Self-powered Fast Battery-Tester

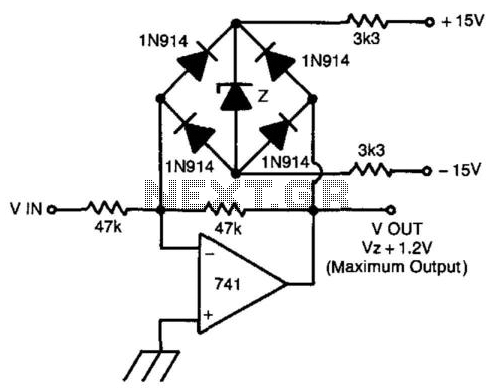

This circuit performs a rapid battery test without requiring an external power supply or costly moving-coil voltmeters. It features two ranges: when switch SW1 is set as indicated in the circuit diagram, the device can test batteries ranging from 3V to 15V. When SW1 is switched to the alternate position, it is capable of testing only 1.5V cells. To utilize the circuit, place the battery under test in an appropriate holder or connect it to the circuit. Allow several seconds for capacitor C8 to reach full charge. LED D1 will illuminate very dimly only when a new battery is present; otherwise, it remains off. Press switch P1 while monitoring LED D7. If D7 remains completely off, the battery is likely in excellent condition. If D7 lights up brightly for a few seconds, the battery is weak. If D7 glows dimly for a few seconds, the battery is still functional but not new. For suspected completely discharged 1.5V cells, a more reliable test can be conducted by connecting two 1.5V batteries in series and then performing the 3V test. FET Q1 serves as a constant current generator, providing bias to LED D1 and the base of Q2. This configuration allows D1 to illuminate at a consistent intensity, regardless of the battery voltage within the 3V to 15V range, while Q2 applies a constant load of approximately 120mA to the battery when P1 is engaged. IC1 operates as a square wave generator oscillating at roughly 3kHz. IC2 functions as an inverter, driving diodes D2-D6 and capacitors C4-C7 in an anti-phase manner to achieve voltage multiplication. Capacitor C8 is charged by the elevated voltage, and resistors R8-R10 create a voltage divider to bias the base of Q3. When P1 is not pressed, a minimal load is applied to the battery under test, keeping LED D7 off. When P1 is pressed, a 120mA load is imposed on the battery. If the battery is not fully charged, its output voltage begins to decline; when this voltage drops 0.6V below the nominal battery voltage, the emitter of Q3 becomes more negative than the base, causing the transistor to conduct and LED D7 to illuminate. This condition persists for a few seconds, corresponding to the time required for C8 to adjust its voltage to the new level, which is proportional to the loaded battery voltage. If the battery is in good condition, its output voltage remains above the threshold under a 120mA load, keeping LED D7 off. When testing 1.5V batteries, the circuit involving Q1, Q2, D1, R1, and R2 is ineffective at this voltage level, so a 150mA load is applied to the battery under test through a 10-ohm resistor R3 after switching SW1A. The biasing of Q3 is also adjusted via SW1B.

This battery testing circuit is designed to provide a straightforward and efficient means of assessing battery health across different voltage ranges. The dual-range functionality allows for flexibility in testing both standard 3V to 15V batteries and 1.5V cells, enhancing its usability in various applications. The use of FET Q1 as a constant current source ensures that the testing conditions remain stable, providing accurate readings regardless of the battery's initial voltage level. The inclusion of a square wave generator (IC1) and an inverter (IC2) enables effective voltage multiplication, ensuring that the circuit operates reliably even when testing lower voltage batteries.

The feedback mechanism involving Q3 and LED D7 offers a clear visual indication of the battery's condition, making it user-friendly. The gradual response of LED D7 to voltage fluctuations provides insight into the battery's performance under load, which is critical for determining its usability in practical applications. Additionally, the circuit's design allows for quick tests, minimizing the time required to assess battery health, which is particularly beneficial in environments where rapid diagnostics are essential.

Overall, this circuit represents an effective solution for battery testing, integrating essential components to deliver reliable performance while maintaining ease of use. Its design principles can be adapted for further enhancements or modifications, depending on specific testing requirements or battery types.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It has two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1. 5V cells can be tested. * Switch SW1 in the position opposite to that shown in th e circuit diagram. * Place the battery under test in a suitable holder or clip it to the circuit. * Wait some seconds in order to let C8 reach its full charge. * LED D1 illuminates very weakly only in presence of a new battery, otherwise is off. * Press P1 and keep an eye to LED D7. If D7 remains fully off the battery can be in very good state. * If D7 illuminates brightly for a few seconds, the battery is weak. * If D7 illuminates weakly for a few seconds, the battery is still good but is not new. * If you are suspecting a 1. 5V cell to be completely discharged, a better test can be made wiring two 1. 5V batteries in series, then running the 3V test. FET Q1 provides a constant current generator biasing LED D1 and Q2 Base. In this manner D1 illuminates at a constant intensity, independent of battery voltage from 3 to 15V and Q2 (when P1 is closed) applies a constant current load of about 120mA to the battery. IC1 is a square wave generator oscillating at about 3KHz. IC2 acts as an inverter and drives, together with IC1 but in anti-phase, Diodes D2-D6 and Capacitors C4-C7, obtaining a voltage multiplication.

