simple servo motor controller circuit

The servo motor has numerous applications in various fields, including robotics, puppetry, photography, and more. These compact motors can accurately position their output shaft to any specified angle and maintain that position. Most servos have a motion range of approximately 210 degrees and are relatively simple to control using a basic circuit, such as the one presented here. By utilizing a 555 timer along with a few additional components, this circuit can effectively manage a servo's full rotation based on the position of a potentiometer. The process of creating a printed circuit board (PCB) can be accomplished in straightforward steps. Begin by designing the PCB using software like Eagle. Once the design is complete, print it on photo or glossy paper using a laser printer. Adhere the printed design to the copper side of the PCB and apply heat using a hot iron plate, which will transfer the ink onto the PCB, preparing it for the etching process. If a laser printer is unavailable, the design can be printed on standard paper and copied onto glossy paper at a local copy service.

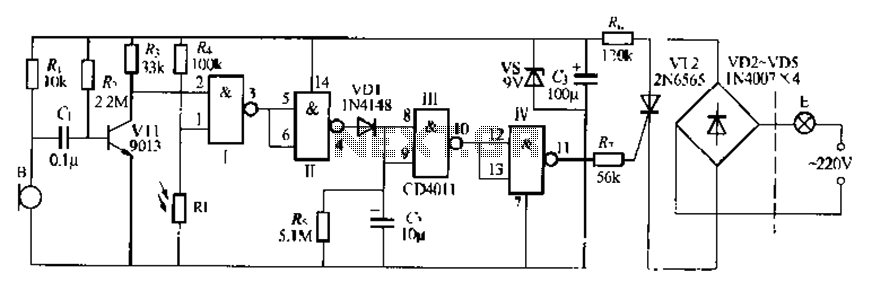

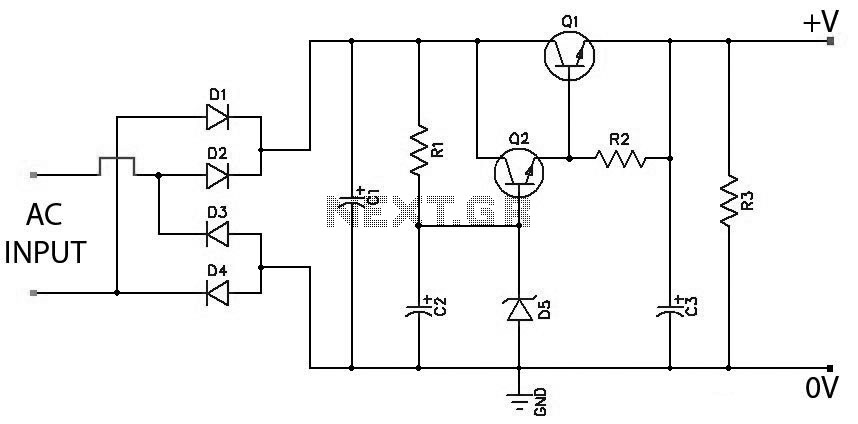

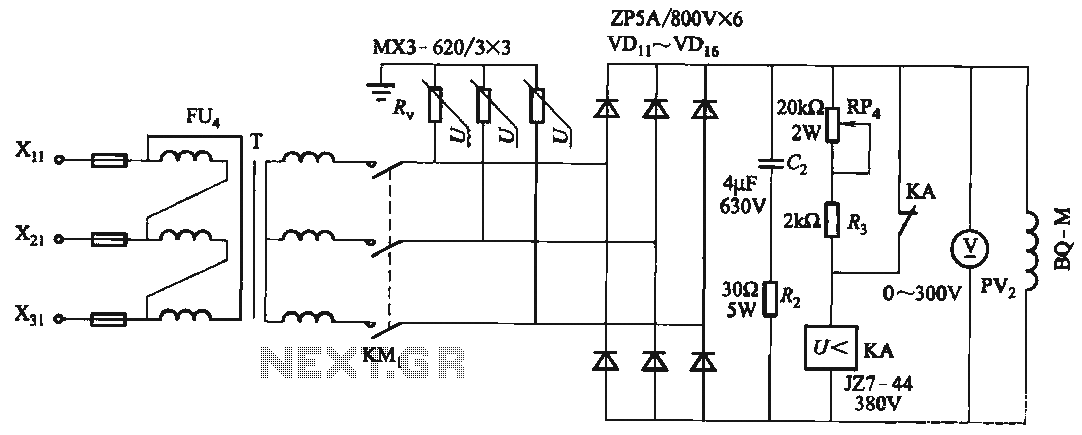

The servo motor is a critical component in many electronic applications due to its precision and reliability in positioning. It operates based on the principles of pulse-width modulation (PWM), where the duration of the pulse sent to the servo determines its angle of rotation. The 555 timer is employed in this circuit to generate the PWM signal, allowing for effective control of the servo's position.

In the circuit, the 555 timer is configured in astable mode, producing a continuous square wave output. The frequency and duty cycle of this signal can be adjusted by varying the resistances and capacitance in the circuit. A potentiometer is integrated into the design, allowing the user to manually set the desired angle of the servo. As the potentiometer is adjusted, it changes the voltage level fed into the control pin of the servo, thus altering its position accordingly.

For the PCB fabrication process, it is essential to ensure that the design is accurate and free from errors. The use of PCB design software, such as Eagle, facilitates the creation of a schematic and layout that can be easily transferred to the PCB. After printing the design, special care must be taken when adhering it to the PCB to avoid air bubbles that could affect the etching quality. The heating process should be done uniformly to ensure that the ink adheres properly to the copper surface.

Following the transfer of the design, the etching process can be initiated, usually involving a ferric chloride solution that removes the unprotected copper, leaving behind the desired circuit traces. Once etching is complete, the board can be cleaned, and components can be soldered onto the PCB, completing the assembly of the servo control circuit. This method provides a cost-effective and efficient way to create custom circuits for various applications involving servo motors.The servo motor have many utilizes in everything from robotics to puppetry to photography and beyond. These tiny motors can position their output shaft to any position on command and hold that position. Most servos possess a range of motion to about 210 degrees and thankfully are quite easy to handle with a basic circuit like the one presented rig

