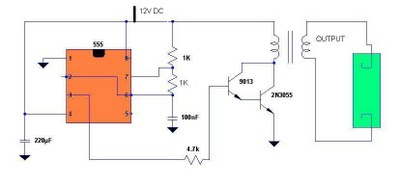

simple fluorescent inverter project

Fluorescent tubes contain mercury, which poses health risks. Improper disposal of these tubes is harmful to both the environment and health; therefore, recycling is a beneficial option. The 555 timer IC is utilized to generate a square wave voltage of approximately 4.8 kHz. The primary winding, consisting of 16 turns of #22 AWG wire, generates current pulses of about 4A. This, in turn, induces a high voltage at the secondary winding, which has 350 turns of #30 AWG wire in the inverter. This induced voltage is sufficient to ignite the fluorescent tube, even if the filament is not heated, making it particularly suitable for tubes with broken or burnt-out filaments.

The circuit employs a 555 timer IC configured in astable mode to produce a continuous square wave signal at a frequency of approximately 4.8 kHz. This frequency is critical for efficient operation, allowing the circuit to provide a rapid on-off cycling that is necessary for the excitation of the gas within the fluorescent tube.

The primary winding of the transformer is constructed with 16 turns of #22 AWG wire. This winding is connected to the output of the 555 timer circuit, which drives the current through the primary coil. The resulting magnetic field generated by the primary winding induces a current in the secondary winding.

The secondary winding, made of 350 turns of #30 AWG wire, is designed to step up the voltage significantly. The ratio of turns between the primary and secondary windings (approximately 21.875:1) allows for a high-voltage output sufficient to strike the gas within the fluorescent tube. This is particularly advantageous for tubes with damaged filaments, as the high-voltage pulse can initiate the ionization process necessary for the tube to operate, even in the absence of a functioning filament.

The circuit's design also ensures that the current pulses generated in the primary winding are limited to approximately 4A, which is an optimal level for preventing overheating and ensuring the longevity of the components used. The use of appropriate wire gauges for both windings is crucial for maintaining efficiency and minimizing losses due to resistance.

In summary, this circuit provides an effective solution for recycling fluorescent tubes by utilizing a 555 timer IC to generate a high-frequency square wave, which drives a transformer to produce the necessary high voltage for tube ignition, thereby addressing both environmental concerns and health risks associated with improper disposal.As we know, fluorescent tube contains mercury that is dangerous to health. improper disposal of this tube is not good to environment and to health, thus recycling is a good choice. The use of 555 timer IC is to generate square wave voltage of about 4. 8kHz and the the primary winding (16 turns of #22 AWG) will generate current pulses of about 4A, an d in return will induce a a high voltage at the secondary winding (350 turns of #30 AWG) of the inverter. This voltage is enough to strike the fluorescent tube even if the filament is not heated thus very suitable to tubes with broken filaments ( burnt out filaments).

🔗 External reference

The circuit employs a 555 timer IC configured in astable mode to produce a continuous square wave signal at a frequency of approximately 4.8 kHz. This frequency is critical for efficient operation, allowing the circuit to provide a rapid on-off cycling that is necessary for the excitation of the gas within the fluorescent tube.

The primary winding of the transformer is constructed with 16 turns of #22 AWG wire. This winding is connected to the output of the 555 timer circuit, which drives the current through the primary coil. The resulting magnetic field generated by the primary winding induces a current in the secondary winding.

The secondary winding, made of 350 turns of #30 AWG wire, is designed to step up the voltage significantly. The ratio of turns between the primary and secondary windings (approximately 21.875:1) allows for a high-voltage output sufficient to strike the gas within the fluorescent tube. This is particularly advantageous for tubes with damaged filaments, as the high-voltage pulse can initiate the ionization process necessary for the tube to operate, even in the absence of a functioning filament.

The circuit's design also ensures that the current pulses generated in the primary winding are limited to approximately 4A, which is an optimal level for preventing overheating and ensuring the longevity of the components used. The use of appropriate wire gauges for both windings is crucial for maintaining efficiency and minimizing losses due to resistance.

In summary, this circuit provides an effective solution for recycling fluorescent tubes by utilizing a 555 timer IC to generate a high-frequency square wave, which drives a transformer to produce the necessary high voltage for tube ignition, thereby addressing both environmental concerns and health risks associated with improper disposal.As we know, fluorescent tube contains mercury that is dangerous to health. improper disposal of this tube is not good to environment and to health, thus recycling is a good choice. The use of 555 timer IC is to generate square wave voltage of about 4. 8kHz and the the primary winding (16 turns of #22 AWG) will generate current pulses of about 4A, an d in return will induce a a high voltage at the secondary winding (350 turns of #30 AWG) of the inverter. This voltage is enough to strike the fluorescent tube even if the filament is not heated thus very suitable to tubes with broken filaments ( burnt out filaments).

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713