line follower tutorial based atmega16 l298 motor driver

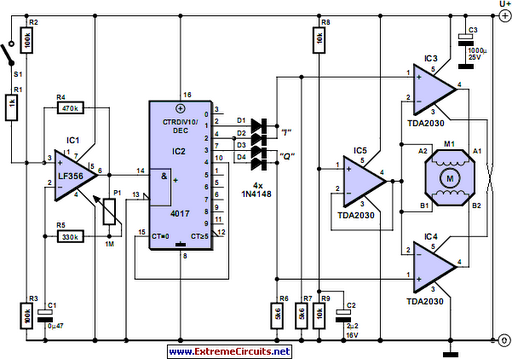

This line follower robot utilizes the following components: eight phototransistor proximity sensors, an ATMega16 microcontroller, an L298 motor driver, and is programmed using the C programming language.

The line follower robot is designed to navigate along a designated path by detecting and following lines on the ground. The system employs eight phototransistor proximity sensors strategically placed to enhance detection accuracy. These sensors are capable of identifying contrasts between the line color and the surface, allowing the robot to make real-time adjustments to its movement.

The heart of the robot is the ATMega16 microcontroller, which processes the input signals from the phototransistor sensors. This microcontroller is programmed in the C programming language, enabling the implementation of algorithms that determine the robot's direction based on sensor readings. The software logic typically involves comparing the values from the sensors to decide whether the robot should move forward, turn left, or turn right.

The L298 motor driver is utilized to control the motors that drive the robot's wheels. This driver can control the speed and direction of the motors based on the signals received from the ATMega16 microcontroller. It is capable of driving two DC motors, allowing for differential steering, which is essential for maneuvering the robot along curves and corners of the line.

Overall, the combination of these components allows the line follower robot to operate efficiently and reliably, making it a practical example of robotics and automation in action. The integration of sensors, microcontroller, and motor driver, along with the programming in C, showcases the fundamental principles of electronic circuit design and embedded systems.This line follower robot use the following module: Proximity sensor: 8 pcs of phototransistors; ATMega16 Microcontroller; Motor driver L298; C Programming language 🔗 External reference

The line follower robot is designed to navigate along a designated path by detecting and following lines on the ground. The system employs eight phototransistor proximity sensors strategically placed to enhance detection accuracy. These sensors are capable of identifying contrasts between the line color and the surface, allowing the robot to make real-time adjustments to its movement.

The heart of the robot is the ATMega16 microcontroller, which processes the input signals from the phototransistor sensors. This microcontroller is programmed in the C programming language, enabling the implementation of algorithms that determine the robot's direction based on sensor readings. The software logic typically involves comparing the values from the sensors to decide whether the robot should move forward, turn left, or turn right.

The L298 motor driver is utilized to control the motors that drive the robot's wheels. This driver can control the speed and direction of the motors based on the signals received from the ATMega16 microcontroller. It is capable of driving two DC motors, allowing for differential steering, which is essential for maneuvering the robot along curves and corners of the line.

Overall, the combination of these components allows the line follower robot to operate efficiently and reliably, making it a practical example of robotics and automation in action. The integration of sensors, microcontroller, and motor driver, along with the programming in C, showcases the fundamental principles of electronic circuit design and embedded systems.This line follower robot use the following module: Proximity sensor: 8 pcs of phototransistors; ATMega16 Microcontroller; Motor driver L298; C Programming language 🔗 External reference