Simple charge circuit porcelain

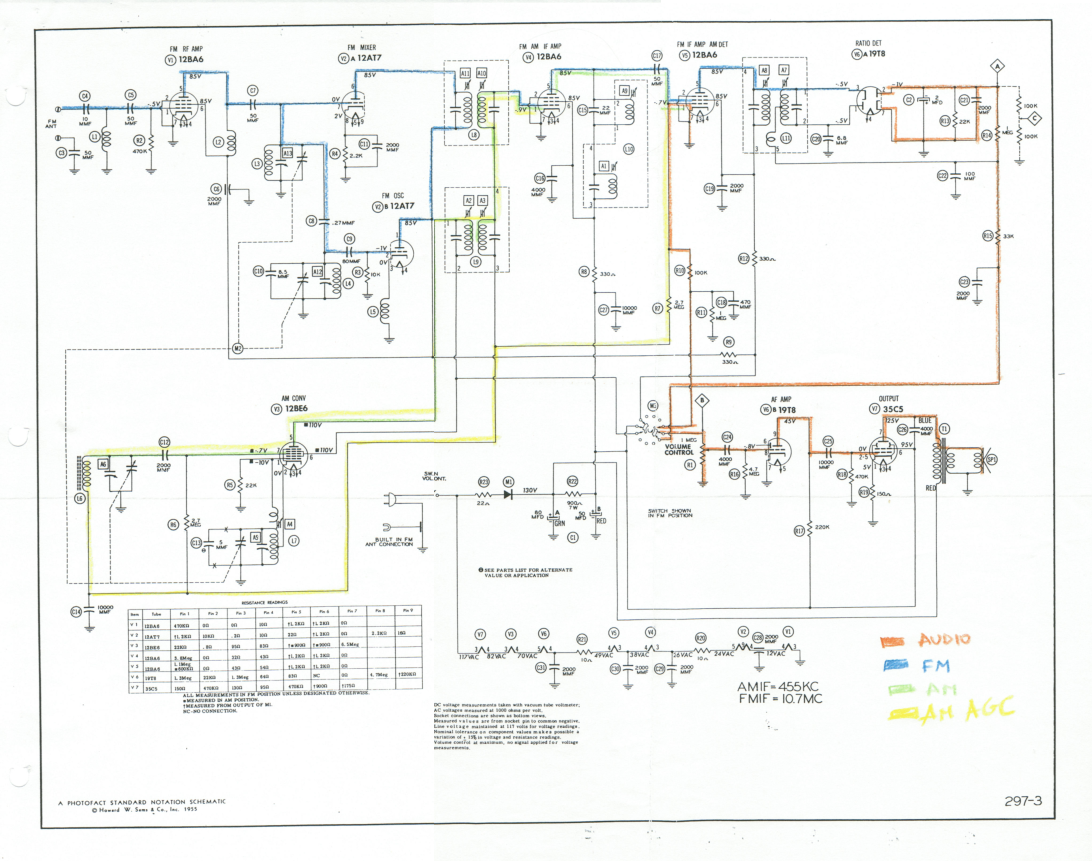

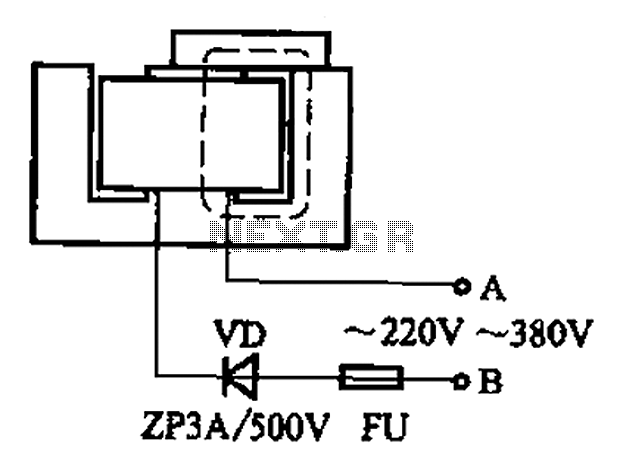

After some minor loss of field magnets, they can be re-magnetized using a homemade method. A scrap of exchanges and contacts, as well as other models like CJ10-60 ~ 15, can be utilized. The circuit operates at 0A (compatible with 220V or 380V). The term "armature" should be omitted, focusing solely on the Yamagata core. Within the coil circuit, there is a fuse and a diode string that form a charge for the porcelain. During the magnetization process, both ends A and B should be connected to a 220V (nominal coil voltage) or 380V (rated coil voltage of 180V) AC power supply, with safety precautions in mind. Sparks may occur upon contact, which should only happen 1 or 2 times. After approximately ten seconds, the system will turn red, and then it should be touched again 1 or 2 times to complete the magnetization process. It is advisable to let the setup stand for several hours before removal to observe the effect.

