servo tester

A servo tester circuit has been built as shown. The only observable action is for the servo to twitch when the power is switched on. There is no clear reason for its failure to operate correctly. Suggestions for troubleshooting are welcome. The circuit has not yet been constructed, so no comments can be made on its efficacy. Previous experience with servos in radio-controlled models, including aircraft and cars, indicates that servo twitching is often caused by interference, not necessarily from the circuit itself, but from external signals such as those from refrigerators when tested indoors and in close proximity. The servo may glitch and twitch if there is a fault in the receiver. Occasionally, the servo itself may be defective. Testing with another servo is recommended. The issue may stem from noise generated by external components or possibly from the circuit itself. Installing ceramic capacitors on small electric motors has proven effective in reducing excess noise that can affect servo performance. The author acknowledges their experience in radio-controlled aeromodelling and previous ownership of a model shop, asserting that the interference is not the cause of the twitch, which resembles the behavior observed when most standard RC receivers are powered on. The next step is unclear, but familiarity with integrated circuits exists, albeit this is the first use of a 555 timer. Assistance is sought regarding the circuit, specifically concerning the connection of the servo connector. Variations in servo connector designs may lead to compatibility issues. It is questioned whether the servo plug must be removed to connect it to the circuit, suggesting a potential oversight in the schematic. A solution is provided for connecting the servo: a female connector from an unused servo extension lead can be used, with the lead cut in half and soldered into the appropriate holes on the circuit board. Female-only leads are available from model shops or larger electronic suppliers. Differences in servo connections are acknowledged, particularly between Futaba and JR compatible leads, with the circuit indicating the correct layout: black (or brown) for negative, red for positive, and white (or yellow, orange) for signal. The positive lead is typically the center lead in a flat cable. It is noted that JR and Futaba plugs, while electrically compatible, are not physically identical. A small ridge on a Futaba plug can be carefully removed to allow it to fit either system, ensuring correct orientation. Some lesser-known brands use all-black leads, which are prone to issues. The only reliable method to identify these leads is to check against the manufacturer's receiver.

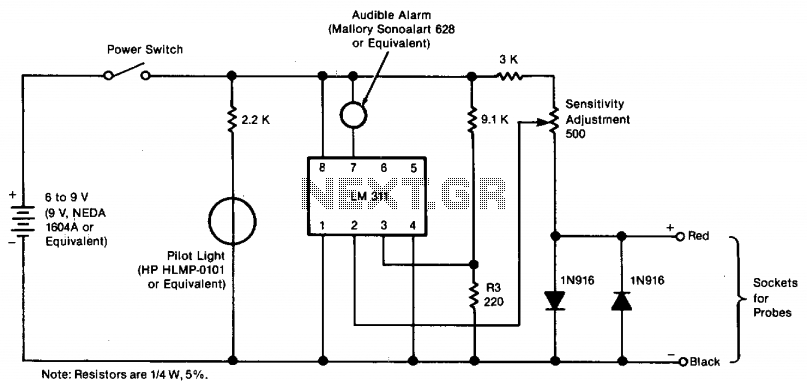

The servo tester circuit is designed to provide a simple means of testing servo motors by generating a control signal. The core component of the circuit is the 555 timer IC, configured in astable mode to produce a pulse-width modulated (PWM) signal. This PWM signal is responsible for controlling the position of the servo motor.

The circuit typically includes a power supply, often a battery or a regulated DC power source, which powers the 555 timer and the servo. The output of the 555 timer connects to the signal pin of the servo. The circuit may also incorporate capacitors to stabilize the power supply and reduce noise, which can interfere with the servo's operation.

In terms of connections, the servo motor usually has three wires: one for power (positive), one for ground (negative), and one for the signal. Proper wiring is essential to ensure that the servo receives the correct voltage and control signals. The polarity of the connections must be observed to prevent damage to the servo.

