Simple MCU-less Differential Motor Drive Circuit

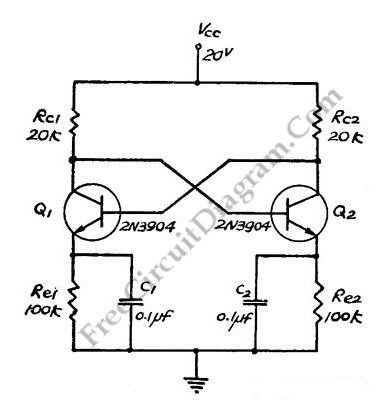

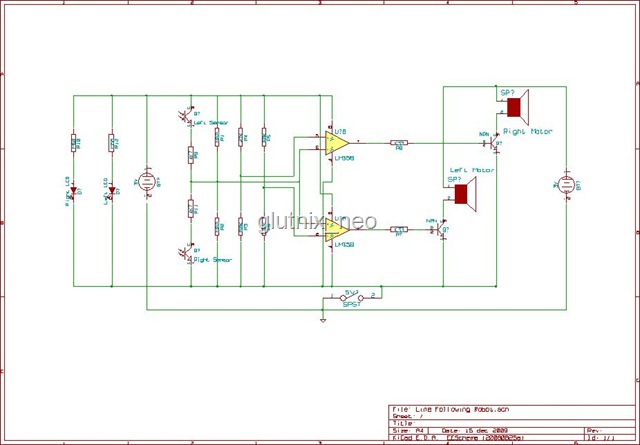

Originally, the tank cost around Php 400 but was later sold for approximately a hundred pesos less. Recognizing a great deal, the decision was made to purchase the toy. Opening the toy proved to be somewhat challenging. The track belt needed to be removed first, and the middle wheels had to be pulled out to access the two screws connecting the tank's upper body to the lower chassis. Inside, there is a small circuit board centered around a surface-mount technology (SMT) integrated circuit. Contrary to expectations, it is not controlled by a microcontroller but rather by a dual comparator integrated circuit, which is pin-compatible with the LM358 (the body marking indicates it is 0358). Within the gearbox, two small DC motors, no larger than a cellphone vibrator motor, drive the tracked wheels differentially, accompanied by a couple of gears. Optical sensors are situated at the bottom, with the main components being phototransistors (the dark part) that detect light reflection (indicating that the surface is not black) from red LEDs (the transparent part). The outputs from the comparator provide the drive signals to turn the tank's motors on or off. The circuit layout is straightforward, as few components are present on the circuit board. The design features a window comparator that deactivates either motor when the voltage produced by the phototransistor divider network exceeds the designated window voltages (typically, the phototransistors are shorted but open when they detect a black line).

The tank's electronic circuit is a simple yet effective design that utilizes a dual comparator to control motor functions based on surface detection. The use of the LM358-compatible comparator allows for reliable performance and ease of integration. The circuit operates by employing a feedback mechanism through the phototransistors, which serve as light sensors. When the red LEDs emit light onto the surface, the phototransistors detect the reflected light. If the surface is light-colored, the reflected light keeps the phototransistors in a conductive state, allowing the comparator to maintain the motors' operation. Conversely, when the sensors detect a dark surface, indicating a black line, the phototransistors open, causing the comparator to deactivate the motors to prevent the tank from veering off course.

The gearbox design, featuring small DC motors, enables agile movement and precise control over the tracked wheels, facilitating maneuverability. The differential drive system allows for sharp turns and adjustments in movement, enhancing the tank's operational capabilities. The simplicity of the circuit board layout aids in troubleshooting and modifications, making it accessible for hobbyists and engineers alike. This design exemplifies an effective application of basic electronic principles to achieve a functional robotic toy, demonstrating the integration of sensors, motors, and control logic in a compact form factor.Originally, the tank cost around Php400 but then it was sold at around a hundred less. Without thinking twice I know I had a great offer so I decided to buy the toy. Opening the toy was quite a bit tricky. The track belt needs to be removed first and the middle wheels must be pulled out to reveal the two screws joining the tank`s upper body to the lower chassis. Inside it is a little circuit board centered around an SMT IC. Guess what it is, a microcontroller Eeeeeh! You`re wrong. It is controlled by a dual comparator IC which is pin to pin compatible with LM358 (the body marking says it`s 0358 ). Inside the gearbox are two small DC motor no bigger than a cellphone vibrator motor that differentially drive the tracked wheels and, of course, a couple of gears.

Optical sensors are located at the bottom. The main part are the phototransistors (dark part) that detect the reflection (indication that the surface is not black) of the light emitted by the red LEDs (transparent part). The outputs of the comparator provide the drive signal to turn on/off the motors of the tank. It was easy to trace the circuit`s layout since few component resides on the circuit board. Looking at the circuit, we can clearly see a window comparator that turns either of the motor off when the voltage produced by the phototransistors divider network goes beyond the window voltages (most of the time phototransistors are shorted but it opens when it senses a black line).

🔗 External reference

The tank's electronic circuit is a simple yet effective design that utilizes a dual comparator to control motor functions based on surface detection. The use of the LM358-compatible comparator allows for reliable performance and ease of integration. The circuit operates by employing a feedback mechanism through the phototransistors, which serve as light sensors. When the red LEDs emit light onto the surface, the phototransistors detect the reflected light. If the surface is light-colored, the reflected light keeps the phototransistors in a conductive state, allowing the comparator to maintain the motors' operation. Conversely, when the sensors detect a dark surface, indicating a black line, the phototransistors open, causing the comparator to deactivate the motors to prevent the tank from veering off course.

The gearbox design, featuring small DC motors, enables agile movement and precise control over the tracked wheels, facilitating maneuverability. The differential drive system allows for sharp turns and adjustments in movement, enhancing the tank's operational capabilities. The simplicity of the circuit board layout aids in troubleshooting and modifications, making it accessible for hobbyists and engineers alike. This design exemplifies an effective application of basic electronic principles to achieve a functional robotic toy, demonstrating the integration of sensors, motors, and control logic in a compact form factor.Originally, the tank cost around Php400 but then it was sold at around a hundred less. Without thinking twice I know I had a great offer so I decided to buy the toy. Opening the toy was quite a bit tricky. The track belt needs to be removed first and the middle wheels must be pulled out to reveal the two screws joining the tank`s upper body to the lower chassis. Inside it is a little circuit board centered around an SMT IC. Guess what it is, a microcontroller Eeeeeh! You`re wrong. It is controlled by a dual comparator IC which is pin to pin compatible with LM358 (the body marking says it`s 0358 ). Inside the gearbox are two small DC motor no bigger than a cellphone vibrator motor that differentially drive the tracked wheels and, of course, a couple of gears.

Optical sensors are located at the bottom. The main part are the phototransistors (dark part) that detect the reflection (indication that the surface is not black) of the light emitted by the red LEDs (transparent part). The outputs of the comparator provide the drive signal to turn on/off the motors of the tank. It was easy to trace the circuit`s layout since few component resides on the circuit board. Looking at the circuit, we can clearly see a window comparator that turns either of the motor off when the voltage produced by the phototransistors divider network goes beyond the window voltages (most of the time phototransistors are shorted but it opens when it senses a black line).

🔗 External reference