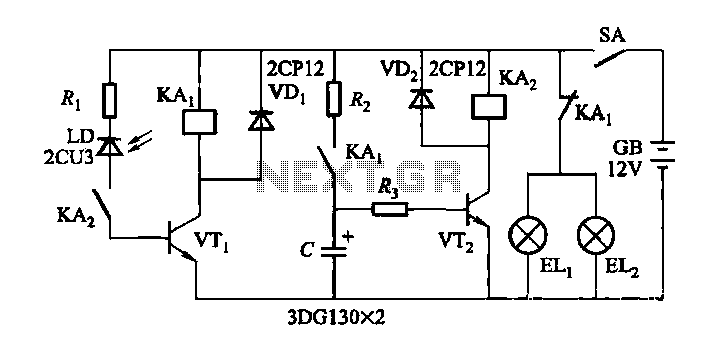

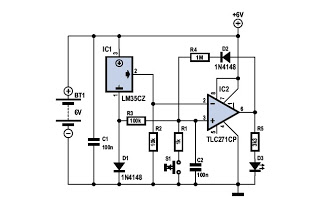

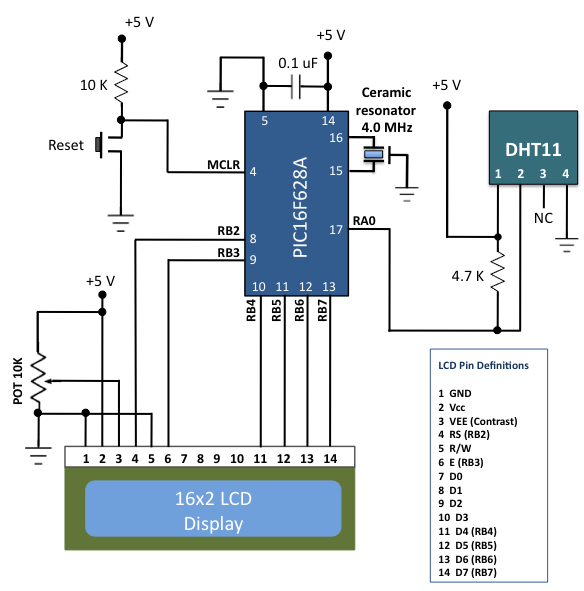

The circuit typically includes a microcontroller or a dedicated analog circuit that can measure the resistance of the heating element. A voltage divider configuration can be employed, where the soldering iron's resistance is part of the divider. The output voltage from the divider will vary with changes in the resistance of the heating element, which can be read by the microcontroller's analog-to-digital converter (ADC).

To ensure accurate temperature readings, the circuit may incorporate calibration routines to establish a baseline resistance at a known temperature. This calibration process allows the system to create a lookup table or apply a mathematical formula to convert resistance readings into temperature values. Additionally, the circuit can include feedback mechanisms to adjust the power supplied to the heating element, maintaining the desired temperature by controlling the on/off state of the power supply.

Protection features, such as over-temperature cutoffs and thermal fuses, can also be integrated to prevent overheating and potential damage to the soldering iron or the circuit itself. Overall, this innovative approach not only reduces costs by eliminating the need for specialized sensors but also enhances the versatility of soldering stations, making them compatible with a wider range of soldering irons.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors, such as thermocouples. This circuit eliminates the need for a special sensor because it senses the temperature of a soldering iron heating element directly from its resistance.

Thus this circuit will, in principle, work with any iron with a resistance which varies predictably and in the right direction with temperature (ie, positive temperature coefficient).. 🔗 External reference

The described circuit operates by measuring the resistance of the soldering iron's heating element, which changes with temperature due to its positive temperature coefficient (PTC). The fundamental principle is that as the temperature of the heating element increases, its resistance also increases. This relationship allows the circuit to infer the temperature without relying on a separate temperature sensor.

The circuit typically includes a microcontroller or a dedicated analog circuit that can measure the resistance of the heating element. A voltage divider configuration can be employed, where the soldering iron's resistance is part of the divider. The output voltage from the divider will vary with changes in the resistance of the heating element, which can be read by the microcontroller's analog-to-digital converter (ADC).

To ensure accurate temperature readings, the circuit may incorporate calibration routines to establish a baseline resistance at a known temperature. This calibration process allows the system to create a lookup table or apply a mathematical formula to convert resistance readings into temperature values. Additionally, the circuit can include feedback mechanisms to adjust the power supplied to the heating element, maintaining the desired temperature by controlling the on/off state of the power supply.

Protection features, such as over-temperature cutoffs and thermal fuses, can also be integrated to prevent overheating and potential damage to the soldering iron or the circuit itself. Overall, this innovative approach not only reduces costs by eliminating the need for specialized sensors but also enhances the versatility of soldering stations, making them compatible with a wider range of soldering irons.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors, such as thermocouples. This circuit eliminates the need for a special sensor because it senses the temperature of a soldering iron heating element directly from its resistance.

Thus this circuit will, in principle, work with any iron with a resistance which varies predictably and in the right direction with temperature (ie, positive temperature coefficient).. 🔗 External reference