Stepping motor driver

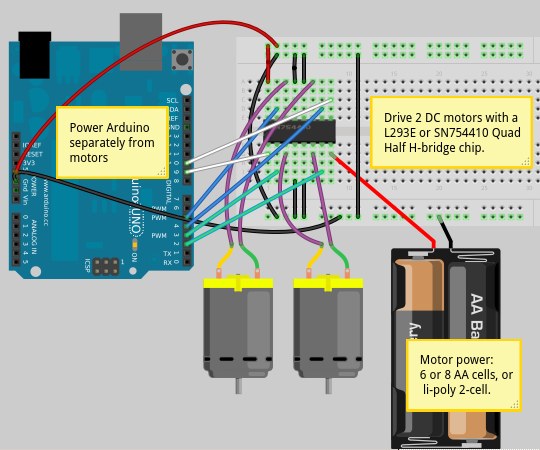

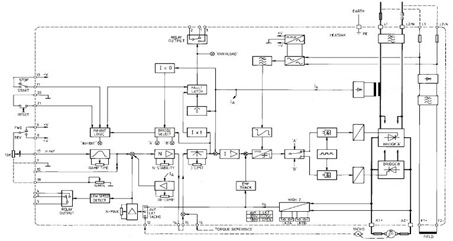

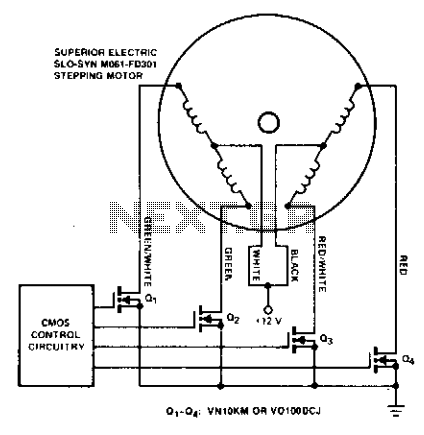

Stepping motors are commonly utilized in disk drives and machine control applications. MOSPOWER transistors serve as excellent motor drivers due to their immunity to second breakdown. It is important to note that snubbing networks are unnecessary since load line shaping is not required with MOSPOWER, and the motor's inductance is relatively low, resulting in minimal inductive spikes. The gates of the MOSFETs are directly connected to the outputs of the CMOS control circuitry. The logic is configured to control the motor in alignment with the specific requirements of the application.

Stepping motors operate by converting electrical energy into precise mechanical movement, making them ideal for applications requiring accurate positioning. The use of MOSPOWER transistors as motor drivers enhances the efficiency and reliability of the system. These transistors are designed to handle high currents and voltages while avoiding the second breakdown phenomenon, which can compromise performance and longevity.

In this configuration, the absence of snubbing networks simplifies the circuit design. Snubbing networks are typically used to mitigate voltage spikes caused by inductive loads; however, with MOSPOWER transistors, such measures are redundant due to their robust design. The relatively low inductance of the stepping motor further minimizes the risk of inductive spikes, allowing for direct interfacing with the control circuitry.

The connection of the MOSFET gates to the outputs of the CMOS control circuitry facilitates seamless operation. CMOS technology offers low power consumption and high noise immunity, making it suitable for controlling the precise sequencing of the stepping motor. The logic is designed to sequence the motor based on the application's specific needs, ensuring optimal performance and responsiveness.

This design approach not only enhances the reliability of the motor control system but also allows for flexibility in application. By tailoring the logic to the particular requirements, various operational modes can be implemented, such as full-step, half-step, or micro-stepping, providing a range of motion control options. Overall, the integration of MOSPOWER transistors and CMOS control circuitry in stepping motor applications represents a robust solution for modern electronic designs.Stepping motors find wide use in disk drives and machine control. MOSPOWER transistors are ideal motor drivers because of their freedom from second breakdown. Note that snubbing networks are not used because load line shaping is not necessary with MOSPOWER and the inductance of the motor is fairly low so that the inductive spike is small. The MOSFET gates are tied directly to the outputs of the CMOS control circuitry. The logic is arranged to sequence the motor in accordance with the needs of the application.

Stepping motors operate by converting electrical energy into precise mechanical movement, making them ideal for applications requiring accurate positioning. The use of MOSPOWER transistors as motor drivers enhances the efficiency and reliability of the system. These transistors are designed to handle high currents and voltages while avoiding the second breakdown phenomenon, which can compromise performance and longevity.

In this configuration, the absence of snubbing networks simplifies the circuit design. Snubbing networks are typically used to mitigate voltage spikes caused by inductive loads; however, with MOSPOWER transistors, such measures are redundant due to their robust design. The relatively low inductance of the stepping motor further minimizes the risk of inductive spikes, allowing for direct interfacing with the control circuitry.

The connection of the MOSFET gates to the outputs of the CMOS control circuitry facilitates seamless operation. CMOS technology offers low power consumption and high noise immunity, making it suitable for controlling the precise sequencing of the stepping motor. The logic is designed to sequence the motor based on the application's specific needs, ensuring optimal performance and responsiveness.

This design approach not only enhances the reliability of the motor control system but also allows for flexibility in application. By tailoring the logic to the particular requirements, various operational modes can be implemented, such as full-step, half-step, or micro-stepping, providing a range of motion control options. Overall, the integration of MOSPOWER transistors and CMOS control circuitry in stepping motor applications represents a robust solution for modern electronic designs.Stepping motors find wide use in disk drives and machine control. MOSPOWER transistors are ideal motor drivers because of their freedom from second breakdown. Note that snubbing networks are not used because load line shaping is not necessary with MOSPOWER and the inductance of the motor is fairly low so that the inductive spike is small. The MOSFET gates are tied directly to the outputs of the CMOS control circuitry. The logic is arranged to sequence the motor in accordance with the needs of the application.