ht here. Working with just a 555 timer as well as a couple of support parts, this circuit can handle a servo via it is full rotation primarily based on the position of a potentiometer. Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer.

Stick the printed design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference

The servo motor is a critical component in many electronic applications due to its precision and reliability in positioning. It operates based on the principles of pulse-width modulation (PWM), where the duration of the pulse sent to the servo determines its angle of rotation. The 555 timer is employed in this circuit to generate the PWM signal, allowing for effective control of the servo's position.

In the circuit, the 555 timer is configured in astable mode, producing a continuous square wave output. The frequency and duty cycle of this signal can be adjusted by varying the resistances and capacitance in the circuit. A potentiometer is integrated into the design, allowing the user to manually set the desired angle of the servo. As the potentiometer is adjusted, it changes the voltage level fed into the control pin of the servo, thus altering its position accordingly.

For the PCB fabrication process, it is essential to ensure that the design is accurate and free from errors. The use of PCB design software, such as Eagle, facilitates the creation of a schematic and layout that can be easily transferred to the PCB. After printing the design, special care must be taken when adhering it to the PCB to avoid air bubbles that could affect the etching quality. The heating process should be done uniformly to ensure that the ink adheres properly to the copper surface.

Following the transfer of the design, the etching process can be initiated, usually involving a ferric chloride solution that removes the unprotected copper, leaving behind the desired circuit traces. Once etching is complete, the board can be cleaned, and components can be soldered onto the PCB, completing the assembly of the servo control circuit. This method provides a cost-effective and efficient way to create custom circuits for various applications involving servo motors.The servo motor have many utilizes in everything from robotics to puppetry to photography and beyond. These tiny motors can position their output shaft to any position on command and hold that position. Most servos possess a range of motion to about 210 degrees and thankfully are quite easy to handle with a basic circuit like the one presented rig

ht here. Working with just a 555 timer as well as a couple of support parts, this circuit can handle a servo via it is full rotation primarily based on the position of a potentiometer. Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer.

Stick the printed design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference