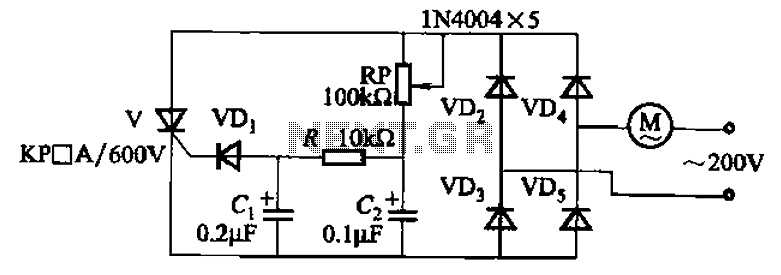

Simple and practical power SCR trigger circuit diagram

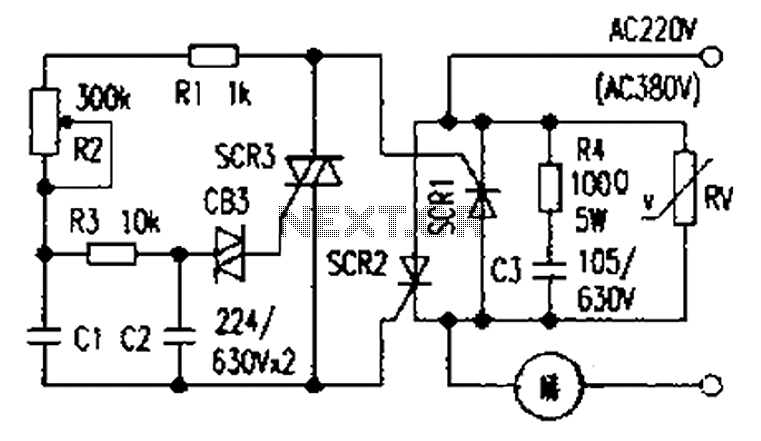

The presentation of a general power thyristor trigger circuit is more complex, and some components are difficult to procure. A successful trigger circuit has been constructed for only a few dollars. This circuit is designed to trigger a thyristor module capable of handling over 100A, suitable for use in an industrial hardening furnace to regulate a voltage of 380V. It is also applicable for controlling a set of high-power variable speed blowers, demonstrating effective performance. Additionally, this circuit can adjust a 220V AC power supply for various electrical appliances. The circuit features two thyristors (SCR1 and SCR2) connected in reverse parallel. A control panel interfaces with this trigger circuit, forming a simple yet practical high-power variable speed control system. A unique aspect of this design is that the SCR gate does not require an external power supply; once the load is energized, a DC voltage pulse ranging from 5V to 8V is generated between the gates and respective cathodes. The conduction angle of the two thyristors can be adjusted by varying the resistance of potentiometer R2, which can effectively block both thyristors when increased to a certain level, functioning as a switch. Another notable feature is the alternating activation of the two main thyristors, preventing reverse breakdown issues. However, if the applied voltage exceeds the transient blocking voltage, SCR1 and SCR2 may inadvertently conduct, with the extent of conduction determined by the potentiometer R2. SCR3, along with surrounding components, forms a general phase-shift trigger circuit, the principle of which is not detailed here. SCR1 and SCR2 are implemented as packaged SCR modules rated at 110A and 1000V, while SCR3 is a BT136 triac rated at 600V. When used with inductive loads, it is advisable to include an RC snubber circuit (R4 and C3) and a varistor (RV) for overvoltage protection, which safeguards against high induced voltages generated by the rapid switching of the load.

The described thyristor trigger circuit is designed to manage high-power applications effectively, particularly in industrial settings. Its architecture allows for precise control of voltage and current, making it suitable for applications that require variable speed regulation. The use of SCRs in reverse parallel configuration ensures that the circuit can handle significant power levels while minimizing the risk of damage due to reverse voltage spikes. The incorporation of the potentiometer R2 serves a dual purpose, allowing for both the adjustment of conduction angles and acting as a safety mechanism by blocking current flow when set to a high resistance.

The circuit's ability to generate a DC voltage pulse at the gate of the SCRs without an external power supply simplifies the design and enhances reliability. This feature is particularly beneficial in applications where space and power availability are limited. Additionally, the inclusion of protective components such as the RC snubber and varistor is crucial for maintaining circuit integrity, especially in environments where inductive loads are prevalent. These components help to dissipate voltage spikes that occur during the switching process, thereby prolonging the lifespan of the SCRs and ensuring consistent performance.