C8 is charged by this raised voltage and R8-R10 form a voltage divider biasing the Base of Q3. When P1 is open, a very light load is applied to the battery under test and Q3 Base is biased in order to maintain LED D7 in the off state. Closing P1, a 120mA load is applied to the battery under test. If the battery is not fully charged, its output voltage starts reducing: when this voltage falls 0. 6V below the battery nominal voltage, Q3 Emitter becomes more negative than the Base, transistor is hard biased and D7 illuminates.

Obviously, this state of affairs lasts a few seconds: the time spent by C8 to reduce its initial voltage to the new one, proportional to the voltage of the loaded battery. If the battery under test is in a good charging state, its output voltage did not fall under a 120mA loading current, so LED D7 stays off.

When testing 1. 5V batteries, the circuit formed by Q1, Q2, D1, R1 & R2 doesn`t work well at this supply voltage, so a 150mA load current is applied to the BUT by means of the 10 Ohm resistor R3 after switching SW1A. Q3 bias is also changed via SW1B. 🔗 External reference

This battery testing circuit is designed to provide a straightforward and efficient means of assessing battery health across different voltage ranges. The dual-range functionality allows for flexibility in testing both standard 3V to 15V batteries and 1.5V cells, enhancing its usability in various applications. The use of FET Q1 as a constant current source ensures that the testing conditions remain stable, providing accurate readings regardless of the battery's initial voltage level. The inclusion of a square wave generator (IC1) and an inverter (IC2) enables effective voltage multiplication, ensuring that the circuit operates reliably even when testing lower voltage batteries.

The feedback mechanism involving Q3 and LED D7 offers a clear visual indication of the battery's condition, making it user-friendly. The gradual response of LED D7 to voltage fluctuations provides insight into the battery's performance under load, which is critical for determining its usability in practical applications. Additionally, the circuit's design allows for quick tests, minimizing the time required to assess battery health, which is particularly beneficial in environments where rapid diagnostics are essential.

Overall, this circuit represents an effective solution for battery testing, integrating essential components to deliver reliable performance while maintaining ease of use. Its design principles can be adapted for further enhancements or modifications, depending on specific testing requirements or battery types.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It has two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1. 5V cells can be tested. * Switch SW1 in the position opposite to that shown in th e circuit diagram. * Place the battery under test in a suitable holder or clip it to the circuit. * Wait some seconds in order to let C8 reach its full charge. * LED D1 illuminates very weakly only in presence of a new battery, otherwise is off. * Press P1 and keep an eye to LED D7. If D7 remains fully off the battery can be in very good state. * If D7 illuminates brightly for a few seconds, the battery is weak. * If D7 illuminates weakly for a few seconds, the battery is still good but is not new. * If you are suspecting a 1. 5V cell to be completely discharged, a better test can be made wiring two 1. 5V batteries in series, then running the 3V test. FET Q1 provides a constant current generator biasing LED D1 and Q2 Base. In this manner D1 illuminates at a constant intensity, independent of battery voltage from 3 to 15V and Q2 (when P1 is closed) applies a constant current load of about 120mA to the battery. IC1 is a square wave generator oscillating at about 3KHz. IC2 acts as an inverter and drives, together with IC1 but in anti-phase, Diodes D2-D6 and Capacitors C4-C7, obtaining a voltage multiplication.

C8 is charged by this raised voltage and R8-R10 form a voltage divider biasing the Base of Q3. When P1 is open, a very light load is applied to the battery under test and Q3 Base is biased in order to maintain LED D7 in the off state. Closing P1, a 120mA load is applied to the battery under test. If the battery is not fully charged, its output voltage starts reducing: when this voltage falls 0. 6V below the battery nominal voltage, Q3 Emitter becomes more negative than the Base, transistor is hard biased and D7 illuminates.

Obviously, this state of affairs lasts a few seconds: the time spent by C8 to reduce its initial voltage to the new one, proportional to the voltage of the loaded battery. If the battery under test is in a good charging state, its output voltage did not fall under a 120mA loading current, so LED D7 stays off.

When testing 1. 5V batteries, the circuit formed by Q1, Q2, D1, R1 & R2 doesn`t work well at this supply voltage, so a 150mA load current is applied to the BUT by means of the 10 Ohm resistor R3 after switching SW1A. Q3 bias is also changed via SW1B. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713