RGB LED Strip Circuit with Arduino

This document outlines the assembly of a circuit designed to pulse width modulate (PWM) a high-power RGB LED strip and program an Arduino to cycle through various colors. The term "high power" refers to a voltage range of 9-12 volts. The assembly process includes mounting a transistor onto a heatsink. Soldering instructions are not provided, as many RGB LED strips come with leads, and numerous tutorials are available for that purpose. Clear and straightforward language will be used to explain the circuit, recognizing the challenges faced by beginners in this field. For those new to Arduino, it is important to note that each output has a current limit of 40mA, meaning components cannot draw more than this amount from each channel. Using a water analogy, the voltage represents pump pressure, while the current represents the flow of electrons, measured in milliamps (mA). To support a load requiring more than 40mA at 5V, a microcontroller will control a transistor, which provides power from an external source, such as a battery. RGB LED strips consist of three LEDs in series, which can be cut at designated junctions, ensuring connection points are left on both halves. Understanding the difference between series and parallel circuits is essential for powering the RGB LED strip with 9-12V. In series, supply voltages and necessary currents are additive. For instance, since an average RGB LED requires 3.3V and 60mA (with each color channel drawing 20mA), a strip of three RGB LEDs will require approximately 9.9V. The specific strip referenced operates between 9-12V, but it is crucial to consult the product datasheet to avoid damaging components. Not all RGB LED strips function within this voltage range, such as Adafruit's digitally addressable RGB LED strip. These strips are common anode, meaning they share a positive terminal. A significant takeaway is the power limitation of the Arduino. The subsequent section on using a transistor can be applied to various components (e.g., motors, solenoids, servos) that require more than 40mA at 5V. A heatsink is essential for dissipating heat to prevent components from overheating, melting connections, or becoming unsoldered. This is particularly important when using a 7805 voltage regulator, which outputs a steady 5V to the microcontroller and generates significant heat. This approach is preferred due to concerns about the Arduino SMD voltage regulator's reliability, especially on Pro Minis, despite the Arduino Uno datasheet stating that the input voltage can reach 20V. The assembly process involves applying heatsink compound to the transistor to enhance thermal conductivity, followed by securing a nylon washer and nut onto the heatsink.

