Reverse Engineering a 1.5 inch Photoframe

These small devices featured a 1.5-inch 128x128 color TFT display, USB connectivity, batteries, and 16 Mbytes of storage capable of holding approximately 140 pictures. They were inexpensive, prompting the purchase of several units for potential repurposing. An examination of eBay listings indicated that these devices are quite common, suggesting that many may share identical internal components. Among the three frames acquired, two were equipped with LCDs labeled FTM144D01N, while the third bore the label LC12802. Despite the different markings, both models appeared functionally identical. A challenge encountered was the lack of available information regarding the displays online; the only reference found indicated that the FTM144D01N utilizes the ILI9163 LCD driver IC from ILITEK. With multiple units available, one photo frame was left intact while the screen was removed from another for analysis, enabling control of the latter on a breadboard. Care was taken to use side cutters to detach the Li-Po battery, ensuring insulation of the positive wire to prevent short-circuiting. The battery is a 3.7V Li-ion 120mAh cell, which can be utilized in other projects. The circuit board was then secured in a vice, and excess solder was removed using solder wick. A soldering iron heated to approximately 340°C was employed to melt the solder, allowing for the LCD to be gently twisted free from the circuit board. The connector for the LCD was examined, revealing 27 connections with several unused. The connector measured approximately 22mm, resulting in a pitch of about 0.8mm, which is typical for displays. Research into datasheets for similar ILI9163-based displays indicated that these LCDs typically utilize an 8 or 16-bit parallel interface and include five control lines: RESET, WR, RD, RS, and CS. Additionally, there are two power lines (Vdd and Gnd) and two for the backlight (Anode and Cathode). Testing the working photo frames with a multimeter confirmed that pins 1 and 2 correspond to Vdd and Gnd, while pin 26 was identified as the backlight Cathode and pin 27 as the backlight Anode. The analysis showed that eight pins were grouped together, suggesting they form the data bus (DB0:7), confirming the LCD operates on an 8-bit parallel interface. Five remaining pins matched the expected control pins. A reset button on the back of the photo frame facilitated the identification of the RESET line (pin 9) by observing the signal drop with an oscilloscope. Determining the other control pins required more effort; however, using a dual-channel oscilloscope to compare signals with the ILI9163 datasheet helped identify pin 7 as the RD pin, which maintained a constant 3.3V, indicating its role in read/write selection.

