SCR Phase Control Speed Control/Dimmer

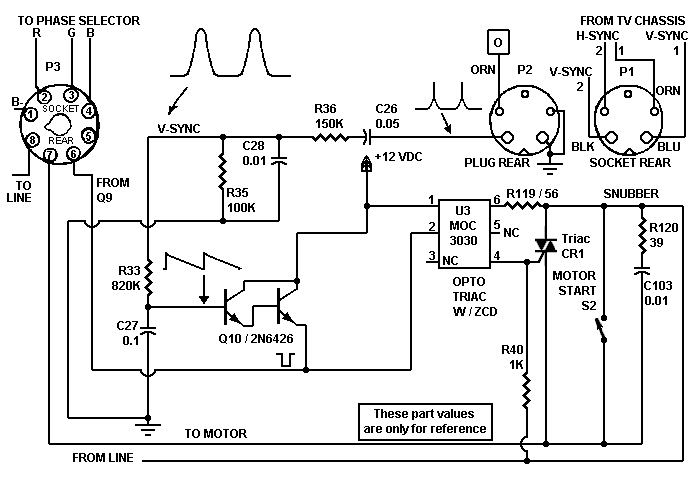

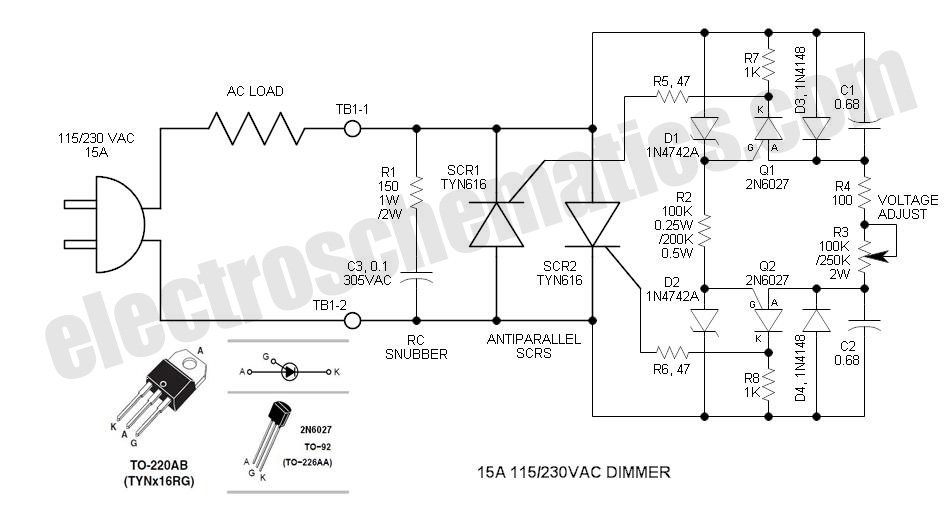

The DIAC is a 28V bidirectional trigger device commonly used in inexpensive phase control applications. Its trigger voltage is relatively high for 115VAC phase control. In the past, a similar low voltage trigger device known as a Shockley diode existed, but it is now obsolete. The 2N6027 Programmable Unijunction Transistor (PUT) can perform a similar function, although it is polarity sensitive and therefore not suitable for TRIAC control. However, two PUT trigger circuits can be utilized for anti-parallel SCRs, allowing control of both trigger circuits with a single potentiometer for identical half-cycle control. To ensure optimal balance, the zeners and capacitors must be matched, with a tolerance of 5% or better. The operation of the PUT is straightforward; its threshold voltage is programmable and can be set to trigger at low voltages using 12V zeners. When the PUT anode voltage exceeds the gate voltage by one junction drop, the PUT activates and discharges the timing capacitor into the SCR gate circuit, resetting when the AC line voltage reverses. A PUT relaxation oscillator flasher circuit is available for experimentation. Typical DIAC-controlled TRIAC dimmers exhibit a snap-on effect at minimum voltage when adjustments are made slowly. This phenomenon occurs due to the lagging phase relationship of the AC voltage across the timing capacitor before reaching the DIAC threshold. The timing circuit in this control avoids this issue by resetting the capacitor voltage each half-cycle through reverse diodes across the timing capacitors. From a thermal perspective, splitting the output current reduces device current and lowers thermal resistance to the ambient. SCRs can handle a maximum junction temperature (Tj) of 125 °C, while TRIACs are limited to 110 °C. SCRs also have higher current ratings, making them more robust. Additionally, the circuit absorbs reactive energy when either SCR stops conducting, preventing high voltage spikes caused by inductance in series circuits. The snubber circuit provides a pathway for this current, and it also acts as a resistive load for high-frequency line noise and transients, which can inadvertently turn on an SCR. A ceramic composition resistor is specified for handling voltage transients, while a polypropylene capacitor is used for better reliability at 230VAC. A Quencharc device, rated for 125VAC, combines both resistor and capacitor functions. The load voltage can be observed increasing in phase, with the baseline being somewhat indistinct due to the low power load (7.5W lamp). The snubber reactance results in a significant voltage drop across the lamp. The gate current indicates a peak of approximately 200mA with a time constant of about 32 µs, primarily influenced by the inductance of the shunt resistor.

