schematic heater fan controller

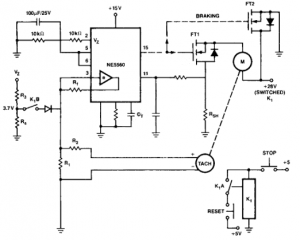

The Heater Fan Controller is designed around the PIC12F675 microcontroller. It reads a 10k linear potentiometer and generates appropriately timed pulses to control the DC motor that operates the fan. The lowest setting completely cuts off the power. This device functions as a variable speed control for the heater blower in a car. It is powered from the existing wiring and connects using just two wires, or it can be connected to a 12-volt device with a maximum current of 10 amps. The circuit is relatively simple; the wire to the blower motor (either high or low side) is cut, and a connection is made to the circuit with the more positive side at the top connection. A diode and a 100µF capacitor ensure a steady 12 volts, as the Pulse Width Modulation (PWM) scheme maintains a minimum 'off' time within the power cycle.

The Heater Fan Controller utilizes a PIC12F675 microcontroller, which is a versatile and compact device suitable for embedded applications. The microcontroller interfaces with a 10k linear potentiometer, allowing users to adjust the fan speed based on their preferences. The PWM technique employed in this circuit effectively modulates the voltage supplied to the DC motor, enabling smooth control of the fan's speed.

In operation, when the potentiometer is turned to its lowest setting, the microcontroller recognizes this input and cuts off power to the fan, ensuring no energy is wasted when the fan is not needed. As the potentiometer is adjusted higher, the microcontroller generates PWM signals that vary the duty cycle, thus controlling the average voltage and current supplied to the fan motor. This method not only provides efficient speed control but also minimizes heat generation in the circuit components.

The circuit design is straightforward, facilitating easy integration into existing automotive systems. The connection to the blower motor is made by cutting the wire and inserting the circuit in-line, ensuring that the positive side of the motor is connected correctly to maintain proper functionality. The inclusion of a diode and a 100µF capacitor serves to stabilize the voltage supply, preventing fluctuations that could affect motor performance. The diode protects against reverse voltage, while the capacitor smooths out any voltage spikes, ensuring that the fan operates reliably under varying conditions.

Overall, this Heater Fan Controller represents an effective solution for managing heater blower speeds in automotive applications, providing users with the flexibility to adjust airflow according to their needs while maintaining system efficiency and reliability.The Heater Fan Controller built around PIC12F675 microcontroller. It reads the (10k) linear potentiometer and generates appropriately timed pulses to control the DC motor running the fan. The extreme low position cuts the power entirely. This device work as a variable speed control for the heater blower in a car. The project is powered from the ex isting wiring and connects with just 2 wires. Or you can connect it to 12 volt device up to 10 amps. "The circuit is relatively simple. The wire to the blower motor (either high or low side) is cut and connection is made to the circuit with the more positive side at the top connection. The diode and 100uf capacitor always provide full 12 volts because the Pulse Width Modulation scheme always provides a minimum `off` time of the power cycle, " said Mondo.

🔗 External reference

The Heater Fan Controller utilizes a PIC12F675 microcontroller, which is a versatile and compact device suitable for embedded applications. The microcontroller interfaces with a 10k linear potentiometer, allowing users to adjust the fan speed based on their preferences. The PWM technique employed in this circuit effectively modulates the voltage supplied to the DC motor, enabling smooth control of the fan's speed.

In operation, when the potentiometer is turned to its lowest setting, the microcontroller recognizes this input and cuts off power to the fan, ensuring no energy is wasted when the fan is not needed. As the potentiometer is adjusted higher, the microcontroller generates PWM signals that vary the duty cycle, thus controlling the average voltage and current supplied to the fan motor. This method not only provides efficient speed control but also minimizes heat generation in the circuit components.

The circuit design is straightforward, facilitating easy integration into existing automotive systems. The connection to the blower motor is made by cutting the wire and inserting the circuit in-line, ensuring that the positive side of the motor is connected correctly to maintain proper functionality. The inclusion of a diode and a 100µF capacitor serves to stabilize the voltage supply, preventing fluctuations that could affect motor performance. The diode protects against reverse voltage, while the capacitor smooths out any voltage spikes, ensuring that the fan operates reliably under varying conditions.

Overall, this Heater Fan Controller represents an effective solution for managing heater blower speeds in automotive applications, providing users with the flexibility to adjust airflow according to their needs while maintaining system efficiency and reliability.The Heater Fan Controller built around PIC12F675 microcontroller. It reads the (10k) linear potentiometer and generates appropriately timed pulses to control the DC motor running the fan. The extreme low position cuts the power entirely. This device work as a variable speed control for the heater blower in a car. The project is powered from the ex isting wiring and connects with just 2 wires. Or you can connect it to 12 volt device up to 10 amps. "The circuit is relatively simple. The wire to the blower motor (either high or low side) is cut and connection is made to the circuit with the more positive side at the top connection. The diode and 100uf capacitor always provide full 12 volts because the Pulse Width Modulation scheme always provides a minimum `off` time of the power cycle, " said Mondo.

🔗 External reference