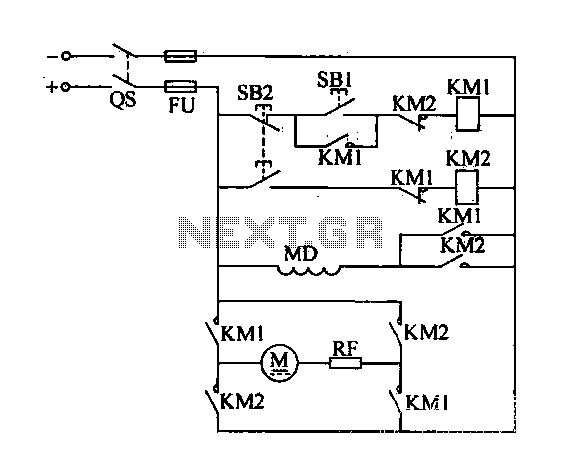

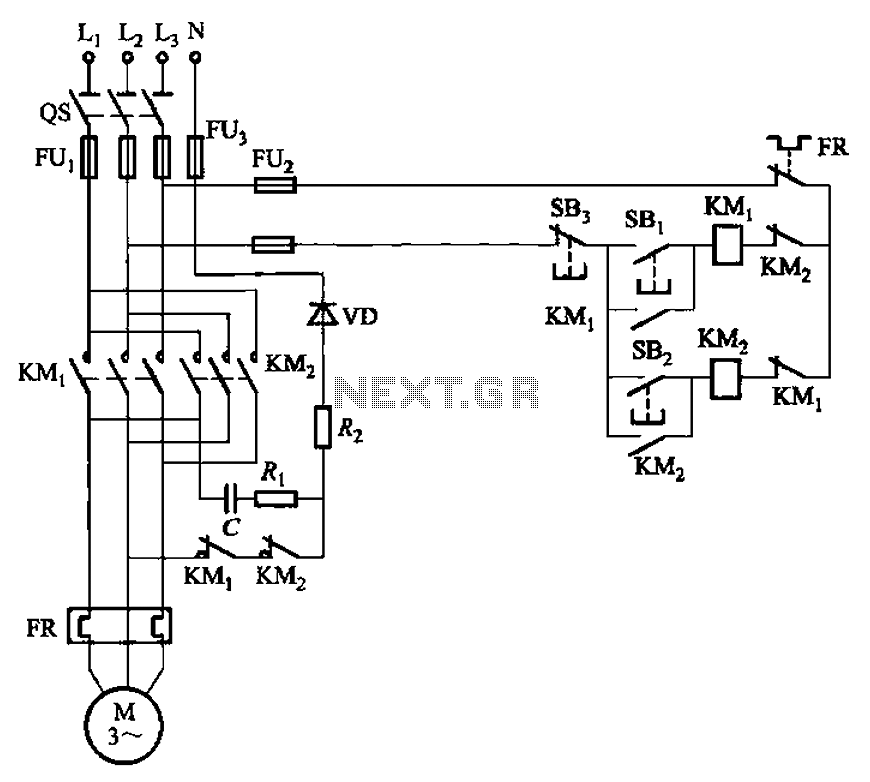

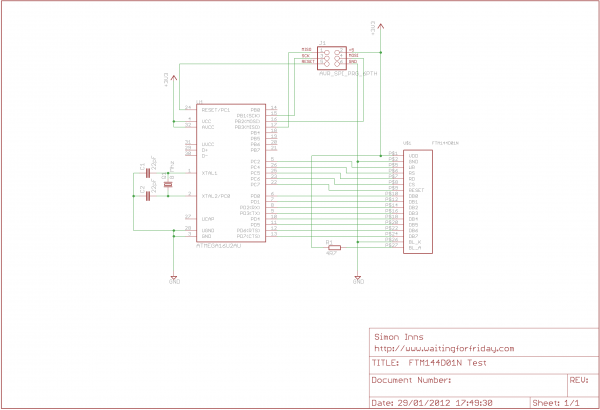

The electronic schematic of the described device can be organized into several key components: the TFT display, the control interface, the power supply, and the connections to the microcontroller. The TFT display, driven by the ILI9163, interfaces using an 8-bit data bus, which consists of eight data lines (DB0 to DB7) connected to corresponding GPIO pins on the microcontroller. The control lines include RESET, WR, RD, RS, and CS, each linked to specific GPIO pins, facilitating communication and command execution between the microcontroller and the display.

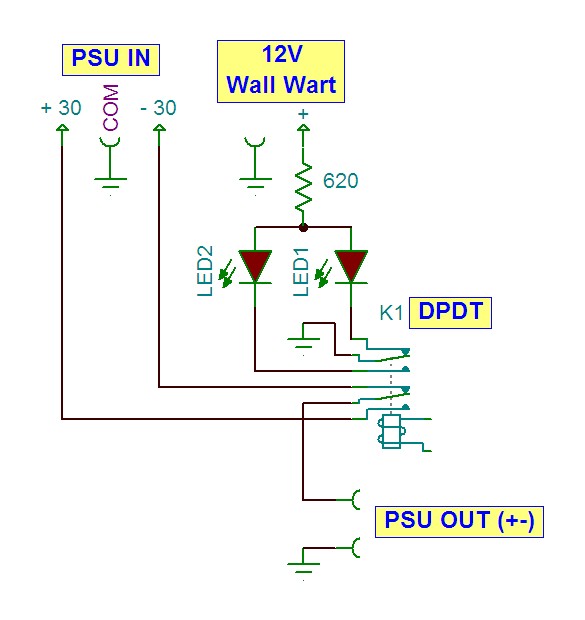

Powering the circuit involves a 3.7V Li-ion battery connected to the Vdd and Gnd pins of the display. The backlight is powered through the Anode and Cathode connections, allowing for illumination when required. The schematic should illustrate the power management, ensuring that the battery is protected from over-discharge and short-circuit conditions, possibly incorporating a battery management IC.

