Remote thermometer

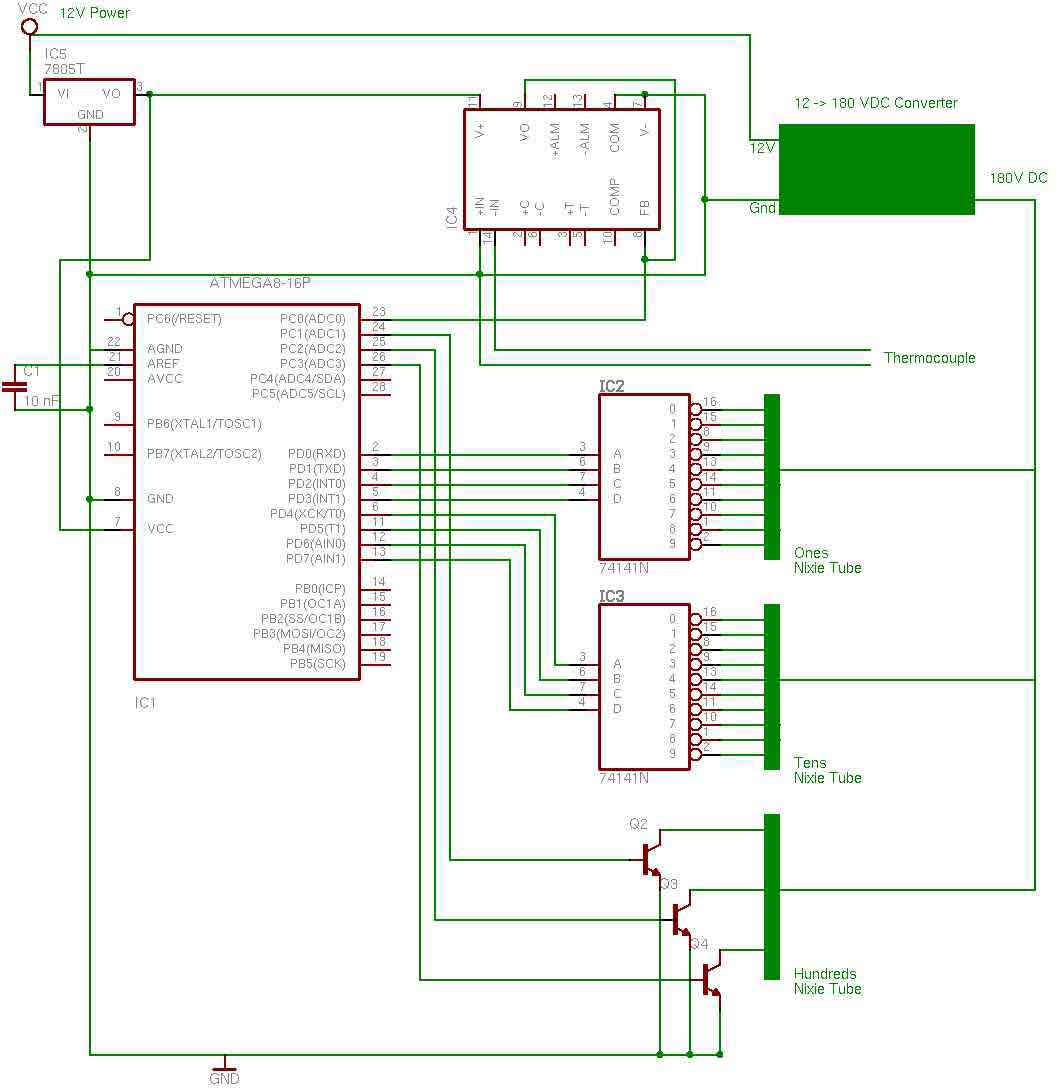

The low output impedance of a closed-loop operational amplifier (op amp) provides ideal immunity to line noise, while the offset voltage drift of the op amp serves as a temperature sensor. Utilizing the op amp in this manner requires no additional external components and offers the benefits of a hermetic package and consistent mechanical uniformity across units, which is advantageous for replacements. The offset drift of the op amp is amplified by the LTC1052 to drive a meter. A diode bridge connection enables the circuit to handle both positive and negative op amp temperature sensor offsets directly. The circuit is configured for an output range of +10°C to +40°C, although other temperature ranges can be accommodated easily. For calibration, the op amp sensor should be placed in a +10°C environment, and the 10°C trim should be adjusted to achieve the correct meter indication. Subsequently, the sensor should be moved to a +40°C environment, and the 40°C adjustment should be fine-tuned for the appropriate reading. This calibration procedure should be repeated until both temperature points are accurately fixed. Once calibrated, the circuit typically maintains an accuracy of ±20°C, even in high-noise environments.