To further enhance the circuit's reliability, it may be beneficial to include bypass capacitors close to the power pins of the 555 timer and the servo. These capacitors can help filter out high-frequency noise that could cause erratic behavior in the servo.

In conclusion, while the circuit's basic operation is straightforward, attention to detail in assembly and component selection is crucial for optimal performance. Testing with an oscilloscope can help diagnose any issues by visualizing the PWM signal and ensuring it meets the required specifications for the servo being used.Built servo tester cicuit as shown - only action is for the servo to twitch when power switched on, cannot see any real reason why wont work - ideas anyone I haven`t built this circuit yet so I can`t comment on the circuits efficacy. I do have some experience of using servos in radio controlled models, both aircraft and cars. Whenever I have experienced servo twitch it has been caused by some form of interference, not necessarily from your circuit but signals from things like refrigerators and the like when tested indoors and in close proximity. The servo tends to glitch and twitch if their is a fault in the rx. Sometimes the servo itself can be faulty. Try another servo. My bet is that its noise from either external components or maybe the circuit itself. I have had to install ceramic capacitors to small electric motors before now to cut the excess noise that can affect a servo.

That`s my best guess, hope it helps or at least points you in the right direction. I haven`t built this circuit yet so I can`t comment on the circuits efficacy. I do have some experience of using servos in radio controlled models, both aircraft and cars. Whenever I have experienced servo twitch it has been caused by some form of interference, not necessarily from your circuit but signals from things like refrigerators and the like when tested indoors and in close proximity. The servo tends to glitch and twitch if their is a fault in the rx. Sometimes the servo itself can be faulty. Try another servo. My bet is that its noise from either external components or maybe the circuit itself. I have had to install ceramic capacitors to small electric motors before now to cut the excess noise that can affect a servo.

That`s my best guess, hope it helps or at least points you in the right direction. Konrad - thanks for the thought, but I am an experienced RC aeromodeller and in fact used to own my own model shop. I can guarantee that it is not IF causing the twitch which is exactly the same as when most standard RC RX`s are switched on.

I am at a loss as to next move, I do know how to handle IC`s but this is my first use of a 555 and need someone to point me in a likely direction - please note I have a scope available so can check on what really should be happening. I think this will be my next build. Perhaps you can help me with a question I have regarding the circuit. Into what and where exactly do you plug the servo connector From my experience these can be of a slightly different design, so one plug does not fit every rx.

Surely you don`t have to take the plug of the servo to get it into the circuit. Perhaps I`m missing something from the schematic. A case of `can`t see the wood for the trees`. Hi Konrad - I used a female connector from an unused servo extention lead - simply cut the lead in half and soldered the lead into the respective holes on my circuit board, (please note you can buy female only leads from the better model shops or one of the bigger electronic suppliers), I simply had a lead handy. You are correct saying that there are differences in some servo connections - if you are using either Futaba or JR compatible leads then the circuit shows the correct layout black(brown)= neg.

red=pos. white(yellow, orange)=signal. The positive is usually the centre lead in a flat cable. Also the JR and Futaba plugs are not physically identical even though they are electrically the same. I remove the small ridge on a Futaba plug carefully, it will then fit either system and you only have to make sure that it`s the right way round!

A few of the less popular brands use all black leads, personally I refused to stock these when I had my shop as they were more prone to problems - the only reliable way to check these black leads is to look at the same manufacturers RX and note which lead is which. Finally, if you haven`t got a suitable lead, then providing you are happy to remove the servo plug, 🔗 External reference

The servo tester circuit is designed to provide a simple means of testing servo motors by generating a control signal. The core component of the circuit is the 555 timer IC, configured in astable mode to produce a pulse-width modulated (PWM) signal. This PWM signal is responsible for controlling the position of the servo motor.

The circuit typically includes a power supply, often a battery or a regulated DC power source, which powers the 555 timer and the servo. The output of the 555 timer connects to the signal pin of the servo. The circuit may also incorporate capacitors to stabilize the power supply and reduce noise, which can interfere with the servo's operation.

