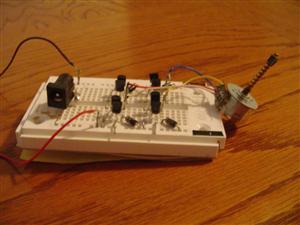

stepper motor controller schematic

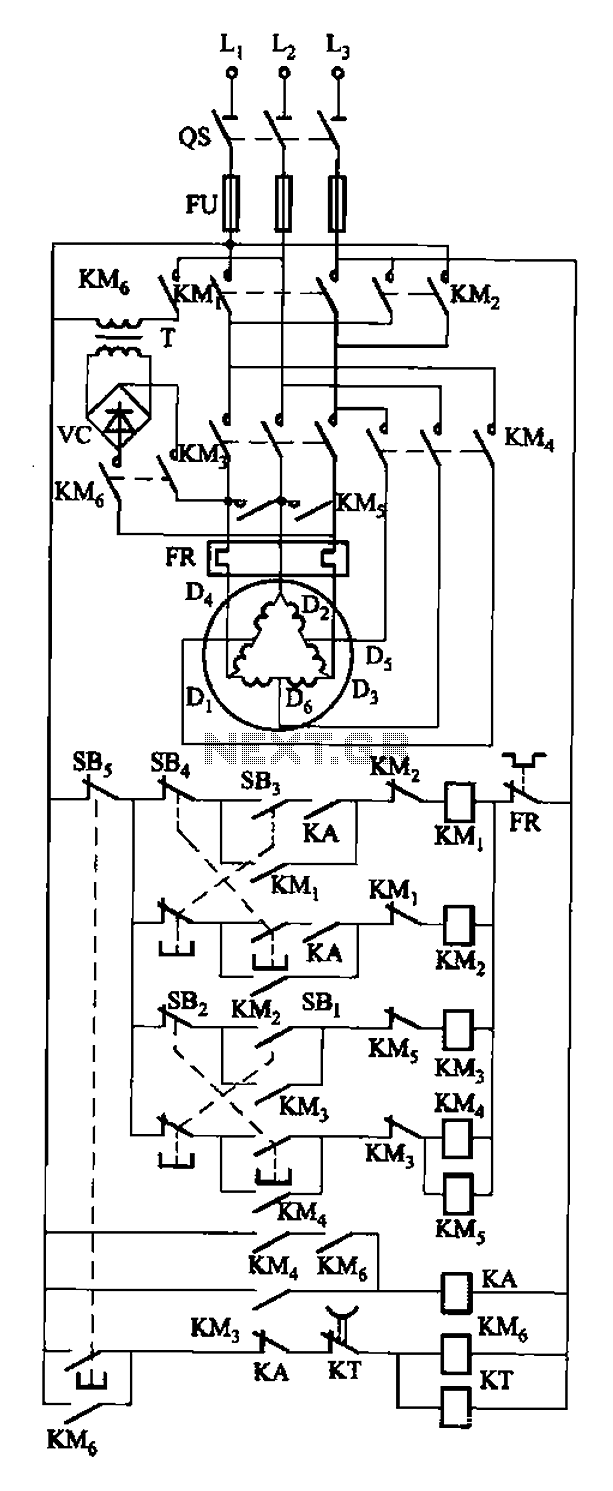

A pulse motor, commonly known as a stepper motor, is defined as a motor that changes its excitation state according to input pulse signals, allowing it to move forward at a specific angle or distance. If the excitation state remains unchanged, the motor will hold its position. Stepper motors are controlled by electrical pulse signals and can be considered a type of brushless DC motor that operates within a certain frequency range, matching the pulse frequency to the synchronous speed of the motor. This description pertains to a two-phase hybrid stepping motor, which utilizes the number of input pulse signals to control displacement without accumulating errors, making it suitable for open-loop control systems such as turret drive control systems. The rectifier board, as illustrated in Figure 1, converts alternating current to direct current to provide the necessary drive. This is achieved through a bridge rectifier circuit, where diodes D2 and D4 conduct during the positive half-cycle, while D1 and D3 block during this phase. Conversely, during the negative half-cycle, D2 and D4 are reverse-biased, and D1 and D3 conduct. The ball screw mechanism operates by converting rotational motion into linear motion, reducing friction significantly compared to traditional screws, enabling high-speed operation with a maximum speed of 200 m/min. The design of a three-phase stepper motor controller employs a GAL16V8 programmable logic device, a sampling unit, and a feedback loop. This controller is characterized by high control precision (up to 2%), low power consumption, high reliability, and the ability to operate independently or under computer monitoring. The modular design allows for integration into various mechanical control systems. Historically, stepper motor controllers utilized discrete components, leading to complexity and unreliability. The introduction of single-board controllers (SBC) like the TP801 faced challenges in industrial applications due to poor anti-interference. However, recent advancements in microcontrollers, particularly the MCS296 family, have provided ideal models for stepper motor control systems. To address previous limitations, the GAL16V8 programmable logic device is employed to develop an efficient sampling feedback control circuit.