The described process involves re-magnetizing field magnets by utilizing a homemade setup that incorporates scrap components such as exchanges and contacts. The reference to models like CJ10-60 ~ 15 indicates the versatility of the components used, suggesting that various configurations can be adapted for this application. The operation at 0A implies a low-power design, which is crucial for safety and efficiency, particularly when working with high voltages such as 220V or 380V.

The omission of the term "armature" emphasizes the focus on the Yamagata core, which is likely a specific type of magnetic core material known for its magnetic properties. In the coil circuit, the inclusion of a fuse is essential for protecting the circuit from overcurrent conditions, while the diode string serves to rectify the AC voltage, allowing for controlled charging of the porcelain material used in the magnetization process.

During the magnetization phase, connecting terminals A and B to the AC power supply should be done cautiously, ensuring that safety protocols are strictly followed to prevent electrical hazards. The mention of sparks indicates the presence of high voltage, which necessitates the use of insulated tools and protective gear. The procedure specifies that the connection should only be made a limited number of times (1 or 2), which may relate to the charging cycle of the porcelain material.

Once the system shows a red indication after ten seconds, this likely signifies that the magnetization process is underway. The subsequent touches are part of the procedure to finalize the magnetization effect. Allowing the setup to remain undisturbed for several hours post-magnetization is crucial for the stability and retention of the magnetic properties achieved during the process.

Overall, this method provides a practical approach to re-magnetizing field magnets, leveraging accessible materials and components while highlighting the importance of safety and proper handling of electrical equipment.After some small loss of field magnets can be re-magnetized porcelain filled with homemade simple. Find a scrap of exchanges and contacts, and other models such as CJ10-60 ~ 15 0A (220V or 380V can), remove the word armature, only Yamagata core. In the coil circuit fuse and a diode string, they formed a charge porcelain. When magnetizing, with A, B both ends to touch 220V (nominal coil voltage of 220V) or 380V (rated coil voltage of 180V at) AC power supply (pay attention to safety), there are sparks when touched, just touch 1, 2 times. After ten seconds the red, and then touch 1,2 times, magnetization ends. Then allowed to stand for several hours and then remove (this effect).

The described process involves re-magnetizing field magnets by utilizing a homemade setup that incorporates scrap components such as exchanges and contacts. The reference to models like CJ10-60 ~ 15 indicates the versatility of the components used, suggesting that various configurations can be adapted for this application. The operation at 0A implies a low-power design, which is crucial for safety and efficiency, particularly when working with high voltages such as 220V or 380V.

The omission of the term "armature" emphasizes the focus on the Yamagata core, which is likely a specific type of magnetic core material known for its magnetic properties. In the coil circuit, the inclusion of a fuse is essential for protecting the circuit from overcurrent conditions, while the diode string serves to rectify the AC voltage, allowing for controlled charging of the porcelain material used in the magnetization process.

During the magnetization phase, connecting terminals A and B to the AC power supply should be done cautiously, ensuring that safety protocols are strictly followed to prevent electrical hazards. The mention of sparks indicates the presence of high voltage, which necessitates the use of insulated tools and protective gear. The procedure specifies that the connection should only be made a limited number of times (1 or 2), which may relate to the charging cycle of the porcelain material.

Once the system shows a red indication after ten seconds, this likely signifies that the magnetization process is underway. The subsequent touches are part of the procedure to finalize the magnetization effect. Allowing the setup to remain undisturbed for several hours post-magnetization is crucial for the stability and retention of the magnetic properties achieved during the process.

Overall, this method provides a practical approach to re-magnetizing field magnets, leveraging accessible materials and components while highlighting the importance of safety and proper handling of electrical equipment.After some small loss of field magnets can be re-magnetized porcelain filled with homemade simple. Find a scrap of exchanges and contacts, and other models such as CJ10-60 ~ 15 0A (220V or 380V can), remove the word armature, only Yamagata core. In the coil circuit fuse and a diode string, they formed a charge porcelain. When magnetizing, with A, B both ends to touch 220V (nominal coil voltage of 220V) or 380V (rated coil voltage of 180V at) AC power supply (pay attention to safety), there are sparks when touched, just touch 1, 2 times. After ten seconds the red, and then touch 1,2 times, magnetization ends. Then allowed to stand for several hours and then remove (this effect).