In terms of connections, the servo motor usually has three wires: one for power (positive), one for ground (negative), and one for the signal. Proper wiring is essential to ensure that the servo receives the correct voltage and control signals. The polarity of the connections must be observed to prevent damage to the servo.

To further enhance the circuit's reliability, it may be beneficial to include bypass capacitors close to the power pins of the 555 timer and the servo. These capacitors can help filter out high-frequency noise that could cause erratic behavior in the servo.

In conclusion, while the circuit's basic operation is straightforward, attention to detail in assembly and component selection is crucial for optimal performance. Testing with an oscilloscope can help diagnose any issues by visualizing the PWM signal and ensuring it meets the required specifications for the servo being used.Built servo tester cicuit as shown - only action is for the servo to twitch when power switched on, cannot see any real reason why wont work - ideas anyone I haven`t built this circuit yet so I can`t comment on the circuits efficacy. I do have some experience of using servos in radio controlled models, both aircraft and cars. Whenever I have experienced servo twitch it has been caused by some form of interference, not necessarily from your circuit but signals from things like refrigerators and the like when tested indoors and in close proximity. The servo tends to glitch and twitch if their is a fault in the rx. Sometimes the servo itself can be faulty. Try another servo. My bet is that its noise from either external components or maybe the circuit itself. I have had to install ceramic capacitors to small electric motors before now to cut the excess noise that can affect a servo.

That`s my best guess, hope it helps or at least points you in the right direction. I haven`t built this circuit yet so I can`t comment on the circuits efficacy. I do have some experience of using servos in radio controlled models, both aircraft and cars. Whenever I have experienced servo twitch it has been caused by some form of interference, not necessarily from your circuit but signals from things like refrigerators and the like when tested indoors and in close proximity. The servo tends to glitch and twitch if their is a fault in the rx. Sometimes the servo itself can be faulty. Try another servo. My bet is that its noise from either external components or maybe the circuit itself. I have had to install ceramic capacitors to small electric motors before now to cut the excess noise that can affect a servo.

That`s my best guess, hope it helps or at least points you in the right direction. Konrad - thanks for the thought, but I am an experienced RC aeromodeller and in fact used to own my own model shop. I can guarantee that it is not IF causing the twitch which is exactly the same as when most standard RC RX`s are switched on.

I am at a loss as to next move, I do know how to handle IC`s but this is my first use of a 555 and need someone to point me in a likely direction - please note I have a scope available so can check on what really should be happening. I think this will be my next build. Perhaps you can help me with a question I have regarding the circuit. Into what and where exactly do you plug the servo connector From my experience these can be of a slightly different design, so one plug does not fit every rx.

Surely you don`t have to take the plug of the servo to get it into the circuit. Perhaps I`m missing something from the schematic. A case of `can`t see the wood for the trees`. Hi Konrad - I used a female connector from an unused servo extention lead - simply cut the lead in half and soldered the lead into the respective holes on my circuit board, (please note you can buy female only leads from the better model shops or one of the bigger electronic suppliers), I simply had a lead handy. You are correct saying that there are differences in some servo connections - if you are using either Futaba or JR compatible leads then the circuit shows the correct layout black(brown)= neg.

red=pos. white(yellow, orange)=signal. The positive is usually the centre lead in a flat cable. Also the JR and Futaba plugs are not physically identical even though they are electrically the same. I remove the small ridge on a Futaba plug carefully, it will then fit either system and you only have to make sure that it`s the right way round!

A few of the less popular brands use all black leads, personally I refused to stock these when I had my shop as they were more prone to problems - the only reliable way to check these black leads is to look at the same manufacturers RX and note which lead is which. Finally, if you haven`t got a suitable lead, then providing you are happy to remove the servo plug, 🔗 External reference