sensor Arduino analog signal read problem

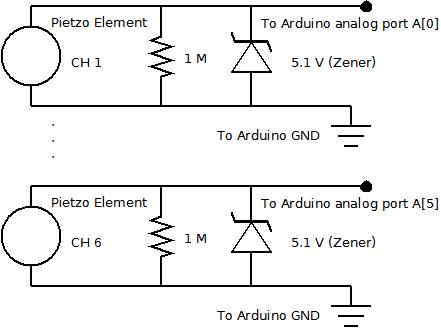

The piezo element is connected solely to Channel 1 (Arduino A[0] port). Channels 1 through 6 are linked to female mono jacks, with the ground (GND) wiring arranged in series from jacks 1, 2, and 3, continuing to the end of Channel 6 connected to the Arduino GND port. The recorded data includes several values, with indications of errors in channels 2, 3, 4, and 5. A constant integer for signal level is defined as 10, and a boolean threshold is initialized as false. The sensor readings for six channels are set up, and within the loop, the readings from analog pins A0 to A5 are captured. If any reading exceeds the defined signal level, the threshold is set to true, and the sensor readings are printed to the serial monitor.

The circuit design involves a piezo element connected to the first analog input of an Arduino microcontroller, specifically the A0 pin. This configuration allows the Arduino to monitor the piezo element's output, which can be used for various applications such as detecting vibrations or pressure changes. The remaining channels (A1 to A5) are set up to read from additional sensors or inputs, connected through female mono jacks. Each channel's ground connection is designed in a daisy-chain manner, ensuring that all channels share a common ground, which is critical for accurate sensor readings.

The software component of the system is structured to initialize an array for sensor readings and a boolean variable to track whether any reading exceeds a predefined threshold. The setup function establishes a serial communication link at a baud rate of 9600 bps, enabling real-time data transmission to a connected computer or display device. In the loop function, the code continuously reads values from the analog inputs, storing them in the sensor reading array. A for-loop iterates through the readings, checking if any value surpasses the defined signal level of 10. If this condition is met, the threshold variable is set to true, prompting the program to output the current sensor readings to the serial monitor.

This design allows for effective monitoring and analysis of multiple analog inputs, providing valuable data for applications ranging from simple sensor readings to more complex data logging and event-triggered actions based on sensor thresholds. The error messages indicate potential issues with the readings from certain channels, suggesting that further investigation may be needed to ensure reliable operation across all channels.The piezo element is only connected to Channel 1 (Arduino A[0] port). The channels Ch 1 Ch 6 are connected to female mono jacks and the ground(GND) wiring is in series from jack 1, 2 and 3 so on. till the Ch 6 end to the Arduino GND port. Taped 3 times 787 0 0 0 0 0 191 0 0 0 0 0 19 0 0 0 0 0 937 123 63 5 0 0 < ch2, ch3 ch4 ERROR !> 86 0 0 0 0

0 13 0 0 0 0 0 507 83 126 16 8 0 < ch2, ch3, ch4 ch5 ERROR !> 21 1 1 0 0 0 < ch2, ch3 ERROR !> 0 0 18 0 0 0 < ch3 ERROR !> const int singnalLevel = 10; boolean treshold = false; int sensorReading[6]; void setup() { Serial. begin(9600); } void loop() { int sensorReading[6] = {0, 0, 0, 0, 0, 0}; boolean treshold = false; sensorReading[0] = analogRead(A0); sensorReading[1] = analogRead(A1); sensorReading[2] = analogRead(A2); sensorReading[3] = analogRead(A3); sensorReading[4] = analogRead(A4); sensorReading[5] = analogRead(A5); for (int index = 0; index <= 5 ; index+) { if(sensorReading[index] > singnalLevel){ treshold = true; } } if(treshold){ for (int index = 0; index <= 5 ; index+) { Serial.

print(sensorReading[index]); Serial. print(" "); } Serial. println(); } delay(1); } 🔗 External reference

The circuit design involves a piezo element connected to the first analog input of an Arduino microcontroller, specifically the A0 pin. This configuration allows the Arduino to monitor the piezo element's output, which can be used for various applications such as detecting vibrations or pressure changes. The remaining channels (A1 to A5) are set up to read from additional sensors or inputs, connected through female mono jacks. Each channel's ground connection is designed in a daisy-chain manner, ensuring that all channels share a common ground, which is critical for accurate sensor readings.

The software component of the system is structured to initialize an array for sensor readings and a boolean variable to track whether any reading exceeds a predefined threshold. The setup function establishes a serial communication link at a baud rate of 9600 bps, enabling real-time data transmission to a connected computer or display device. In the loop function, the code continuously reads values from the analog inputs, storing them in the sensor reading array. A for-loop iterates through the readings, checking if any value surpasses the defined signal level of 10. If this condition is met, the threshold variable is set to true, prompting the program to output the current sensor readings to the serial monitor.

This design allows for effective monitoring and analysis of multiple analog inputs, providing valuable data for applications ranging from simple sensor readings to more complex data logging and event-triggered actions based on sensor thresholds. The error messages indicate potential issues with the readings from certain channels, suggesting that further investigation may be needed to ensure reliable operation across all channels.The piezo element is only connected to Channel 1 (Arduino A[0] port). The channels Ch 1 Ch 6 are connected to female mono jacks and the ground(GND) wiring is in series from jack 1, 2 and 3 so on. till the Ch 6 end to the Arduino GND port. Taped 3 times 787 0 0 0 0 0 191 0 0 0 0 0 19 0 0 0 0 0 937 123 63 5 0 0 < ch2, ch3 ch4 ERROR !> 86 0 0 0 0

0 13 0 0 0 0 0 507 83 126 16 8 0 < ch2, ch3, ch4 ch5 ERROR !> 21 1 1 0 0 0 < ch2, ch3 ERROR !> 0 0 18 0 0 0 < ch3 ERROR !> const int singnalLevel = 10; boolean treshold = false; int sensorReading[6]; void setup() { Serial. begin(9600); } void loop() { int sensorReading[6] = {0, 0, 0, 0, 0, 0}; boolean treshold = false; sensorReading[0] = analogRead(A0); sensorReading[1] = analogRead(A1); sensorReading[2] = analogRead(A2); sensorReading[3] = analogRead(A3); sensorReading[4] = analogRead(A4); sensorReading[5] = analogRead(A5); for (int index = 0; index <= 5 ; index+) { if(sensorReading[index] > singnalLevel){ treshold = true; } } if(treshold){ for (int index = 0; index <= 5 ; index+) { Serial.

print(sensorReading[index]); Serial. print(" "); } Serial. println(); } delay(1); } 🔗 External reference