The pulse motor, or stepper motor, is a crucial component in various applications that require precise control of angular or linear motion. The operation of a stepper motor is based on the principle of electromagnetic induction, where the motor steps through discrete angles as it receives pulses from a controller. Each pulse corresponds to a specific increment of rotation, allowing for accurate positioning without the need for feedback mechanisms, which is a hallmark of open-loop control systems.

In the context of the two-phase hybrid stepping motor, the design incorporates a stator with multiple windings that are energized in a specific sequence to create a rotating magnetic field. This field interacts with permanent magnets or electromagnetic coils on the rotor, causing it to align with the magnetic field and rotate in discrete steps. The precision of this system is enhanced by the careful control of the pulse frequency, which directly influences the speed and torque of the motor.

The bridge rectifier circuit is an essential part of the power supply for the motor, converting AC voltage from the mains supply into the DC voltage required for operation. The diodes within the circuit are selected based on their forward voltage drop and reverse recovery characteristics to ensure efficient rectification and minimal loss during operation. The rectification process ensures that the motor receives a stable DC supply, which is critical for maintaining consistent performance.

The ball screw mechanism represents a significant advancement in translating rotational motion into linear motion. By utilizing ball bearings within the screw thread, friction is reduced dramatically compared to traditional lead screws, where metal-on-metal contact can lead to excessive wear and heat generation. The rolling motion of the balls allows for smoother and more efficient operation, enabling the system to achieve higher speeds and greater accuracy.

The modular design of the stepper motor controller using GAL16V8 devices allows for flexibility in various applications. This design can be tailored to specific requirements, making it suitable for a wide range of mechanical control systems, from robotics to CNC machinery. The high reliability and low power consumption of the controller ensure that it can operate effectively in demanding industrial environments.

In conclusion, the advancements in stepper motor technology, coupled with innovative control strategies, have led to the development of highly efficient and precise motion control systems. These systems are critical for modern automation and robotics, providing the necessary precision and reliability for a wide array of applications.Pulse motor or stepper motor step motors, foreign, or commonly known as Step motor Stepping motor, Stepper, and so on. To the conventional stepper motor, the stepper motor can be simply defined as, according to the input pulse signal, each time changing the excitation state to move forward at an angle (or length), if not change the excitation state is to maintain

a certain position at rest motor. Broadly speaking, the stepper motor is controlled by the electrical pulse signal brushless DC motor can also be seen as a certain frequency range and control of pulse frequency synchronous speed synchronous motor. Used here is the two-phase hybrid stepping motor, the use of displacement and the number of input pulse signals corresponding to step away from the characteristics of error is not accumulated to form the structure is simple and has a precision open-loop control system, the turret drive control system The operative part.

Physical map shown in Figure 1 Rectifier board is used to rectify alternating current into direct current to provide the drive to use, the principle for the bridge rectifier circuit, the schematic shown in Figure 1 age, D2, D4 closed. Circuit constitutes e2, Dl, Rfz, D3 power circuit, the Rfz, formed under the negative on the positive half-wave voltage of the whole wash, e2 is the negative half-week, on D2, D4 plus the forward voltage, D2, D4 conduction; on D1, D3 reverse voltage, D1, D3 closed.

Circuit constitutes e2, D2 Rfz, D4 power circuit, formed on the same is in Rfz the other under the negative half-wave rectifier voltage. Ball is relative to the original in terms of T-shaped screw th. The principle is the rotational variable translation, screw rotation. Ball screw driven slide the rod. Almost with the principle of the screw, but with the ball only. Turn the screw thwhen the original vice more violent friction, including ths and external ths with the ball between the post to become a rolling friction and improve the friction condition, so that the friction is reduced to the original 1 / 50.

Which also allows it to achieve high speed operation. I see an information display is the highest speed of the screw allows the 200m/min. Catching up motor, produced by Japan, its principle is roughly the nut and screw into the ball room, and then added back to the device on the nut, so the ball rolling in in the loop. Abstract: A three-phase application of CAL device design took six working system stepper motor controller, this controller mainly GAL16V8 programmable logic devices, sampling unit and drive the feedback loop composed of three parts, which is characterized by: control precision high (up to 2%), high-speed low-power, high reliability, can independently control the driver object, but also to work in the computer monitor, the controller uses modular design, it can be used in a variety of mechanical control systems.

As we all know, in the stepper motor control system, mainly by the stepper motor, controller, driver object composed of three parts. Early stepper motor controller using discrete components, hardware circuit complexity, unreliable, bulky, expensive, its parameters for different products need to re-design, promotion and application of much more restricted.

SBC came later, showing a single board to replace the stepper motor controller is a trend, but a class of SBC TP801 poor anti-interference, and difficult to run in the industrial field, so this replaces encountered a new difficult. In recent years, MCS296 family microcontroller birth, especially the 8098 microcontroller and development system was a stepper motor control system provides the ideal models, but the control system development cycle is relatively long, and the cost is still too need to high, in order to overcome these shortcomings, we use an advanced programmable logic devices (PLD) in the GAL16V8 design logic circuits, developed a sampling feedback can au

🔗 External reference

The pulse motor, or stepper motor, is a crucial component in various applications that require precise control of angular or linear motion. The operation of a stepper motor is based on the principle of electromagnetic induction, where the motor steps through discrete angles as it receives pulses from a controller. Each pulse corresponds to a specific increment of rotation, allowing for accurate positioning without the need for feedback mechanisms, which is a hallmark of open-loop control systems.

