remote shift light

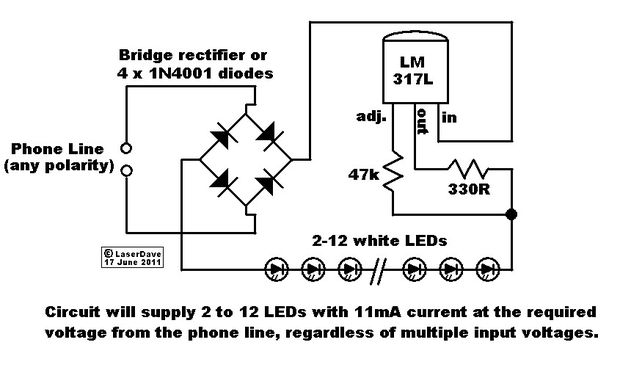

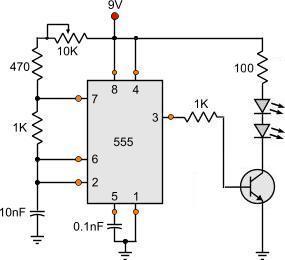

Replacing the resistor/transistor with an n-channel power MOSFET and substituting the relay/protection diode with a light bulb results in a simplified circuit that mirrors the original design, provided one end of the light bulb is connected to +12V. If the MOSFET is selected appropriately, it may not require a heatsink, allowing the entire circuit to be assembled on a connecting block and wrapped in insulating tape. The previously mentioned circuit activates when a voltage is applied. However, the existing LED circuit intended for interfacing has not been described in detail. Further information about the LED circuit is necessary to determine how it is driven. The LED may be configured as low-side switched, but this can only be confirmed through measurement or by consulting the bike schematic. The more details available regarding the existing circuit, the easier the modification will be. In the absence of this information, the design modification becomes more complex as it must accommodate various possibilities. Some designers prefer a conservative approach that considers all scenarios, while others adopt a minimalist strategy to avoid duplicating functionality. The suggestion to utilize a transistor to drive the bulb directly is supported; additionally, it is advisable to place a capacitor and a resistor (both in parallel) from the transistor base to ground. This configuration reduces the likelihood of the bulb turning on due to voltage spikes and provides a smoother turn-on/off operation, thereby extending bulb life. A 3.3k ohm resistor and a 1uF capacitor are recommended. It is standard practice to include a resistor (typically around 100k ohms) between the gate and source of the MOSFET to prevent it from picking up signals when the input is floating, thereby avoiding partial activation that could lead to overheating and damage to the insulating tape. This resistor can be inserted into the same connection block as the MOSFET pins. Another common practice is to add a resistor in series with the gate pin to prevent oscillations at radio frequencies; however, this gate series resistor may be omitted to adhere to the KISS (Keep It Simple, Stupid) principle, allowing for direct connection of the MOSFET's pins to the connecting block without the need for a complex PCB design. The term "high side" refers to circuits like traditional horn or hooter systems, where one side of the device is connected to +12V, while the other side connects to a button that completes the circuit to ground, which is considered "low side." To further investigate the LED circuit, it is essential to determine what drives the LED. If it is a switch mounted on the engine block, the number of wires connected to the switch must be identified, as well as whether any of these wires connect to ground or +12V. Alternatively, if the LED is driven by an ECU, measuring the voltage across the LED with respect to ground is necessary, which can be accomplished by connecting the negative probe to ground and probing each side of the LED with the positive probe.

The proposed circuit modification involves utilizing an n-channel power MOSFET to replace traditional components, which streamlines the design while maintaining functionality. The MOSFET operates as a switch, controlling the power to the light bulb without the need for a relay, thus reducing size and complexity. The careful selection of the MOSFET is critical; it should be rated for the appropriate voltage and current levels to ensure safe operation without overheating. The inclusion of a resistor and capacitor in parallel at the transistor base is a prudent measure to mitigate transient voltages that could inadvertently trigger the bulb, thereby enhancing the longevity of the light source. The resistor between the gate and source of the MOSFET is essential for stability, preventing unintended activation due to floating inputs. The overall design should prioritize simplicity while ensuring that all necessary protective measures are in place to safeguard against potential electrical issues. This circuit can be effectively implemented in various applications, including automotive lighting systems, where reliability and efficiency are paramount. Proper documentation of the circuit design and thorough testing should be conducted to validate the functionality and safety of the modified circuit before deployment.If you replace the resistor/transistor with an n-ch power mosfet, and replace the relay/prot diode with a light bulb, you`ll have a simpler circuit that replicates the circuit you posted (assuming it drives a light bulb with one end connected to +12). If the Fet is chosen carefully, it won`t need a heatsink, and the whole circuit can be made on aconnecting block and have insulating tape

wrapped around it. THough having just said, the circuit you posted switches on when there is a voltage applied. You didn`t describe the existing LED circuit you wish to interface to. Can you tell us more about the LED circuit How is the LED driven The LED could be wired that way (low-side switched). You won`t know until you measure it, or look at the bike schematic. The more that can be found out about the existing circuit, the simpler the modification will be. If there isn`t this kind of information then the modification design becomes a little more complicated because it has to cater for all possibilities.

Some designers prefer to always cater for any possibilty (conservative) while other designers find out all they can, so as not to duplicate functionality (minimalist). I agree with marc to use the transistor to drive th ebulb direct, but allso you might want to put a capacitor and a resistor (both in parallel) from the transistor base to ground, this will reduce chance of it turning on with spikes and will provide a more gentle turn on/off of the bulb to increase bulb life.