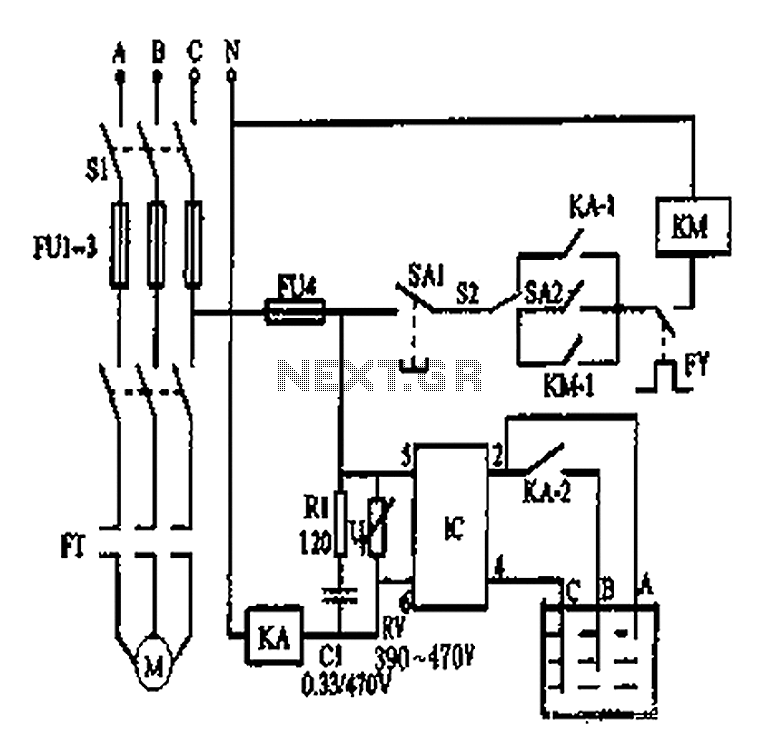

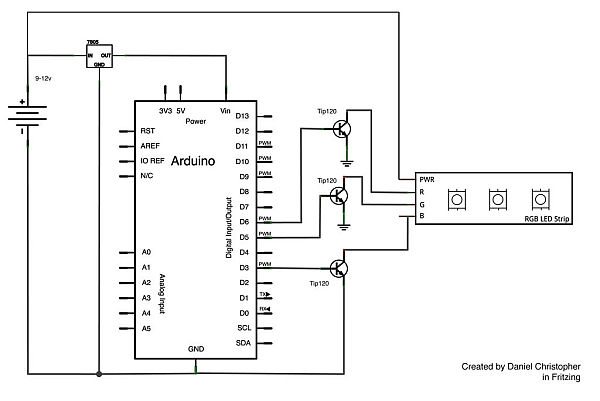

The circuit schematic will include the following components: an Arduino microcontroller, a transistor (such as a MOSFET) for controlling the LED strip, a heatsink for the transistor, a 7805 voltage regulator for providing a stable 5V supply to the microcontroller, and the RGB LED strip itself. The Arduino will be programmed to generate PWM signals that modulate the brightness of each color channel (red, green, and blue) of the LED strip. The transistor will act as a switch, allowing the higher voltage (9-12V) from the power supply to drive the LED strip while being controlled by the low-voltage signals from the Arduino.

Connections will be made as follows: the Arduino's PWM output pins will connect to the gate of the transistor, while the source will connect to ground. The drain will connect to the negative side of the LED strip, with the positive side connected to the external power supply. The 7805 voltage regulator will be connected to the power supply to ensure a constant 5V output to the Arduino. The heatsink will be mounted on the transistor to dissipate heat generated during operation, ensuring reliable performance. Proper attention to component ratings and thermal management will lead to a successful and efficient PWM control system for the RGB LED strip.This Instructable covers the assembly of a circuit capable of PWM-ing ( pulse width modulating ) a high-power RGB LED strip and programming an Arduino to cycle through a range of colors. In this context, high power is 9-12 volts. I will discuss how to mount a transistor to a heatsink and assemble the circuit. I will not go into soldering as som e of the RGB LED strip comes with leads (and there is no shortage of great tutorials out there). Also, I will use the most plain, non-jargony language possible to explain the circuit because I know how frustrating it can be to learn this stuff. If you are new to Arduino and are wondering why more than a few LEDs or other components like motors won`t activate when functions are called in the code, its because each output has a current limit of 40mA.

In other words, a component cannot draw more than 40mA of current from each channel. To refer to the water analogy of electronics, the pump pressure is 5V, and the amount of water is the number of electrons (measured in Amps, or in our case, a much smaller amount milliamps, mA). To accommodate a load that requires more current than 40mA at 5V, we will use our microcontroller to control a transistor, which will provide a component with power from an external source (the battery).

Without getting too technical, its worth knowing that individual strips are made up of 3 LEDs in series which can be cut with clippers at any junction. If you want to cut the strip at any point, just be sure to leave connection points on each halve. To understand how the RGB LED strip can be powered with 9-12V, you need to know the difference between circuits in series vs.

parallel (this page has a simple explanation with great illustrations, and there is a popular Instructable that covers wiring LEDs in series & parallel ). Basically, when LED`s are connected in series, the supply voltages and necessary current are added together (respectively).

For example, since an average RGB LED requires 3. 3 V and 60mA (at full brightness; each color channel draws 20mA, so R-G-B all on at same time is 20 x 3 = 60mA), each strip of 3 RGB LEDs will require approximately 9. 9V ( the strip I`m using from Jameco can be powered between 9-12V. Be sure to look at your product`s datasheet to prevent frying your components. Not all RGB LED strip is powered in the 9-12V range, such as Adafruit`s digitally addressable RGB LED strip ).

One more thing, these strips are common anode, meaning the LEDs share a positive terminal ( read about anode vs. cathode ). Perhaps the greatest take-away is the power limitation of the Arduino. The next section which shows how to use a transistor can be applied to all sorts of other components (ex.

motors, solenoids, servos) that require more than 40mA at 5V. A heat sink s function is to dissipate heat so components don`t fry, melt connections/become un-soldered, or become too hot to touch. This is really important if you`re using a 7805 for voltage regulation, which I`m also doing in this circuit.

The 7805 will output a steady 5V to the microcontroller and dissipate quite a bit of heat. I like to do this because I don`t trust the Arduino SMD voltage regulator, especially on ProMinis which I use frequently (even thought the Arduino Uno datasheet says the input voltage can be as high as 20V). This part is pretty straight-forward. Apply some heat sink compound to the transistor (first image in this series) and then put the nylon washer on screw on then through the transistor (second).