The circuit employs a closed-loop op amp configuration, which significantly reduces the output impedance, thus enhancing its ability to reject noise and providing stable temperature readings. The op amp's inherent offset voltage drift is utilized as a primary sensing mechanism, allowing for precise temperature measurement without the need for additional components, thus simplifying the design and reducing potential points of failure. The LTC1052 is specifically chosen for its low offset voltage and drift characteristics, ensuring that the amplified output is stable and reliable.

The diode bridge connection is a critical feature that allows for versatility in the circuit, enabling it to accommodate both positive and negative offsets from the op amp's output. This flexibility is essential for applications where the temperature range might vary or where the sensor might be subjected to different environmental conditions.

Calibration of the circuit is straightforward and involves adjusting two trim pots to ensure accurate readings at the specified temperature points. This process guarantees that the system can adapt to variations in component tolerances and environmental influences, thereby maintaining accuracy. The final output of the circuit is designed to provide a clear and precise indication of temperature, making it suitable for applications in environments where high noise levels may otherwise interfere with sensor performance.

Overall, this op amp-based temperature sensing circuit exemplifies a robust and efficient design that leverages the strengths of operational amplifiers to deliver reliable performance across a range of operating conditions. The careful consideration of components and configuration ensures that the circuit remains functional and accurate, fulfilling the requirements of various applications in the field of electronics.The low output impedance of a closed loop op amp gives ideal line-noise immunity, while the op amp's offset voltage drift provides a temperature sensor. Using the op amp in this way requires no external components and has the additional advantages of a hermetic package and unit-to-unit mechanical uniformity if replacement is ever required.

The op amp's offset drift is amplified to drive the meter by the LTC1052. The diode bridge connection allows either positive or negative op amp temperature sensor offsets to interface directly with the circuit. In this case, the circuit is arranged for a + 10°C to +40°C output, although other ranges are easily accommodated.

To calibrate this circuit, subject the op amp sensor to a +10°C environment and adjust the 10 °C trim for an appropriate meter indication. Next, place the op amp sensor in a +40°C environment and trim the 40° C adjustment for the proper reading.

Repeat this procedure until both points are fixed. Once calibrated, this circuit will typically provide accuracy within ± 20 C, even in high noise environments. 🔗 External reference

The circuit employs a closed-loop op amp configuration, which significantly reduces the output impedance, thus enhancing its ability to reject noise and providing stable temperature readings. The op amp's inherent offset voltage drift is utilized as a primary sensing mechanism, allowing for precise temperature measurement without the need for additional components, thus simplifying the design and reducing potential points of failure. The LTC1052 is specifically chosen for its low offset voltage and drift characteristics, ensuring that the amplified output is stable and reliable.

The diode bridge connection is a critical feature that allows for versatility in the circuit, enabling it to accommodate both positive and negative offsets from the op amp's output. This flexibility is essential for applications where the temperature range might vary or where the sensor might be subjected to different environmental conditions.

Calibration of the circuit is straightforward and involves adjusting two trim pots to ensure accurate readings at the specified temperature points. This process guarantees that the system can adapt to variations in component tolerances and environmental influences, thereby maintaining accuracy. The final output of the circuit is designed to provide a clear and precise indication of temperature, making it suitable for applications in environments where high noise levels may otherwise interfere with sensor performance.

Overall, this op amp-based temperature sensing circuit exemplifies a robust and efficient design that leverages the strengths of operational amplifiers to deliver reliable performance across a range of operating conditions. The careful consideration of components and configuration ensures that the circuit remains functional and accurate, fulfilling the requirements of various applications in the field of electronics.The low output impedance of a closed loop op amp gives ideal line-noise immunity, while the op amp's offset voltage drift provides a temperature sensor. Using the op amp in this way requires no external components and has the additional advantages of a hermetic package and unit-to-unit mechanical uniformity if replacement is ever required.

The op amp's offset drift is amplified to drive the meter by the LTC1052. The diode bridge connection allows either positive or negative op amp temperature sensor offsets to interface directly with the circuit. In this case, the circuit is arranged for a + 10°C to +40°C output, although other ranges are easily accommodated.

To calibrate this circuit, subject the op amp sensor to a +10°C environment and adjust the 10 °C trim for an appropriate meter indication. Next, place the op amp sensor in a +40°C environment and trim the 40° C adjustment for the proper reading.

Repeat this procedure until both points are fixed. Once calibrated, this circuit will typically provide accuracy within ± 20 C, even in high noise environments. 🔗 External reference