Something like 3. 3k and 1uF should work. Roman Black - PICs and electronics. Author of BTc PIC-sound encoder, Shift1-LCD project, the TalkBotBrain talking PIC controller, LiniStepper open-source microstepping motor driver, the Black Regulator 2-transistor SMPS, and probably some other stuff; It`s the "done thing" to include a resistor (of a high-ish value, say 100K), between the gate and source, to prevent the Fet picking up signal when the input is unconnected floating. This would prevent the fet "half-turning on" (if the input was ever disconnected, the fet warming up and then melting the insulating tape wrapped around it and possibly burning a hole somewhere.

The resistor push into the same conn-block holes as the fet pins. Another `done thing` (more like a ritual) is the adding of a resistor in series with gate pin, the idea being that it "prevents oscillations at RF frequencies". I would say omit this gate series resistor completely (using the `KISS principle`), because you want to connect the FET`s 3 pins directly into a connecting block, not have to build a full `bells and whistles` circuit on a PCB!

When someone says something is "in the high side" this means for example as applied to the good old fashioned Horn or Hooter circuit, where one side of the hooter is connected to +12. The hooter is in the high side. The other side of the hooter is wired to the button, which completes the circuit to Ground. The button would be described as in the "Low Side". Take a different tack. what drives the LED Is it a Switch screwed into the Engine Block If so how many wires does Switch have Is one of these wires connect to ground Or maybe one connects to + 12V Or does the LED get driven from an ECU If so, could you measure the voltage of the LED, with respect to ground Do this by clipping your negative probe to ground and probe either side of the LED with the red probe.

🔗 External reference

The proposed circuit modification involves utilizing an n-channel power MOSFET to replace traditional components, which streamlines the design while maintaining functionality. The MOSFET operates as a switch, controlling the power to the light bulb without the need for a relay, thus reducing size and complexity. The careful selection of the MOSFET is critical; it should be rated for the appropriate voltage and current levels to ensure safe operation without overheating. The inclusion of a resistor and capacitor in parallel at the transistor base is a prudent measure to mitigate transient voltages that could inadvertently trigger the bulb, thereby enhancing the longevity of the light source. The resistor between the gate and source of the MOSFET is essential for stability, preventing unintended activation due to floating inputs. The overall design should prioritize simplicity while ensuring that all necessary protective measures are in place to safeguard against potential electrical issues. This circuit can be effectively implemented in various applications, including automotive lighting systems, where reliability and efficiency are paramount. Proper documentation of the circuit design and thorough testing should be conducted to validate the functionality and safety of the modified circuit before deployment.If you replace the resistor/transistor with an n-ch power mosfet, and replace the relay/prot diode with a light bulb, you`ll have a simpler circuit that replicates the circuit you posted (assuming it drives a light bulb with one end connected to +12). If the Fet is chosen carefully, it won`t need a heatsink, and the whole circuit can be made on aconnecting block and have insulating tape

wrapped around it. THough having just said, the circuit you posted switches on when there is a voltage applied. You didn`t describe the existing LED circuit you wish to interface to. Can you tell us more about the LED circuit How is the LED driven The LED could be wired that way (low-side switched). You won`t know until you measure it, or look at the bike schematic. The more that can be found out about the existing circuit, the simpler the modification will be. If there isn`t this kind of information then the modification design becomes a little more complicated because it has to cater for all possibilities.

Some designers prefer to always cater for any possibilty (conservative) while other designers find out all they can, so as not to duplicate functionality (minimalist). I agree with marc to use the transistor to drive th ebulb direct, but allso you might want to put a capacitor and a resistor (both in parallel) from the transistor base to ground, this will reduce chance of it turning on with spikes and will provide a more gentle turn on/off of the bulb to increase bulb life.

Something like 3. 3k and 1uF should work. Roman Black - PICs and electronics. Author of BTc PIC-sound encoder, Shift1-LCD project, the TalkBotBrain talking PIC controller, LiniStepper open-source microstepping motor driver, the Black Regulator 2-transistor SMPS, and probably some other stuff; It`s the "done thing" to include a resistor (of a high-ish value, say 100K), between the gate and source, to prevent the Fet picking up signal when the input is unconnected floating. This would prevent the fet "half-turning on" (if the input was ever disconnected, the fet warming up and then melting the insulating tape wrapped around it and possibly burning a hole somewhere.

The resistor push into the same conn-block holes as the fet pins. Another `done thing` (more like a ritual) is the adding of a resistor in series with gate pin, the idea being that it "prevents oscillations at RF frequencies". I would say omit this gate series resistor completely (using the `KISS principle`), because you want to connect the FET`s 3 pins directly into a connecting block, not have to build a full `bells and whistles` circuit on a PCB!

When someone says something is "in the high side" this means for example as applied to the good old fashioned Horn or Hooter circuit, where one side of the hooter is connected to +12. The hooter is in the high side. The other side of the hooter is wired to the button, which completes the circuit to Ground. The button would be described as in the "Low Side". Take a different tack. what drives the LED Is it a Switch screwed into the Engine Block If so how many wires does Switch have Is one of these wires connect to ground Or maybe one connects to + 12V Or does the LED get driven from an ECU If so, could you measure the voltage of the LED, with respect to ground Do this by clipping your negative probe to ground and probe either side of the LED with the red probe.

🔗 External reference