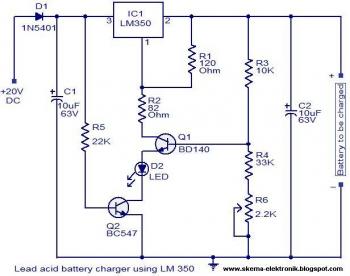

Simple Battery Charger using LM350

The circuit is designed as a constant voltage source with a negative temperature coefficient. The transistor Q1 (BD 140) serves as the temperature sensor, while transistor Q2 prevents battery discharge through resistor R1 when mains power is unavailable. The circuit utilizes the voltage regulator IC LM350, allowing the output voltage of the charger to be adjusted between 13-15 V by varying the potentiometer R6. The LM350 maintains a constant voltage drop of 1.25 V between its input and output pins, ensuring a steady current flow through resistor R1. Q1 functions as a temperature sensor, aided by components R6, R3, and R4, which regulate the base current of Q1. The emitter/base connection of transistor Q1 exhibits a temperature coefficient of -2 mV/°C, resulting in a negative temperature coefficient for the output voltage approximately four times larger, leading to around -8 mV/°C due to the interaction of the emitter/base of Q1 and the division factor of P1, R3, and R4. An LED indicator illuminates whenever mains power is available.

The circuit operates effectively as a constant voltage source, utilizing the LM350 voltage regulator, which is known for its ability to maintain a stable output voltage under varying load conditions. The LM350 is configured to provide an output voltage that can be finely tuned between 13 V and 15 V through the use of potentiometer R6, allowing for customization based on specific application requirements.

Transistor Q1 (BD 140) plays a crucial role in temperature compensation; it acts as a temperature sensor that responds to changes in ambient temperature. The negative temperature coefficient of the output voltage is a result of the inherent characteristics of Q1, which decreases in voltage with increasing temperature. This is further amplified by the circuit configuration involving resistors R3 and R4, which influence the base current and, consequently, the behavior of Q1.

Transistor Q2 functions as a switch that ensures the battery does not discharge through resistor R1 when the mains power is not present, thereby protecting the battery and extending its life. The LED indicator provides a visual cue that mains power is available, enhancing the usability of the circuit.

Overall, this design effectively combines temperature compensation with voltage regulation, making it suitable for applications where stable voltage output is critical in varying temperature environments. The careful selection of components and their configuration allows for precise control over both the output voltage and the thermal behavior of the circuit.The circuit is designed as a constant voltage source with a negative temperature coefficient. The transistor Q1 (BD 140) is used as the temperature sensor. The transistor Q2 is used to prevent the battery from discharging through R1 when the mains power is not available. The circuit is designed based on the voltage regulator IC LM350. The output voltage of the charger can be adjusted between 13-15 V by varying the POT R6. The LM350 will try to keep the voltage drop between its input pin and the output pin at a constant value of 1. 25V. So there will be a constant current flow through the resistor R1. Q1 act here as a temperature sensors with the help of components R6/R3/R4 which more or less control the base current of Q1.

As the emitter/base connection of transitor Q1, just like any other semiconductor, contains a temperature coefficient of -2mV/ °C, the output voltage will also show a negative temperature coefficient. That one is only a factor of 4 larger, because of the variation of the emitter/basis of Q1 multiplied by the division factor of P1/R3/R4.

This results in approximately -8mV/ °C. The LED will glow whenever the mains power is available. 🔗 External reference

The circuit operates effectively as a constant voltage source, utilizing the LM350 voltage regulator, which is known for its ability to maintain a stable output voltage under varying load conditions. The LM350 is configured to provide an output voltage that can be finely tuned between 13 V and 15 V through the use of potentiometer R6, allowing for customization based on specific application requirements.

Transistor Q1 (BD 140) plays a crucial role in temperature compensation; it acts as a temperature sensor that responds to changes in ambient temperature. The negative temperature coefficient of the output voltage is a result of the inherent characteristics of Q1, which decreases in voltage with increasing temperature. This is further amplified by the circuit configuration involving resistors R3 and R4, which influence the base current and, consequently, the behavior of Q1.

Transistor Q2 functions as a switch that ensures the battery does not discharge through resistor R1 when the mains power is not present, thereby protecting the battery and extending its life. The LED indicator provides a visual cue that mains power is available, enhancing the usability of the circuit.

Overall, this design effectively combines temperature compensation with voltage regulation, making it suitable for applications where stable voltage output is critical in varying temperature environments. The careful selection of components and their configuration allows for precise control over both the output voltage and the thermal behavior of the circuit.The circuit is designed as a constant voltage source with a negative temperature coefficient. The transistor Q1 (BD 140) is used as the temperature sensor. The transistor Q2 is used to prevent the battery from discharging through R1 when the mains power is not available. The circuit is designed based on the voltage regulator IC LM350. The output voltage of the charger can be adjusted between 13-15 V by varying the POT R6. The LM350 will try to keep the voltage drop between its input pin and the output pin at a constant value of 1. 25V. So there will be a constant current flow through the resistor R1. Q1 act here as a temperature sensors with the help of components R6/R3/R4 which more or less control the base current of Q1.

As the emitter/base connection of transitor Q1, just like any other semiconductor, contains a temperature coefficient of -2mV/ °C, the output voltage will also show a negative temperature coefficient. That one is only a factor of 4 larger, because of the variation of the emitter/basis of Q1 multiplied by the division factor of P1/R3/R4.

This results in approximately -8mV/ °C. The LED will glow whenever the mains power is available. 🔗 External reference