For the control logic, the microcontroller must be configured to handle the timing and signaling required for the display operation. This involves setting up registers for data transmission, as well as managing the read and write operations through the RD and WR lines. The RESET line must be utilized to initialize the display, ensuring it is in a known state before any commands are sent.

Overall, the schematic should represent a clear layout of the connections, including the necessary decoupling capacitors for power stability, and any additional components required for interfacing, such as pull-up resistors on the control lines if needed. This detailed schematic serves as a foundation for further development and experimentation with the repurposed photo frame displays.These little devices had a 1. 5 inch 128x128 colour TFT as well as USB, batteries and 16 Mbytes of storage for around 140 pictures. Best of all they were very cheap, so I purchased a few to see if they could be re-purposed into something useful.

Looking on ebay it seems these devices are common-place and it wouldn`t surprise me if most are internally identical Here is the box for one of the frames I bought: Out of the three I bought two had LCDs marked FTM144D01N and the other had the marking LC12802. 2, however both models looked functionally identical. The issue I found was that there was no available information on the display via Google, the only reference I found was that the FTM144D01N was based on the ILI9163 LCD driver IC from ILITEK.

Since I had more that one, I decided to leave one photo frame intact and remove the screen from the other. This would allow me to analyse the working frame whilst attempting to control the other on the breadboard.

Use a pair of side cutters to remove the Li-Po battery. Make sure you insulate the positive wire once cut so you don`t short the battery. The battery is a 3. 7V Li-ion 120mAh cell which is very useful for other projects. Next place the circuit board in a vice and use the wick to remove the excess solder. Simply heat the soldering iron to about 340C and then place the braid over the connector (partly on the board and partly on the ribbon) then apply the flat soldering tip for a short time to remove the solder. Once that`s done you hold the LCD in one hand and run the soldering iron across the ribbon whilst gently twisting the LCD free from the circuit.

The ribbon should come away easily. The first step to reverse engineering the LCD connections is to simply look at the connector itself. As can be seen in the following picture the ribbon has 27 connections of which many are simply not connected. I`ve marked the unused connections in red: The ruler placed under the ribbon shows that the connector is 22mm approximately.

This means that the connector pitch is 22/27 = 0. 81; this gives us a connector pitch of 0. 8mm (which is pretty typical for a display). From looking at datasheets for other similar ILI9163 based displays it can be seen that the LCDs are typically 8 or 16 bit parallel interfaces and have 5 control lines: RESET, WR, RD, RS and CS. In addition there are 2 power lines (Vdd and Gnd) and 2 power lines (Anode and Cathode) for the display backlight.

Using a multimeter on the working photo frames showed that pins 1 and 2 are Vdd and Gnd and that pin 26 was the backlight Cathode (positive) and 27 was the backlight Anode (negative). From the picture above you can also see that there are 8 pins which are all separated by unconnected pins, they also all go to the same group of tracks into the LCD.

From that you can easily infer that pins 10, 12, 14, 16, 18, 20, 22 and 24 are the DB0:7 data-bus. This means the LCD is a 8-bit parallel interface. This leaves 5 pins unaccounted for which (thankfully) matches with the expected number of control pins. The photo frame had a small reset button on the back so identifying the RESET line was as simple as pressing the reset switch and seeing which line dropped using an oscilloscope; this was pin 9.

Finding the rest of the control pins was a little more difficult, using just trial and error would take a long time. Since the ILI9163 data-sheet had some signalling diagrams I decided to compare the pins using a dual-channel oscilloscope to see if they could be identified.

Pin 7 was at a constant 3. 3Vs in the working photo frame so that was most likely the RD pin since that is the read/write selection (and the photo-frame only needs to write to the display). The data-sheet information showed that during operation the WR and CS lines would follow each other closely with the CS

🔗 External reference

The electronic schematic of the described device can be organized into several key components: the TFT display, the control interface, the power supply, and the connections to the microcontroller. The TFT display, driven by the ILI9163, interfaces using an 8-bit data bus, which consists of eight data lines (DB0 to DB7) connected to corresponding GPIO pins on the microcontroller. The control lines include RESET, WR, RD, RS, and CS, each linked to specific GPIO pins, facilitating communication and command execution between the microcontroller and the display.