In the context of the two-phase hybrid stepping motor, the design incorporates a stator with multiple windings that are energized in a specific sequence to create a rotating magnetic field. This field interacts with permanent magnets or electromagnetic coils on the rotor, causing it to align with the magnetic field and rotate in discrete steps. The precision of this system is enhanced by the careful control of the pulse frequency, which directly influences the speed and torque of the motor.

The bridge rectifier circuit is an essential part of the power supply for the motor, converting AC voltage from the mains supply into the DC voltage required for operation. The diodes within the circuit are selected based on their forward voltage drop and reverse recovery characteristics to ensure efficient rectification and minimal loss during operation. The rectification process ensures that the motor receives a stable DC supply, which is critical for maintaining consistent performance.

The ball screw mechanism represents a significant advancement in translating rotational motion into linear motion. By utilizing ball bearings within the screw thread, friction is reduced dramatically compared to traditional lead screws, where metal-on-metal contact can lead to excessive wear and heat generation. The rolling motion of the balls allows for smoother and more efficient operation, enabling the system to achieve higher speeds and greater accuracy.

The modular design of the stepper motor controller using GAL16V8 devices allows for flexibility in various applications. This design can be tailored to specific requirements, making it suitable for a wide range of mechanical control systems, from robotics to CNC machinery. The high reliability and low power consumption of the controller ensure that it can operate effectively in demanding industrial environments.

In conclusion, the advancements in stepper motor technology, coupled with innovative control strategies, have led to the development of highly efficient and precise motion control systems. These systems are critical for modern automation and robotics, providing the necessary precision and reliability for a wide array of applications.Pulse motor or stepper motor step motors, foreign, or commonly known as Step motor Stepping motor, Stepper, and so on. To the conventional stepper motor, the stepper motor can be simply defined as, according to the input pulse signal, each time changing the excitation state to move forward at an angle (or length), if not change the excitation state is to maintain

a certain position at rest motor. Broadly speaking, the stepper motor is controlled by the electrical pulse signal brushless DC motor can also be seen as a certain frequency range and control of pulse frequency synchronous speed synchronous motor. Used here is the two-phase hybrid stepping motor, the use of displacement and the number of input pulse signals corresponding to step away from the characteristics of error is not accumulated to form the structure is simple and has a precision open-loop control system, the turret drive control system The operative part.

Physical map shown in Figure 1 Rectifier board is used to rectify alternating current into direct current to provide the drive to use, the principle for the bridge rectifier circuit, the schematic shown in Figure 1 age, D2, D4 closed. Circuit constitutes e2, Dl, Rfz, D3 power circuit, the Rfz, formed under the negative on the positive half-wave voltage of the whole wash, e2 is the negative half-week, on D2, D4 plus the forward voltage, D2, D4 conduction; on D1, D3 reverse voltage, D1, D3 closed.

Circuit constitutes e2, D2 Rfz, D4 power circuit, formed on the same is in Rfz the other under the negative half-wave rectifier voltage. Ball is relative to the original in terms of T-shaped screw th. The principle is the rotational variable translation, screw rotation. Ball screw driven slide the rod. Almost with the principle of the screw, but with the ball only. Turn the screw thwhen the original vice more violent friction, including ths and external ths with the ball between the post to become a rolling friction and improve the friction condition, so that the friction is reduced to the original 1 / 50.

Which also allows it to achieve high speed operation. I see an information display is the highest speed of the screw allows the 200m/min. Catching up motor, produced by Japan, its principle is roughly the nut and screw into the ball room, and then added back to the device on the nut, so the ball rolling in in the loop. Abstract: A three-phase application of CAL device design took six working system stepper motor controller, this controller mainly GAL16V8 programmable logic devices, sampling unit and drive the feedback loop composed of three parts, which is characterized by: control precision high (up to 2%), high-speed low-power, high reliability, can independently control the driver object, but also to work in the computer monitor, the controller uses modular design, it can be used in a variety of mechanical control systems.

As we all know, in the stepper motor control system, mainly by the stepper motor, controller, driver object composed of three parts. Early stepper motor controller using discrete components, hardware circuit complexity, unreliable, bulky, expensive, its parameters for different products need to re-design, promotion and application of much more restricted.

SBC came later, showing a single board to replace the stepper motor controller is a trend, but a class of SBC TP801 poor anti-interference, and difficult to run in the industrial field, so this replaces encountered a new difficult. In recent years, MCS296 family microcontroller birth, especially the 8098 microcontroller and development system was a stepper motor control system provides the ideal models, but the control system development cycle is relatively long, and the cost is still too need to high, in order to overcome these shortcomings, we use an advanced programmable logic devices (PLD) in the GAL16V8 design logic circuits, developed a sampling feedback can au

🔗 External reference