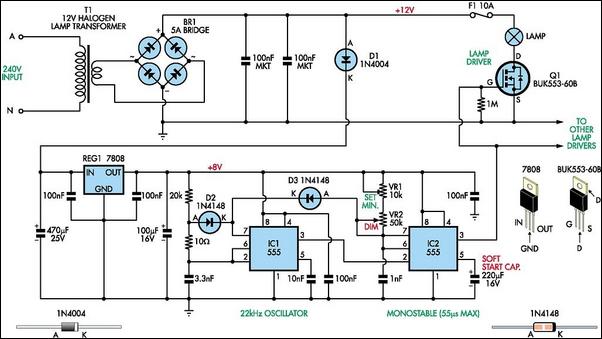

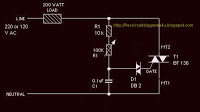

Simple Lamp Dimmer Fan Regulator

The circuit operates by adjusting the firing angle of the Triac. Resistors R1, R2, and capacitor C2 are involved in this process. The firing angle can be modified by changing the value of any of these components, with R1 designated as the variable element. By altering the value of R1, the firing angle of the Triac is adjusted, which determines the duration of conduction for the Triac. This, in turn, affects the power delivered to the load, as the load is controlled by the Triac. Firing pulses are supplied to the gate of Triac T1 through Diac D1. It is recommended to assemble the circuit on a high-quality PCB or a common board. The load, whether it be a lamp, fan, or any other device, should not exceed 200 Watts. For higher loads, it is advisable to replace the Triac BT 136 with a Triac that has a higher wattage capacity. All components of the circuit are active and present a potential shock hazard; caution is advised.

This circuit utilizes a Triac for controlling the power delivered to a load by varying the firing angle. The key components include resistors R1, R2, and capacitor C2, which form a timing network that influences the phase angle at which the Triac is triggered. The variable resistor R1 allows for fine-tuning of the firing angle, which directly correlates to the amount of power delivered to the load. This is achieved by adjusting how long the Triac remains in the conductive state during each AC cycle.

The firing mechanism is facilitated by Diac D1, which ensures that the Triac T1 is turned on at the appropriate moment in the AC waveform. When the voltage across the Diac reaches its breakdown voltage, it conducts, sending a pulse to the gate of the Triac, thus initiating conduction. The timing of this pulse is controlled by the RC timing circuit formed by R1, R2, and C2. As R1 is varied, the delay before the Diac triggers the Triac changes, effectively altering the power delivered to the load.

For assembly, it is crucial to use a quality PCB or a common board to ensure reliability and safety. The circuit is designed to handle loads up to 200 Watts, making it suitable for various applications such as lighting and fan control. However, for loads exceeding this limit, a Triac with a higher voltage and current rating should be utilized to prevent damage and ensure safe operation.

It is important to note that all components in this circuit are live during operation, presenting a risk of electric shock. Proper precautions should be taken when working with the circuit, including ensuring that the power is disconnected during assembly and maintenance. Proper insulation and safe handling practices are essential to mitigate any hazards associated with the high voltages present in the circuit.The circuit works by varying the firing angle of the Triac. Resistors R1, R2 and capacitor C2 are associated with this. The firing angle can be varied by varying the value of any of these components. Here R1 is selected as the variable element. By varying the value of R1 the firing angle of Triac changes (in simple words, how much time should Triac conduct) changes. This directly varies the load power, since load is driven by Triac. The firing pulses are given to the gate of Triac T1 using Diac D1. Assemble the circuit on a good quality PCB or common board. The load whether lamp, fan or any thing, should be less than 200 Watts. To connect higher loads replace the Triac BT 136 with a higher Watt capacity Triac. All parts of the circuit are active with potential shock hazard. So be careful. 🔗 External reference

This circuit utilizes a Triac for controlling the power delivered to a load by varying the firing angle. The key components include resistors R1, R2, and capacitor C2, which form a timing network that influences the phase angle at which the Triac is triggered. The variable resistor R1 allows for fine-tuning of the firing angle, which directly correlates to the amount of power delivered to the load. This is achieved by adjusting how long the Triac remains in the conductive state during each AC cycle.

The firing mechanism is facilitated by Diac D1, which ensures that the Triac T1 is turned on at the appropriate moment in the AC waveform. When the voltage across the Diac reaches its breakdown voltage, it conducts, sending a pulse to the gate of the Triac, thus initiating conduction. The timing of this pulse is controlled by the RC timing circuit formed by R1, R2, and C2. As R1 is varied, the delay before the Diac triggers the Triac changes, effectively altering the power delivered to the load.

For assembly, it is crucial to use a quality PCB or a common board to ensure reliability and safety. The circuit is designed to handle loads up to 200 Watts, making it suitable for various applications such as lighting and fan control. However, for loads exceeding this limit, a Triac with a higher voltage and current rating should be utilized to prevent damage and ensure safe operation.

It is important to note that all components in this circuit are live during operation, presenting a risk of electric shock. Proper precautions should be taken when working with the circuit, including ensuring that the power is disconnected during assembly and maintenance. Proper insulation and safe handling practices are essential to mitigate any hazards associated with the high voltages present in the circuit.The circuit works by varying the firing angle of the Triac. Resistors R1, R2 and capacitor C2 are associated with this. The firing angle can be varied by varying the value of any of these components. Here R1 is selected as the variable element. By varying the value of R1 the firing angle of Triac changes (in simple words, how much time should Triac conduct) changes. This directly varies the load power, since load is driven by Triac. The firing pulses are given to the gate of Triac T1 using Diac D1. Assemble the circuit on a good quality PCB or common board. The load whether lamp, fan or any thing, should be less than 200 Watts. To connect higher loads replace the Triac BT 136 with a higher Watt capacity Triac. All parts of the circuit are active with potential shock hazard. So be careful. 🔗 External reference