The DIAC and PUT circuits discussed are integral to various phase control applications, particularly in dimmers and motor speed controllers. The DIAC serves as a reliable trigger mechanism, allowing for the precise control of AC voltage. The use of a single potentiometer to control both halves of the AC cycle through anti-parallel SCRs enhances the circuit's efficiency and user-friendliness, ensuring consistent performance across different load conditions.

In designing these circuits, careful attention to component selection is crucial. The matching of zeners and capacitors not only ensures balanced operation but also enhances the stability and reliability of the circuit. The choice of a polypropylene capacitor over polyester is particularly important in high-voltage applications, where reliability is paramount. Furthermore, the implementation of a snubber circuit is essential for protecting sensitive components from voltage spikes and transients, which can result from the rapid switching actions inherent in AC circuits.

Overall, the combination of DIAC, PUT, and SCR technologies provides a robust framework for controlling AC power in a variety of applications, offering advantages in thermal management, reliability, and operational efficiency. The design considerations outlined here are vital for engineers looking to implement effective phase control solutions.The DIAC is a 28V bidirectional (bilateral) trigger device that is used on virtually all inexpensive phase controls. The trigger voltage is somewhat high for phase control of 115VAC. Years ago, there was a similar low voltage (6 to 8V) trigger device called a Shockley diode. Unfortunately, these never caught on and today are EXTINCT. The 2N6027 Pr ogrammable Unijunction Transistor (PUT) can perform a similar function, but is polarity sensitive so it does not lend itself to TRIAC control. However, if two such PUT trigger circuits are employed for anti-parallel SCRs, some interesting things are apparent.

Most important is the ability to control both trigger circuits with a single potentiometer so that both half-cycles are controlled identically. To obtain best balance, the zeners and capacitors must be matched. Both zeners and capacitors are specified for a tolerance of 5%, but I selected mine for better than 1% with my DMM.

Purchase a few additional components so that you may obtain a good match. PUT operation is simple. Its threshold voltage is programmable so that it can trigger at low voltages. In this circuit it is set via the 12V zeners. When the PUT anode voltage exceeds the gate voltage by one junction drop, the PUT fires and dumps the timing capacitor into the SCR gate circuit. It resets when the AC line voltage reverses. I made a PUT relaxation oscillator flasher circuit that you may wish to experiment with: The typical DIAC controlled TRIAC dimmer tends to snap-on at the minimum voltage when the adjustment is slowly increased.

After snap-on, the voltage may be reduced if desired. The snap-on phenomenon is caused by the lagging phase relationship of the AC voltage signal that appears across the timing capacitor before the DIAC threshold is reached. After it initially fires, the timing starts at line voltage zero crossing. The timing circuit in this control completely avoids this problem by resetting the capacitor voltage each half-cycle via reverse diodes across the two timing capacitors.

Thermally, there are numerous advantages. Splitting the output current in half reduces the device current significantly and provides a much lower thermal resistance to the ambient. Also, SCRs are rated for a maximum Tj of 125 °, while TRIACs may be limited to only 110 °C. Then, of course, SCRs are available in current ratings extending to hundreds of amps ” well over ten times that of the largest TRIACs.

SCRs are simply more rugged. First it provides a circuit to absorb reactive energy when either SCR recovers (stops conducting current). As you may know, a rectifier conducts current in the reverse direction for a short period of time (e.

g. 5 µS) when it becomes reversed biased. The flow of this current stops abruptly and any series circuit inductance then causes the generation of a transient voltage (spike). The snubber is a place for this current to go so it cannot develop a high voltage. Second, it provides a resistive load for high frequency line noise and transients. Such noise or transients can potentially cause an SCR to turn on for a half-cycle. One common source of transients is simply the power switch when it closes. Film resistors are not robust in handling voltage transients so I specified a ceramic composition resistor.

Polyester capacitors have poor reliability at 230VAC, so I specified a polypropylene capacitor that is AC rated. In my circuit, I used a Quencharc device that contains both resistor and capacitor ” it is AC rated for 125VAC.