The compound increases thermal conductivity, which aids in the dissipation process. Lastly, fasten the nut to the back of the heat sink. 🔗 External reference

The circuit schematic will include the following components: an Arduino microcontroller, a transistor (such as a MOSFET) for controlling the LED strip, a heatsink for the transistor, a 7805 voltage regulator for providing a stable 5V supply to the microcontroller, and the RGB LED strip itself. The Arduino will be programmed to generate PWM signals that modulate the brightness of each color channel (red, green, and blue) of the LED strip. The transistor will act as a switch, allowing the higher voltage (9-12V) from the power supply to drive the LED strip while being controlled by the low-voltage signals from the Arduino.

Connections will be made as follows: the Arduino's PWM output pins will connect to the gate of the transistor, while the source will connect to ground. The drain will connect to the negative side of the LED strip, with the positive side connected to the external power supply. The 7805 voltage regulator will be connected to the power supply to ensure a constant 5V output to the Arduino. The heatsink will be mounted on the transistor to dissipate heat generated during operation, ensuring reliable performance. Proper attention to component ratings and thermal management will lead to a successful and efficient PWM control system for the RGB LED strip.This Instructable covers the assembly of a circuit capable of PWM-ing ( pulse width modulating ) a high-power RGB LED strip and programming an Arduino to cycle through a range of colors. In this context, high power is 9-12 volts. I will discuss how to mount a transistor to a heatsink and assemble the circuit. I will not go into soldering as som e of the RGB LED strip comes with leads (and there is no shortage of great tutorials out there). Also, I will use the most plain, non-jargony language possible to explain the circuit because I know how frustrating it can be to learn this stuff. If you are new to Arduino and are wondering why more than a few LEDs or other components like motors won`t activate when functions are called in the code, its because each output has a current limit of 40mA.

In other words, a component cannot draw more than 40mA of current from each channel. To refer to the water analogy of electronics, the pump pressure is 5V, and the amount of water is the number of electrons (measured in Amps, or in our case, a much smaller amount milliamps, mA). To accommodate a load that requires more current than 40mA at 5V, we will use our microcontroller to control a transistor, which will provide a component with power from an external source (the battery).

Without getting too technical, its worth knowing that individual strips are made up of 3 LEDs in series which can be cut with clippers at any junction. If you want to cut the strip at any point, just be sure to leave connection points on each halve. To understand how the RGB LED strip can be powered with 9-12V, you need to know the difference between circuits in series vs.

parallel (this page has a simple explanation with great illustrations, and there is a popular Instructable that covers wiring LEDs in series & parallel ). Basically, when LED`s are connected in series, the supply voltages and necessary current are added together (respectively).

For example, since an average RGB LED requires 3. 3 V and 60mA (at full brightness; each color channel draws 20mA, so R-G-B all on at same time is 20 x 3 = 60mA), each strip of 3 RGB LEDs will require approximately 9. 9V ( the strip I`m using from Jameco can be powered between 9-12V. Be sure to look at your product`s datasheet to prevent frying your components. Not all RGB LED strip is powered in the 9-12V range, such as Adafruit`s digitally addressable RGB LED strip ).

One more thing, these strips are common anode, meaning the LEDs share a positive terminal ( read about anode vs. cathode ). Perhaps the greatest take-away is the power limitation of the Arduino. The next section which shows how to use a transistor can be applied to all sorts of other components (ex.

motors, solenoids, servos) that require more than 40mA at 5V. A heat sink s function is to dissipate heat so components don`t fry, melt connections/become un-soldered, or become too hot to touch. This is really important if you`re using a 7805 for voltage regulation, which I`m also doing in this circuit.

The 7805 will output a steady 5V to the microcontroller and dissipate quite a bit of heat. I like to do this because I don`t trust the Arduino SMD voltage regulator, especially on ProMinis which I use frequently (even thought the Arduino Uno datasheet says the input voltage can be as high as 20V). This part is pretty straight-forward. Apply some heat sink compound to the transistor (first image in this series) and then put the nylon washer on screw on then through the transistor (second).

The compound increases thermal conductivity, which aids in the dissipation process. Lastly, fasten the nut to the back of the heat sink. 🔗 External reference