self powered fast battery tester

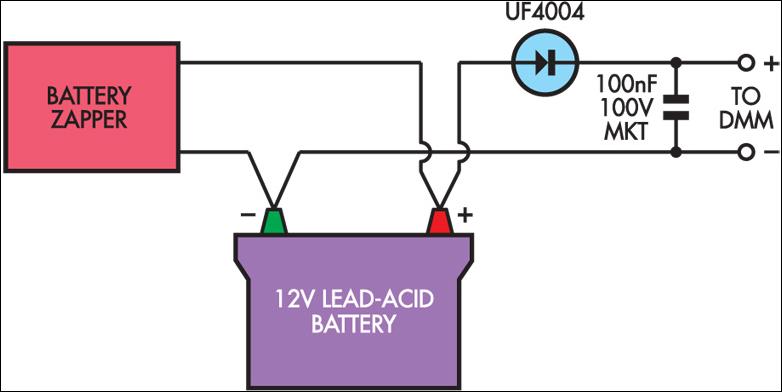

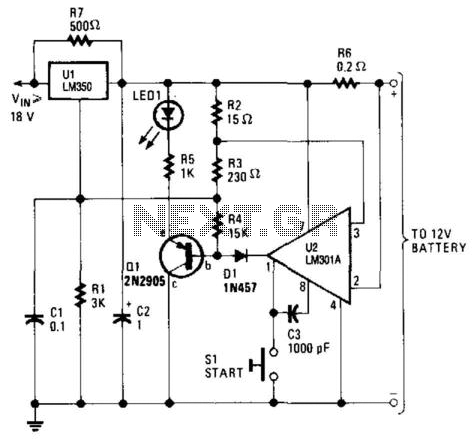

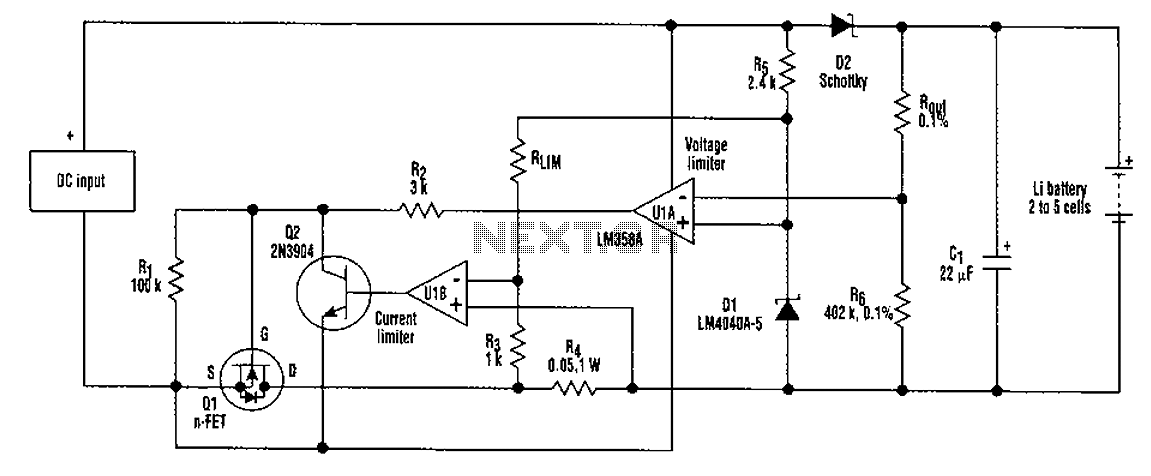

This circuit performs a rapid battery test without requiring an external power supply or costly moving-coil voltmeters. It features two testing ranges: when switch SW1 is configured as indicated in the circuit diagram, the device is capable of testing batteries ranging from 3V to 15V. When SW1 is toggled to the alternate position, it can test only 1.5V cells.

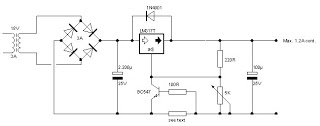

The circuit utilizes a simple design that leverages a few key components to facilitate efficient battery testing. The main components typically include resistors, a switch (SW1), and a measurement device, which can be a digital multimeter or an analog meter, depending on the user's preference.

In the first configuration, where SW1 is set to test batteries from 3V to 15V, the circuit connects the battery under test to a voltage divider network formed by the resistors. This voltage divider scales the battery voltage down to a level that is safe for measurement. The output of the voltage divider is then routed to the measurement device, allowing the user to observe the battery voltage directly.

In the second configuration, designed for testing 1.5V cells, the circuit bypasses the voltage divider or utilizes a different resistor value to accommodate the lower voltage. This ensures that the measurement device can accurately read the voltage of the 1.5V battery without damaging the components or providing erroneous readings.

The simplicity of this circuit design makes it highly effective for quick battery tests, eliminating the need for complex setups or expensive equipment. It is particularly useful for hobbyists and professionals alike who require a straightforward solution for assessing battery health and voltage levels efficiently.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It has two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1.5V cells can be tested.. 🔗 External reference

The circuit utilizes a simple design that leverages a few key components to facilitate efficient battery testing. The main components typically include resistors, a switch (SW1), and a measurement device, which can be a digital multimeter or an analog meter, depending on the user's preference.

In the first configuration, where SW1 is set to test batteries from 3V to 15V, the circuit connects the battery under test to a voltage divider network formed by the resistors. This voltage divider scales the battery voltage down to a level that is safe for measurement. The output of the voltage divider is then routed to the measurement device, allowing the user to observe the battery voltage directly.

In the second configuration, designed for testing 1.5V cells, the circuit bypasses the voltage divider or utilizes a different resistor value to accommodate the lower voltage. This ensures that the measurement device can accurately read the voltage of the 1.5V battery without damaging the components or providing erroneous readings.

The simplicity of this circuit design makes it highly effective for quick battery tests, eliminating the need for complex setups or expensive equipment. It is particularly useful for hobbyists and professionals alike who require a straightforward solution for assessing battery health and voltage levels efficiently.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It has two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1.5V cells can be tested.. 🔗 External reference