Rotate a stepper motor using a computer

Designing and implementing this circuit was an exciting endeavor. The design of the interface involved learning how to control a device from a computer. A parallel port cable was utilized for this purpose, enabling instant control of the stepper motor. Given that the designed circuit operates correctly, it can be concluded that the experiment was successfully completed.

The circuit described involves the use of a parallel port interface to control a stepper motor. The parallel port serves as a communication interface between the computer and the stepper motor driver circuit. In this setup, the computer sends control signals through the parallel port, which are then interpreted by the driver circuit to manage the stepper motor's movement.

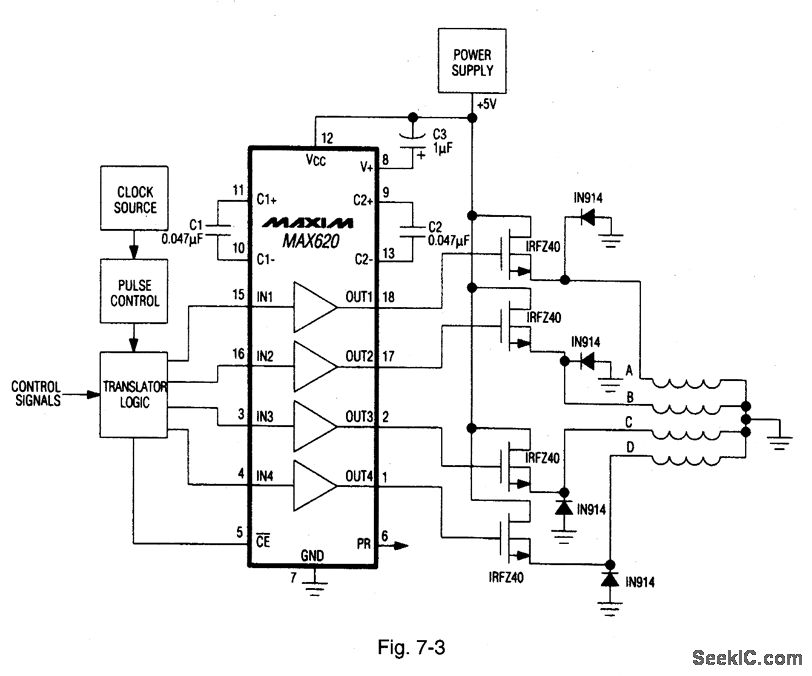

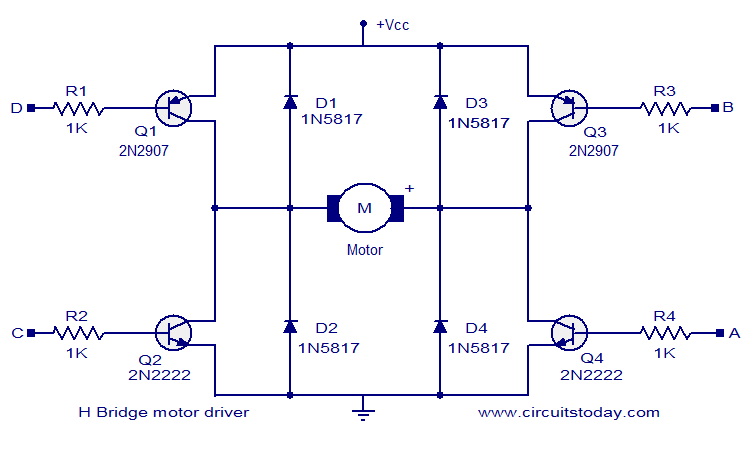

The design of the circuit typically includes a microcontroller or a dedicated stepper motor driver IC that receives the signals from the parallel port. The driver IC translates these signals into appropriate voltage levels and current requirements to energize the motor coils sequentially, allowing for precise control of the motor's rotation and position.

Connections in the circuit would include the parallel port pins connected to the input pins of the driver IC. The stepper motor itself is connected to the output pins of the driver, which are responsible for energizing the motor coils in the correct order. Power supply considerations are also critical, as the stepper motor often requires a higher voltage and current than what the parallel port can provide. An external power supply is usually incorporated to meet these requirements.

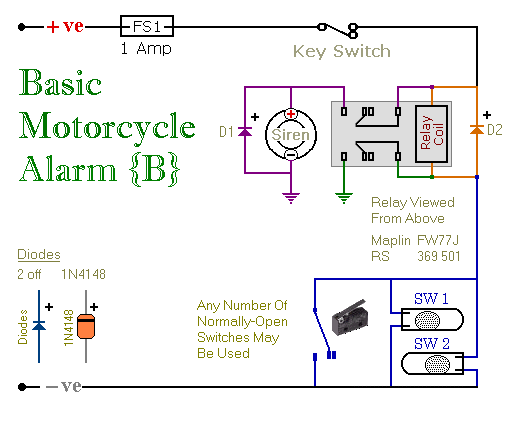

In addition, it is essential to include protective components such as diodes to prevent back EMF generated by the motor from damaging the driver circuit. Proper grounding and signal integrity measures should also be implemented to ensure reliable operation.

Overall, this circuit exemplifies the principles of digital communication, motor control, and interfacing between a computer and external hardware, demonstrating a successful application of electronics in a practical scenario.Designing and implementing this circuit was really very exciting for us. When designing the interface, we learn things of controlling a device from a computer. We use parallelport cable for this purpose and instantly controlled the rotation of the steppermotor. Since, our designed circuit works properly, so it can be said that we have completed ou r experiment successfully. 🔗 External reference

The circuit described involves the use of a parallel port interface to control a stepper motor. The parallel port serves as a communication interface between the computer and the stepper motor driver circuit. In this setup, the computer sends control signals through the parallel port, which are then interpreted by the driver circuit to manage the stepper motor's movement.

The design of the circuit typically includes a microcontroller or a dedicated stepper motor driver IC that receives the signals from the parallel port. The driver IC translates these signals into appropriate voltage levels and current requirements to energize the motor coils sequentially, allowing for precise control of the motor's rotation and position.

Connections in the circuit would include the parallel port pins connected to the input pins of the driver IC. The stepper motor itself is connected to the output pins of the driver, which are responsible for energizing the motor coils in the correct order. Power supply considerations are also critical, as the stepper motor often requires a higher voltage and current than what the parallel port can provide. An external power supply is usually incorporated to meet these requirements.

In addition, it is essential to include protective components such as diodes to prevent back EMF generated by the motor from damaging the driver circuit. Proper grounding and signal integrity measures should also be implemented to ensure reliable operation.

Overall, this circuit exemplifies the principles of digital communication, motor control, and interfacing between a computer and external hardware, demonstrating a successful application of electronics in a practical scenario.Designing and implementing this circuit was really very exciting for us. When designing the interface, we learn things of controlling a device from a computer. We use parallelport cable for this purpose and instantly controlled the rotation of the steppermotor. Since, our designed circuit works properly, so it can be said that we have completed ou r experiment successfully. 🔗 External reference