Overall, this thyristor trigger circuit represents a practical solution for controlling high-power loads, with its design emphasizing both functionality and protection against common electrical issues. Books presentation general power thyristor trigger circuit are more complex, and some elements hard to buy. I only spend a few dollars made trigger circuit has been successfull y triggered thyristor module above 100A, industrial hardening furnace for regulating voltage 380V, and for installing a set of high-power variable speed blower for use, the effect is very good. This circuit can also be used to adjust 220V AC power supply with electrical appliances. Circuit shown in Figure. The two-way SCR SCRl, SCR2 reverse parallel. Then the control panel connected to this trigger circuit, on the formation of a simple and practical high-power variable speed circuits.

Unique in this circuit is that the SCR gate without external power supply, as long as the load after power is turned on with this series circuit, the two gate between the respective cathode and there 5V ~ 8V DC voltage pulse generation adjustment potentiometer R2 to change two thyristor conduction angle, increasing the resistance R2 to a certain extent, you can make two main thyristor blocked so the R2 also functions as a switch. Another feature of this circuit is that the two main thyristors alternately turned on, a forward voltage drop is another reverse drop, so there is no reverse breakdown problems.

However, when the applied voltage exceeds the transient blocking voltage, SCR1, SCR2 mislead pass, turned extent decided by the potentiometer R2. SCR3 with the surrounding elements constituting the general phase-shift trigger circuit, the principle is omitted here.

SCR1, SCR2 I use is packaged SCR module (110A/1000V), SCR3 selection BTl36, namely 600V triac. This circuit is used as an inductive load, should increase R4, C3 RC snubber circuit and varistor RV for overvoltage protection, preventing the load off and on instantly generate high induced voltage damage to the SCR.

The described thyristor trigger circuit is designed to manage high-power applications effectively, particularly in industrial settings. Its architecture allows for precise control of voltage and current, making it suitable for applications that require variable speed regulation. The use of SCRs in reverse parallel configuration ensures that the circuit can handle significant power levels while minimizing the risk of damage due to reverse voltage spikes. The incorporation of the potentiometer R2 serves a dual purpose, allowing for both the adjustment of conduction angles and acting as a safety mechanism by blocking current flow when set to a high resistance.

The circuit's ability to generate a DC voltage pulse at the gate of the SCRs without an external power supply simplifies the design and enhances reliability. This feature is particularly beneficial in applications where space and power availability are limited. Additionally, the inclusion of protective components such as the RC snubber and varistor is crucial for maintaining circuit integrity, especially in environments where inductive loads are prevalent. These components help to dissipate voltage spikes that occur during the switching process, thereby prolonging the lifespan of the SCRs and ensuring consistent performance.

Overall, this thyristor trigger circuit represents a practical solution for controlling high-power loads, with its design emphasizing both functionality and protection against common electrical issues. Books presentation general power thyristor trigger circuit are more complex, and some elements hard to buy. I only spend a few dollars made trigger circuit has been successfull y triggered thyristor module above 100A, industrial hardening furnace for regulating voltage 380V, and for installing a set of high-power variable speed blower for use, the effect is very good. This circuit can also be used to adjust 220V AC power supply with electrical appliances. Circuit shown in Figure. The two-way SCR SCRl, SCR2 reverse parallel. Then the control panel connected to this trigger circuit, on the formation of a simple and practical high-power variable speed circuits.

Unique in this circuit is that the SCR gate without external power supply, as long as the load after power is turned on with this series circuit, the two gate between the respective cathode and there 5V ~ 8V DC voltage pulse generation adjustment potentiometer R2 to change two thyristor conduction angle, increasing the resistance R2 to a certain extent, you can make two main thyristor blocked so the R2 also functions as a switch. Another feature of this circuit is that the two main thyristors alternately turned on, a forward voltage drop is another reverse drop, so there is no reverse breakdown problems.

However, when the applied voltage exceeds the transient blocking voltage, SCR1, SCR2 mislead pass, turned extent decided by the potentiometer R2. SCR3 with the surrounding elements constituting the general phase-shift trigger circuit, the principle is omitted here.

SCR1, SCR2 I use is packaged SCR module (110A/1000V), SCR3 selection BTl36, namely 600V triac. This circuit is used as an inductive load, should increase R4, C3 RC snubber circuit and varistor RV for overvoltage protection, preventing the load off and on instantly generate high induced voltage damage to the SCR.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713