The load voltage is easy to see here as it increases in phase. The base line is rather indistinct due to the low power load used (7. 5W lamp) ” the snubber reactance causes significant voltage drop across the lamp. The gate current indicates a peak current of about 200mA and a time constant of about 32 µS ” essentially 47 © * 0. 68 µf. The leading edge spike is caused by the inductance of the 1 © shunt resistor used. Th 🔗 External reference

The DIAC and PUT circuits discussed are integral to various phase control applications, particularly in dimmers and motor speed controllers. The DIAC serves as a reliable trigger mechanism, allowing for the precise control of AC voltage. The use of a single potentiometer to control both halves of the AC cycle through anti-parallel SCRs enhances the circuit's efficiency and user-friendliness, ensuring consistent performance across different load conditions.

In designing these circuits, careful attention to component selection is crucial. The matching of zeners and capacitors not only ensures balanced operation but also enhances the stability and reliability of the circuit. The choice of a polypropylene capacitor over polyester is particularly important in high-voltage applications, where reliability is paramount. Furthermore, the implementation of a snubber circuit is essential for protecting sensitive components from voltage spikes and transients, which can result from the rapid switching actions inherent in AC circuits.

Overall, the combination of DIAC, PUT, and SCR technologies provides a robust framework for controlling AC power in a variety of applications, offering advantages in thermal management, reliability, and operational efficiency. The design considerations outlined here are vital for engineers looking to implement effective phase control solutions.The DIAC is a 28V bidirectional (bilateral) trigger device that is used on virtually all inexpensive phase controls. The trigger voltage is somewhat high for phase control of 115VAC. Years ago, there was a similar low voltage (6 to 8V) trigger device called a Shockley diode. Unfortunately, these never caught on and today are EXTINCT. The 2N6027 Pr ogrammable Unijunction Transistor (PUT) can perform a similar function, but is polarity sensitive so it does not lend itself to TRIAC control. However, if two such PUT trigger circuits are employed for anti-parallel SCRs, some interesting things are apparent.

Most important is the ability to control both trigger circuits with a single potentiometer so that both half-cycles are controlled identically. To obtain best balance, the zeners and capacitors must be matched. Both zeners and capacitors are specified for a tolerance of 5%, but I selected mine for better than 1% with my DMM.

Purchase a few additional components so that you may obtain a good match. PUT operation is simple. Its threshold voltage is programmable so that it can trigger at low voltages. In this circuit it is set via the 12V zeners. When the PUT anode voltage exceeds the gate voltage by one junction drop, the PUT fires and dumps the timing capacitor into the SCR gate circuit. It resets when the AC line voltage reverses. I made a PUT relaxation oscillator flasher circuit that you may wish to experiment with: The typical DIAC controlled TRIAC dimmer tends to snap-on at the minimum voltage when the adjustment is slowly increased.

After snap-on, the voltage may be reduced if desired. The snap-on phenomenon is caused by the lagging phase relationship of the AC voltage signal that appears across the timing capacitor before the DIAC threshold is reached. After it initially fires, the timing starts at line voltage zero crossing. The timing circuit in this control completely avoids this problem by resetting the capacitor voltage each half-cycle via reverse diodes across the two timing capacitors.

Thermally, there are numerous advantages. Splitting the output current in half reduces the device current significantly and provides a much lower thermal resistance to the ambient. Also, SCRs are rated for a maximum Tj of 125 °, while TRIACs may be limited to only 110 °C. Then, of course, SCRs are available in current ratings extending to hundreds of amps ” well over ten times that of the largest TRIACs.

SCRs are simply more rugged. First it provides a circuit to absorb reactive energy when either SCR recovers (stops conducting current). As you may know, a rectifier conducts current in the reverse direction for a short period of time (e.

g. 5 µS) when it becomes reversed biased. The flow of this current stops abruptly and any series circuit inductance then causes the generation of a transient voltage (spike). The snubber is a place for this current to go so it cannot develop a high voltage. Second, it provides a resistive load for high frequency line noise and transients. Such noise or transients can potentially cause an SCR to turn on for a half-cycle. One common source of transients is simply the power switch when it closes. Film resistors are not robust in handling voltage transients so I specified a ceramic composition resistor.

Polyester capacitors have poor reliability at 230VAC, so I specified a polypropylene capacitor that is AC rated. In my circuit, I used a Quencharc device that contains both resistor and capacitor ” it is AC rated for 125VAC.

The load voltage is easy to see here as it increases in phase. The base line is rather indistinct due to the low power load used (7. 5W lamp) ” the snubber reactance causes significant voltage drop across the lamp. The gate current indicates a peak current of about 200mA and a time constant of about 32 µS ” essentially 47 © * 0. 68 µf. The leading edge spike is caused by the inductance of the 1 © shunt resistor used. Th 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713