Powering the circuit involves a 3.7V Li-ion battery connected to the Vdd and Gnd pins of the display. The backlight is powered through the Anode and Cathode connections, allowing for illumination when required. The schematic should illustrate the power management, ensuring that the battery is protected from over-discharge and short-circuit conditions, possibly incorporating a battery management IC.

For the control logic, the microcontroller must be configured to handle the timing and signaling required for the display operation. This involves setting up registers for data transmission, as well as managing the read and write operations through the RD and WR lines. The RESET line must be utilized to initialize the display, ensuring it is in a known state before any commands are sent.

Overall, the schematic should represent a clear layout of the connections, including the necessary decoupling capacitors for power stability, and any additional components required for interfacing, such as pull-up resistors on the control lines if needed. This detailed schematic serves as a foundation for further development and experimentation with the repurposed photo frame displays.These little devices had a 1. 5 inch 128x128 colour TFT as well as USB, batteries and 16 Mbytes of storage for around 140 pictures. Best of all they were very cheap, so I purchased a few to see if they could be re-purposed into something useful.

Looking on ebay it seems these devices are common-place and it wouldn`t surprise me if most are internally identical Here is the box for one of the frames I bought: Out of the three I bought two had LCDs marked FTM144D01N and the other had the marking LC12802. 2, however both models looked functionally identical. The issue I found was that there was no available information on the display via Google, the only reference I found was that the FTM144D01N was based on the ILI9163 LCD driver IC from ILITEK.

Since I had more that one, I decided to leave one photo frame intact and remove the screen from the other. This would allow me to analyse the working frame whilst attempting to control the other on the breadboard.

Use a pair of side cutters to remove the Li-Po battery. Make sure you insulate the positive wire once cut so you don`t short the battery. The battery is a 3. 7V Li-ion 120mAh cell which is very useful for other projects. Next place the circuit board in a vice and use the wick to remove the excess solder. Simply heat the soldering iron to about 340C and then place the braid over the connector (partly on the board and partly on the ribbon) then apply the flat soldering tip for a short time to remove the solder. Once that`s done you hold the LCD in one hand and run the soldering iron across the ribbon whilst gently twisting the LCD free from the circuit.

The ribbon should come away easily. The first step to reverse engineering the LCD connections is to simply look at the connector itself. As can be seen in the following picture the ribbon has 27 connections of which many are simply not connected. I`ve marked the unused connections in red: The ruler placed under the ribbon shows that the connector is 22mm approximately.

This means that the connector pitch is 22/27 = 0. 81; this gives us a connector pitch of 0. 8mm (which is pretty typical for a display). From looking at datasheets for other similar ILI9163 based displays it can be seen that the LCDs are typically 8 or 16 bit parallel interfaces and have 5 control lines: RESET, WR, RD, RS and CS. In addition there are 2 power lines (Vdd and Gnd) and 2 power lines (Anode and Cathode) for the display backlight.

Using a multimeter on the working photo frames showed that pins 1 and 2 are Vdd and Gnd and that pin 26 was the backlight Cathode (positive) and 27 was the backlight Anode (negative). From the picture above you can also see that there are 8 pins which are all separated by unconnected pins, they also all go to the same group of tracks into the LCD.

From that you can easily infer that pins 10, 12, 14, 16, 18, 20, 22 and 24 are the DB0:7 data-bus. This means the LCD is a 8-bit parallel interface. This leaves 5 pins unaccounted for which (thankfully) matches with the expected number of control pins. The photo frame had a small reset button on the back so identifying the RESET line was as simple as pressing the reset switch and seeing which line dropped using an oscilloscope; this was pin 9.

Finding the rest of the control pins was a little more difficult, using just trial and error would take a long time. Since the ILI9163 data-sheet had some signalling diagrams I decided to compare the pins using a dual-channel oscilloscope to see if they could be identified.

Pin 7 was at a constant 3. 3Vs in the working photo frame so that was most likely the RD pin since that is the read/write selection (and the photo-frame only needs to write to the display). The data-sheet information showed that during operation the WR and CS lines would follow each other closely with the CS

🔗 External reference